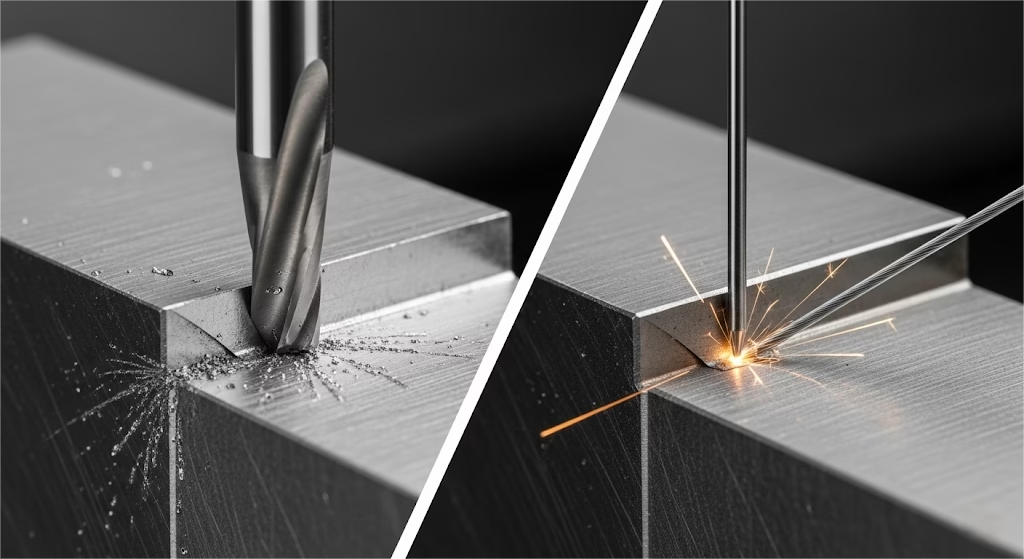

Precision Wire Cutting Service (EDM)

Empower your most ambitious designs. Our precision wire cutting services give you the freedom to create parts with razor-sharp internal corners, complex shapes, and superior finishes, even in hardened tool steel.

- Intricate Internal Features

- Cut Any Conductive Material

- No-Stress & Burr-Free

Machining Without Limits

Wire cutting (EDM) is a non-contact thermal process that uses an electrically charged wire to cut conductive materials. A series of controlled sparks precisely erode the material—like a high-tech, digital bandsaw that never touches the part.

Our Wire Cutting Capabilities at a Glance

Our state-of-the-art wire cutting machines operate in a temperature-controlled environment to deliver exceptional precision. We offer both low-speed and high-speed options to match your project’s specific needs.

|

Feature

|

Zenithin's Specification

|

|---|---|

|

Process Types |

Low-Speed (for high precision & finish), Fast-Speed (for efficiency) |

|

Highest Tolerance |

±0.002mm |

|

Surface Roughness (Ra) |

As fine as 0.2 μm (via low-speed cutting) |

|

Min. Internal Corner Radius |

As small as 0.1mm |

|

Materials |

All Conductive Materials: Hardened Tool Steel, Tungsten Carbide, etc. |

|

Industries Served |

Tool & Die Making, Mold Manufacturing, Aerospace, Medical |

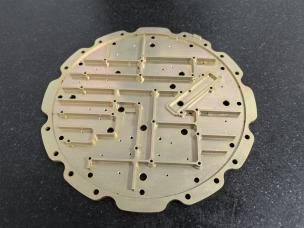

Wire Cutting Project Showcase

From tool steel dies to precision magnesium components, our wire cutting services provide solutions where other processes fail.

Precision-Split Aluminum Pulling Rod

precisely split into 6 equal segments using **low-speed Wire Cutting** for a perfect, burr-free cut.

Magnesium Alloy Electronic Septum

High-speed Wire Cutting was utilized to cut the entire complex shape in a single, efficient operation.

Hybrid-Machined Magnesium Mounting Plate

A pedestal mounting plate made from magnesium alloy, where high-speed Wire EDM first profiled the outer contour, followed by 3-axis CNC milling to complete the final features.

Precision-Split Aluminum Pulling Rod

A 7071 aluminum rod, first CNC turned to a fine finish, then precisely split into 6 equal segments using low-speed Wire EDM for a perfect, burr-free cut.

Impressed by Our Work? Let's Build Yours

We are ready to apply the same precision and commitment to quality to your project. Upload your design files to get started with a free, no-obligation quote from our expert engineers.

PRECISION

Powered by Advanced Wire Cutting Technology

Our workshop is equipped with state-of-the-art wire cutting machines (EDM). This non-contact technology allows us to achieve unparalleled accuracy

.avif)

Drilling machine for drilling processing

Drilling machine for drilling processing

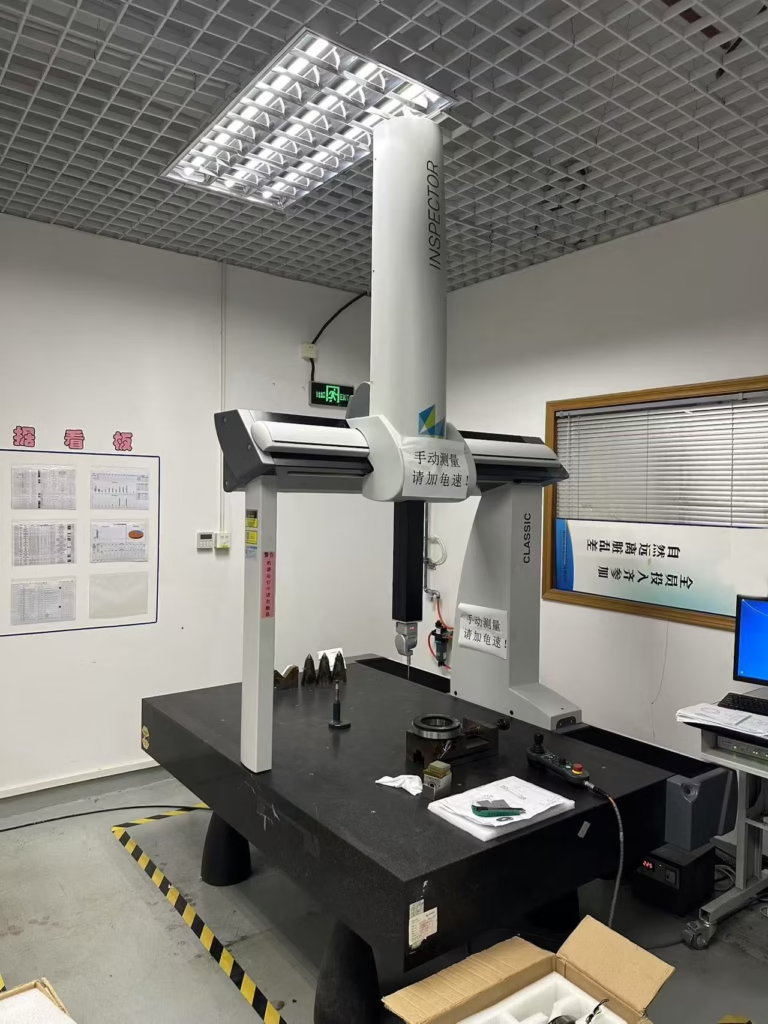

Precision, Verified.

The extreme accuracy of our wire cutting process is confirmed in our quality lab. Every critical feature is verified on our high-precision CMM

High-precision Digital Height Gauge

Three-dimensional Measuring Instrument

Three-dimensional Measuring Instrument

Your Wire Cutting Questions, Answered

Find answers to common technical questions about our Wire EDM services below.

We can cut any material that is electrically conductive. This includes all common metals like aluminum and steel, as well as exotic alloys and ultra-hard materials like tungsten carbide.

Wire cutting is generally more precise, can cut much thicker parts, and leaves a superior surface finish with no heat-affected zone (HAZ). Laser cutting is typically faster for thin sheet metal applications.

Yes. To cut a fully enclosed internal shape (like a square hole), a small "start hole" must be drilled first for the wire to pass through. We can manage this for you as part of the process.

While the cutting speed itself is moderate, for complex parts made from hardened materials, wire cutting is often the most cost-effective overall solution because it eliminates multiple setups and the need for secondary finishing.

The minimum radius is determined by the wire's diameter plus the spark gap. We can typically achieve true, sharp corners with a radius as small as 0.1mm, which is impossible for any traditional milling process.

It's a very thin layer of re-solidified material on the cut surface. We control its thickness and integrity by using multiple fine-finishing "skim cuts" and optimizing power settings, ensuring it's suitable for even the most demanding applications.

Ready to Machine the Impossible?

For parts with features too complex or materials too hard for conventional machining, wire cutting is the definitive solution. Upload your design and challenge our experts.

Take the first step today !

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.