In-House Painting & Silk Screening Service

Your Single-Source Partner for custom enclosures, panels, and metal parts.

We provide a complete in-house solution, from sheet metal fabrication and CNC to durable powder coating and precision silk screening.

- In-House "One-Stop" Process

- Expert DFM & Artwork Review

- Durable Epoxy & Powder Coat Finishes

Stop Juggling Vendors. We Are Your Single-Source Partner.

The Old Way: Multi-Vendor Chaos

Risk of errors, color mismatch, and logo peeling. When quality fails, your sheet metal vendor blames the painter, and the painter blames the silk screener. You're left with project delays and costly rework.

Our In-House Solution

We take full accountability. Our in-house sheet metal fabrication, powder coating, and silk screening processes are fully integrated. This guarantees part quality, finish compatibility, and faster prototype lead times.

From Fabrication to Finished Part

We are your single-source partner. See how our integrated process transforms raw sheet metal and CNC blocks into fully finished, branded components ready for assembly.

Custom Electronics Enclosure

In-house sheet metal fabrication, finished with a textured matte black powder coat and a crisp white epoxy silk-screened logo.

Rackmount Audio Interface Panel

Precision CNC machining for cutouts, a clear brushed anodized finish, and high-resolution multi-color silk screening for all port labels.

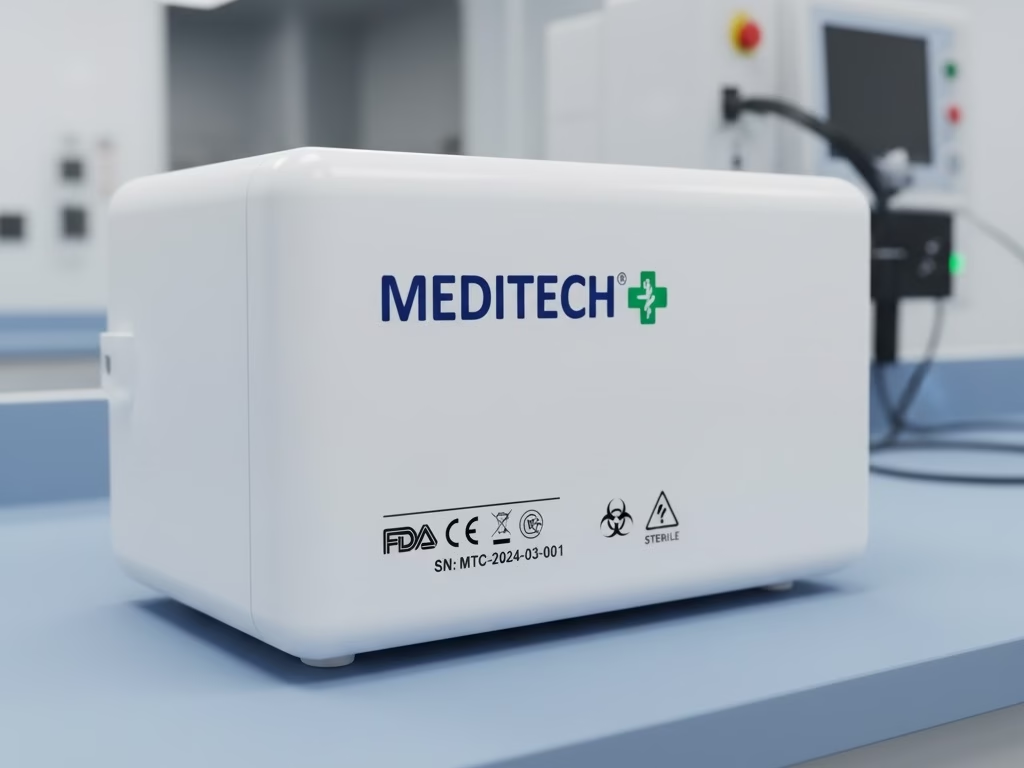

Medical Device Housing

Medical-grade industrial liquid painting on a plastic housing, finished with chemical-resistant silk screening for logos and compliance marks.

Industrial Machine Chassis

Heavy-gauge steel fabrication, coated in a durable "safety yellow" powder coat, and marked with permanent epoxy silk-screened warnings.

CNC Milled Amplifier Housing

Precision CNC milling, followed by bead blasting and a dark grey anodized finish, and completed with subtle, precision silk screening.

Mil-Spec Defense Component

CNC machining, application of a Mil-Spec CARC liquid paint, and durable part marking with UID codes via silk screening.

Our In-House Finishing Capabilities

Our processes are integrated. We ensure your paint finish is perfectly prepped for flawless silk screen adhesion, delivering a single, durable, finished part.

Durable Powder Coating & Liquid Painting

A high-quality finish is the foundation for a durable part. Our in-house industrial painting service is optimized not just for aesthetics, but to create the perfect, chemically-prepped surface treatment for maximum silk screen adhesion.

Powder Coating: Our Recommended Solution

This is our specialty for a reason. For metal enclosures, panels, and chassis, powder coating provides a hard, thick, and cost-effective finish that is far superior to standard wet paint. It offers exceptional resistance to scratches, chips, and chemicals, making it the default choice for industrial, medical, and audio-visual equipment.

How It Works: A dry powder polymer is electrostatically applied to your grounded aluminum or steel part. The part is then cured in a high-temperature oven, melting the powder into a seamless, tough, and uniform skin.

Why It’s Better for Silk Screening: Unlike wet paint, powder coating provides a consistent, textured (or smooth) surface that is ideal for bonding with our 2-part epoxy inks. Our integrated process ensures the surface is perfectly cured and prepped for the next stage.

Key Powder Coating Capabilities:

Finish Textures: We stock a wide array of options to match your design:

Textured (Sandtex): Our most popular choice. Excellent durability and hides fingerprints (ideal for panels and enclosures).

Smooth: For a clean, modern aesthetic.

Matte / Flat: A non-reflective, professional finish.

Semi-Gloss / Gloss: High-shine finishes available upon request.

Color Matching:

Standard Colors: We stock standard RAL colors (e.g., Black, White, Grays) for rapid turnaround.

Custom Colors: Full custom color matching is available for your specific brand requirements.

Pre-treatment: All parts undergo a thorough cleaning and chemical pre-treatment (like iron or zinc phosphate) to ensure maximum coating adhesion and prevent corrosion.

Liquid Painting (Wet Paint) & Mil-Spec

For highly specific applications where powder coating isn’t suitable, our liquid painting line provides precision finishes.

When to Use Liquid Paint:

Mil-Spec Compliance: Required for many defense and aerospace projects. We are experienced in Mil-Spec coating and CARC (Chemical Agent Resistant Coatings).

Material Constraints: For parts that cannot withstand the high-curing heat of powder coating (e.g., certain plastics or pre-assembled components).

Specialized Properties: When you need EMI/RFI shielding (conductive paint) or specific tactile “soft-touch” finishes.

Common Substrates We Finish:

Aluminum (6061, 5052, etc.)

Steel (Cold-Rolled, Stainless Steel)

Plastics (ABS, Polycarbonate)

Crisp Graphics & Markings with Epoxy Inks

Part marking is the critical final step of your fabrication. It represents your brand image (Logo) and your user interface (port labels, safety warnings). A graphic that peels, scratches, or blurs makes an entire well-made part feel cheap and unreliable.

Our precision silk screen printing service is engineered specifically to solve this challenge.

The Epoxy Ink Standard: Our Durability Guarantee

Printing on metal or powder-coated surfaces cannot be done with standard inks. We exclusively use 2-Part Epoxy Inks as the industry gold standard.

How It Works: This isn’t just ‘printing’; it’s a chemical bonding process. The epoxy ink is mixed with a catalyst (hardener) and then cured (via heat or time). This forms a permanent, cross-linked chemical bond to the surface of your part.

The Result: Ultimate adhesion. It cannot be scraped off with a fingernail, will not peel at the edges, and resists solvents, oils, and cleaning agents.

This is the only method we trust to achieve a permanent bond on textured powder-coated surfaces.

Design, Process & Quality Control (DFM)

Our success comes from integrating design, ink, and substrate into a single process.

1. Artwork & DFM Review: We don’t just “print files.” Before production, our DFM team reviews your vector files (

.ai,.pdf,.eps). We will advise on minimum line thickness and font size to ensure your graphics are crisp and legible, even on the most textured surfaces.2. Process Control (Mesh Count): We match the precise mesh count and ink viscosity to your chosen coating (smooth vs. textured). This prevents ink ‘bleeding’ and ensures your custom graphics have razor-sharp edges.

3. Quality Validation (Adhesion Testing): We regularly perform rigorous adhesion testing (such as the Cross-Hatch Test, per ASTM D3359) to validate the bond strength between the ink and the coating, guaranteeing industrial-grade scratch resistance.

Common Silk Screening Applications:

Logos & Corporate Branding

Front Panel Markings & Port Labels

Safety Warnings & Compliance Marks (CE, UL)

Serial Numbers & Part Numbers

Schematic Diagrams & Instructions

Key Capabilities:

Ink Type: High-Adhesion 2-Part Epoxy Inks

Process: Precision screen printing on metal and plastic

Substrates: Optimized for Powder Coated, Painted, and Bare Metal (Aluminum, Steel) surfaces.

Our Integrated "One-Stop" Process

We eliminate risk by controlling every step. Your part never leaves our facility, ensuring quality, accountability, and speed. This seamless workflow means no communication gaps, no transit delays, and a single point of contact for your entire project.

1

2

3

4

Fabrication

In-house sheet metal and CNC fabrication from raw metal.

Painting & Finishing

In-house powder coating and liquid painting in our controlled booths.

Silk Screening & Graphics

Finished parts are silk-screened in-house with durable epoxy inks.

Final Inspection & QA

Final QA checks include adhesion testing and color verification.

Our Finishing Quality & Equipment

Precision in finishing isn’t just about the machine; it’s about the environment and the validation process. We provide the tangible evidence and process control needed to guarantee your finish meets all technical specifications.

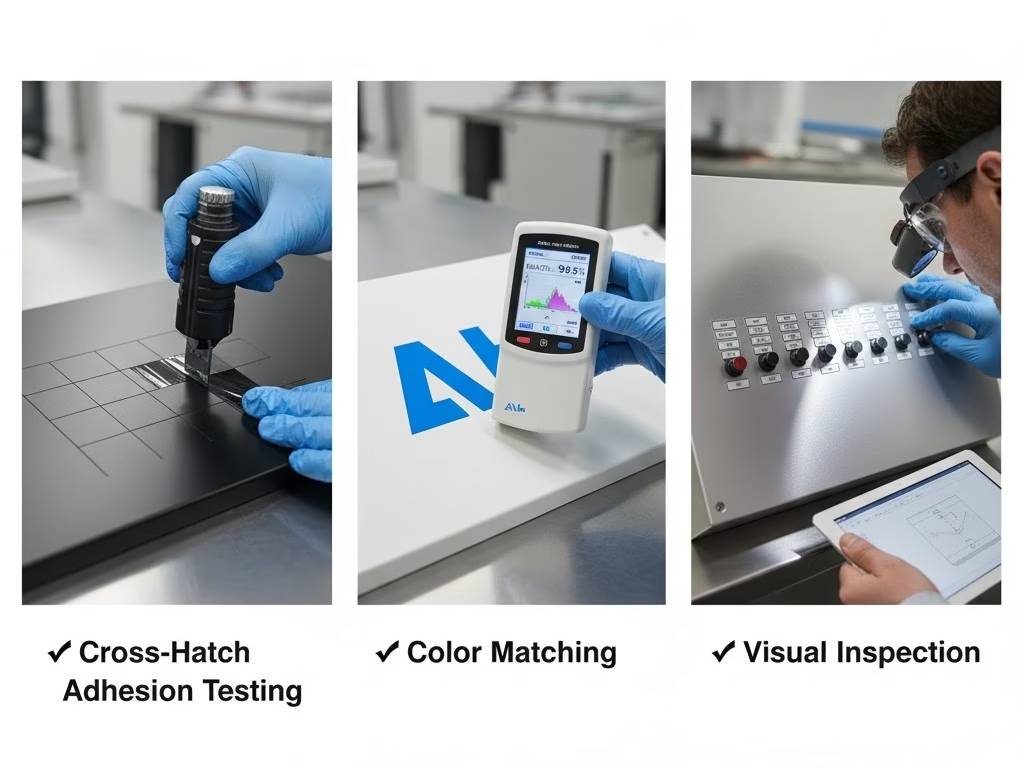

How We Verify Your Finish

We don't guess; we test. Our quality process includes:

- ✔ Cross-Hatch Adhesion Testing: We perform ASTM D3359 adhesion tests to guarantee your graphics and paint will never peel or flake.

- ✔ Color Matching: Using digital spectrometers, we ensure your brand colors are matched perfectly time.

- ✔ Visual Inspection: Every part is inspected for surface uniformity, blemish-free finishes, and crisp graphic alignment.

Our Finishing Environment

A flawless finish requires a flawless environment. Our facility includes:

- ✔ Dust-Free Paint Booths: Climate-controlled booths prevent airborne particles from contaminating the finish.

- ✔ High-Temperature Curing Ovens: Precisely controlled ovens ensure your powder coat and epoxy inks are cured to their maximum hardness and durability.

- ✔ Precision Screen Printing Rigs: Stable, high-precision rigs ensure perfect registration and edge definition for your logos and labels.

Expert Insights & Resources

Common Questions About Painting & Screen Printing

We’ve compiled answers to the most common technical and commercial questions our engineering and procurement partners ask about our integrated finishing services.

Silk screening uses a stencil and durable epoxy inks, making it exceptionally durable and cost-effective for 1-3 color designs, especially on textured surfaces. Digital printing is like an inkjet printer, better for complex, multi-color images but may have lower adhesion on some finishes.

Yes, this is our specialty. We control the mesh count and epoxy ink viscosity to ensure sharp, crisp edges, even on textured powder coat surfaces.

For painted or coated parts, 2-part epoxy ink is the industry standard for durability, chemical resistance, and scratch resistance.

We match the correct epoxy ink to your substrate (aluminum, plastic) and finish (powder coat, anodized). This pairing is validated by our adhesion testing to guarantee chemical and scratch resistance.

We require vector files (.ai, .pdf, .eps). Our DFM team reviews them to confirm minimum line thickness and registration requirements are met.

As a one-stop shop, we are much faster than multi-vendor solutions. Turnaround depends on complexity, but because fabrication and finishing are in-house, we eliminate transit delays. Contact us for a project-specific timeline.

We support projects from rapid prototyping and low-volume manufacturing to full production. We are flexible and do not have a high MOQ, making us ideal for prototype runs.

Ready for a Flawless Finish?

Let’s discuss your project.

Upload your CAD or Artwork files, and our engineers will provide a detailed quote and DFM review.

Take the first step today !

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.