Staring at a tight tolerance on a blueprint and wondering if your CNC milling process can handle it? You’re in the right place. This is the no-fluff, data-backed guide to making the right call between milling and grinding, ensuring you get it right the first time.

Precision grinding is necessary when a component requires dimensional tolerances stricter than ±0.01mm, a surface finish finer than Ra 0.8μm, or final shaping after the part has undergone heat treatment. These requirements exceed the reliable capabilities of even the most advanced CNC milling operations.

Now that you have the direct answer, it’s time to dive into the specifics. We’ll break down the hard data, compare the total cost of grinding per hour versus the risk of a failed milling pass, and even look at how grinding stacks up against alternatives like lapping and hard turning. Read on to see the case studies and analysis that will make you a more confident decision-maker.

Understanding the Limits: What CNC Milling Can Realistically Achieve

Before deciding on a process, it’s essential to have a clear, data-driven understanding of what CNC milling can reliably deliver. While it’s a versatile and powerful technology, it has its limits, especially when high-precision machining is paramount.

Dimensional and Geometric Tolerances

For dimensional accuracy, a top-tier 5-axis CNC machining process can stably and repeatedly hold a tolerance of ±0.01mm (or 10 µm). While it’s sometimes possible to push this to a “hero cut” limit of ±0.005mm, this often requires a climate-controlled environment and slow machining speeds, making it impractical for volume production.

When it comes to the shape of the part, the limits are just as important:

| Geometric Tolerance | Top-Tier Milling Capability |

|---|---|

| Roundness | 0.005 mm |

| Cylindricity | 0.008 mm |

| Flatness | 0.01 mm / 100mm |

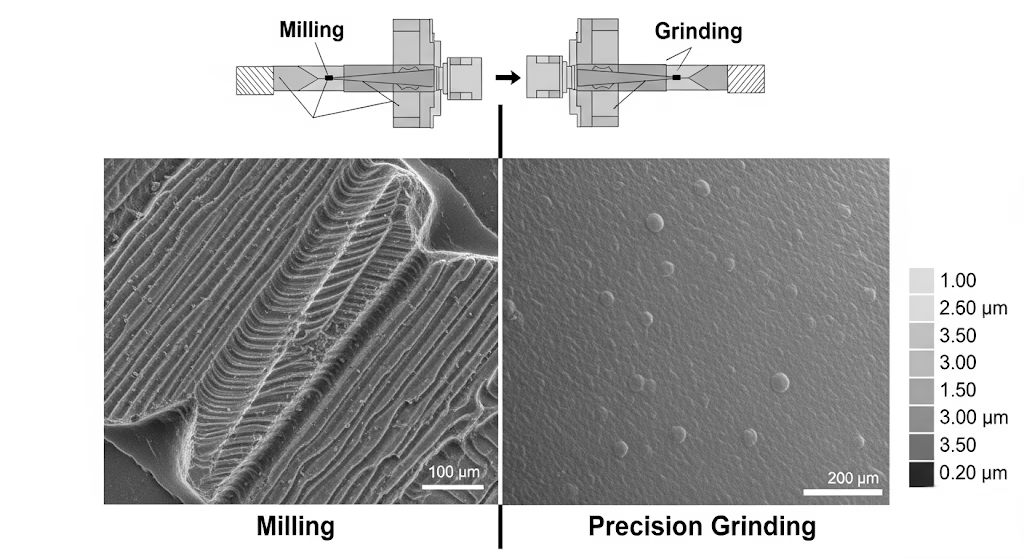

Surface Finish and Hard Materials

In terms of surface finish, milling can consistently produce a high-quality surface of Ra 1.6 µm. With specialized tooling and optimized strategies, it can reliably achieve a limit of Ra 0.8 µm. Pushing for a finer finish, such as Ra 0.4 µm, often becomes inconsistent and uneconomical.

Material hardness is another key factor. Conventional milling is best suited for materials with a hardness of up to HRC 45. For processing hard materials, a process known as hard milling can be used, and our playbook for machining hardened steels provides a comprehensive guide to overcoming its unique challenges.

If your requirements exceed these benchmarks, it’s a strong signal that you need to look beyond milling.

Three Triggers: When Grinding Becomes a Necessity

So, when do you draw the line and say, “This is a job for grinding”? Understanding the applications requiring precision grinding is critical here. It often comes down to three clear signals where the risks of sticking with milling outweigh the costs of upgrading.

1. When Part Function Demands It

Sometimes, the blueprint’s numbers don’t tell the whole story, but the part’s job does. If your component is critical for dynamic sealing (like a hydraulic valve spool) or must endure high-cycle fatigue (like a bearing shaft), the quality of the surface is paramount.

Milling leaves behind a pattern of tool marks, which, even if they meet the Ra value, can create a path for leaks or become initiation points for micro-cracks. Grinding creates a non-directional, random surface that is far superior for both sealing and fatigue life.

2. When Performance Hinges on Surface Integrity

Beyond a simple roughness number, there’s a deeper concept called surface integrity. This includes the residual stress left in the material after machining. Hard milling, while effective, introduces significant tensile residual stress into the part’s surface, often between +200 to +800 MPa. This pulling stress acts like a built-in weakness, making the part much more susceptible to fatigue failure.

For parts that absolutely cannot fail, the difference between milling’s tensile stress and grinding’s beneficial compressive residual stresses (from -100 to -500 MPa) is a game-changer. This “squeezing” stress actively works to hold the surface together, inhibiting cracks from forming.

3. When Heat Treatment Is Involved

This is perhaps the most non-negotiable trigger. If your part needs to be heat-treated to a hardness above HRC 50 for strength and wear resistance, you must plan for grinding. The heat treatment process, while necessary, inevitably causes the material to warp and distort on a micro-level.

We once worked on a project for a medical device where the parts were milled to perfect dimensions before heat treatment. After hardening, they were still technically within tolerance, but microscopic distortion led to friction during assembly. The only solution was to re-process the parts with grinding to correct these small deformities.

This is why experienced designers always leave a material allowance—typically 0.15mm to 0.25mm per side—for a final grinding pass after heat treatment. It’s the only reliable way to restore the perfect geometry required by our rigorous quality control process.

The Business Case: Justifying the ROI of Grinding

Presenting a higher-cost option to your purchasing manager can be challenging. The initial price for grinding is almost always higher than for milling. However, the conversation changes when you shift the focus from the initial price tag to the total cost of a successfully completed part.

A myopic focus on a lower hourly rate can be misleading. As industry observer Peter Zelinski of Modern Machine Shop magazine often notes, experienced manufacturers compare the total cost of success. For a critical part, the reliability of grinding isn’t a luxury; it’s an economic strategy to eliminate risk.

Let’s quantify this with a simple model:

Total Cost = Machining Cost + (Part’s Current Value x Scrap Rate %)

Imagine a precision mold core. By the time it’s ready for its final finishing pass, it has already accumulated $200 in material and prior machining costs.

- Option A (Hard Milling): The machining cost is $40. But due to the tight tolerances, there’s a reasonable 10% risk of scrapping the part.

- Risk Cost = $200 x 10% = $20

- Total Adjusted Cost = $40 (machining) + $20 (risk) = $60

- Option B (Grinding): The machining cost is higher, at $70. However, the process is so reliable that the scrap rate is virtually zero.

- Total Adjusted Cost = $70

Suddenly, the cost difference doesn’t seem so large. Now, consider the “secondary costs” that don’t appear on the quote. A part at the edge of its tolerance might require an extra 30 minutes of a skilled technician’s time for hand-fitting during assembly.

When you factor in these downstream costs from assembly, warranty, and brand reputation, the higher initial investment in grinding often proves to be the more economical choice.

A Look Ahead: Future Trends and Your Supply Chain

The lines between milling and grinding are beginning to blur, and this shift has important implications for both design and procurement. On one hand, advanced hard milling techniques are pushing the boundaries of what milling can achieve.

On the other, the rise of milling-grinding hybrid machines from manufacturers like DMG Mori and Matsuura is changing the game entirely. These machines can perform both complex milling and high-precision grinding in a single setup, eliminating the inaccuracies that can occur when moving a part between different machines.

For you as an engineer, this opens up new possibilities for designing complex, highly precise components that were previously impractical. For your procurement team, it introduces a new, higher-level criterion for vetting suppliers: do they have single-setup manufacturing capabilities?

However, this also highlights a critical supply chain risk. While almost any machine shop has a CNC mill, true grinding expertise—complete with temperature-controlled environments, advanced inspection equipment, and highly skilled operators—is a rare resource.

A supplier’s grinding capability often rests on the shoulders of one or two veteran engineers. When you evaluate a new manufacturing partner, go beyond their machine list and ask them, “How many senior grinding engineers do you have?” and “What is your process for knowledge transfer?” Securing a partner with a deep, sustainable grinding capability is a strategic move to de-risk your most critical projects.

Conclusion: Your Path from Engineer to Strategic Decision-Maker

Making the right choice between milling and grinding is more than a technical detail; it’s a strategic decision that impacts cost, performance, and reliability. By understanding the clear, data-driven limits of milling, you can confidently identify the three red-line triggers—part function, surface integrity, and post-heat-treatment requirements—that make precision grinding necessary.

But your role doesn’t stop at making the technical call. By quantifying the business case and considering the total cost of quality, you evolve from an engineer executing a design to a strategic partner driving the success of the project.

At our core, we believe the best manufacturing partnerships are collaborative. We once worked with an aerospace client on a complex landing gear component. Instead of just quoting their initial design, which had extensive and costly grinding requirements, we initiated a Design for Manufacturability (DFM) review.

By working together, we identified areas where grinding was non-essential and optimized the design. The result? A 25% reduction in manufacturing cost and a three-week shorter lead time, all without sacrificing a single ounce of performance.

If your next project demands precision that pushes the limits, let’s have a conversation. The Zenithin’s team can help you navigate these critical decisions and ensure your design is not only successful but also cost-effective and robust.