Abrasive & Bead Blasting Service

Achieve a uniform, non-reflective matte finish or perfectly prepare your parts for subsequent surface treatments like anodizing or painting.

- Uniform Matte Finish

- Perfect Surface Prep

- Deburring & Cleaning

Sandblasting Solutions for Every Application

Achieving the perfect surface finish requires precise control over every variable. We meticulously tailor our process based on the abrasive media, the part’s material, and specific technical parameters to deliver consistent, high-quality results. Explore the details of our capabilities below.

Surface Prep for Coatings

Creates an ideal micro-etched surface profile to dramatically increase adhesion for paint, powder coating, and anodizing.

Aesthetic Matte Finishes

Delivers a clean, uniform, and non-reflective matte or satin look, perfect for high-end consumer products and architectural components.

Deburring & Part Cleaning

A cost-effective method for removing small burrs left from machining and cleaning surface contaminants like scale or light rust.

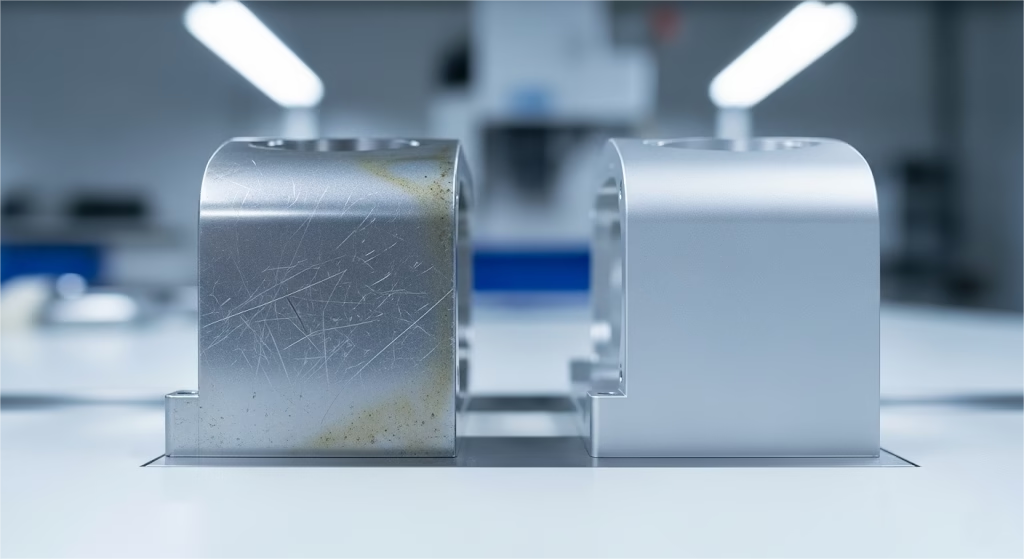

Restoration & Refinishing

Effectively strips old paint, coatings, and corrosion to restore parts to their original bare metal state, ready for refinishing.

Our Sandblasting Capabilities

Achieving the perfect surface finish requires precise control over every variable. We meticulously tailor our process based on the abrasive media, the part’s material, and specific technical parameters to deliver consistent, high-quality results.

The choice of abrasive media is critical to achieving the desired outcome. We select the optimal media based on your material, the required finish, and the application’s end goal. Our primary options include:

Glass Beads:

A fine, spherical media that is chemically inert and gentle on the part’s surface. It’s ideal for creating a smooth, bright, satin finish, often used for cosmetic parts, cleaning delicate components, and finishing materials like aluminum and stainless steel.

Aluminum Oxide:

A hard, angular abrasive that is highly effective for creating a uniform, non-glare matte texture. Its aggressive cutting action is excellent for removing heavy scale or rust and creating a deep profile for superior paint and coating adhesion.

Steel Grit:

A very aggressive, hard angular media used for high-impact cleaning and surface profiling on robust ferrous materials like carbon steel. Ideal for preparing structural components or removing heavy, stubborn contaminants.

Plastic Media:

A soft, gentle abrasive used for stripping paint or cleaning delicate substrates like aluminum, composites, or thin plastics without damaging or altering the underlying surface.

Our blasting processes are suitable for a wide range of materials. We have developed specific parameters for each material type to ensure we achieve the desired finish without compromising the part’s structural integrity.

Ferrous & Non-Ferrous Metals:

We expertly handle all common metals, from soft alloys like Aluminum and Brass to robust materials like Carbon Steel, Stainless Steel, and Titanium. Our process control ensures consistent results across all metallic substrates.

Engineering Plastics:

We have the expertise to perform gentle bead blasting on robust engineering plastics such as PEEK, Delrin (POM), and Nylon. This is ideal for achieving a uniform matte texture or for surface preparation before bonding.

Composites:

Our controlled blasting techniques can be used to prepare composite surfaces like Carbon Fiber or Fiberglass for painting or bonding, creating an ideal surface for adhesion without damaging the sensitive fibers.

Our process is tightly controlled to deliver consistent, predictable results for every part in your order. We focus on key specifications to meet your requirements.

Part Size & Handling:

Our blasting cabinets can accommodate parts up to 1000 x 800 x 500 mm. We utilize custom fixtures to protect critical features and handle delicate or complex components safely.

Finish Control & Consistency:

We precisely control key variables like air pressure, nozzle distance, and blasting duration. This allows us to achieve a wide range of finishes, from a fine satin to a coarse matte, and ensure a consistent surface profile (Ra) across your entire batch.

Post-Process Cleanliness:

Following blasting, all components undergo a thorough multi-stage cleaning and inspection process. This removes all residual media and dust, ensuring your parts are pristine and ready for the next stage of your production, be it coating, assembly, or final packaging.

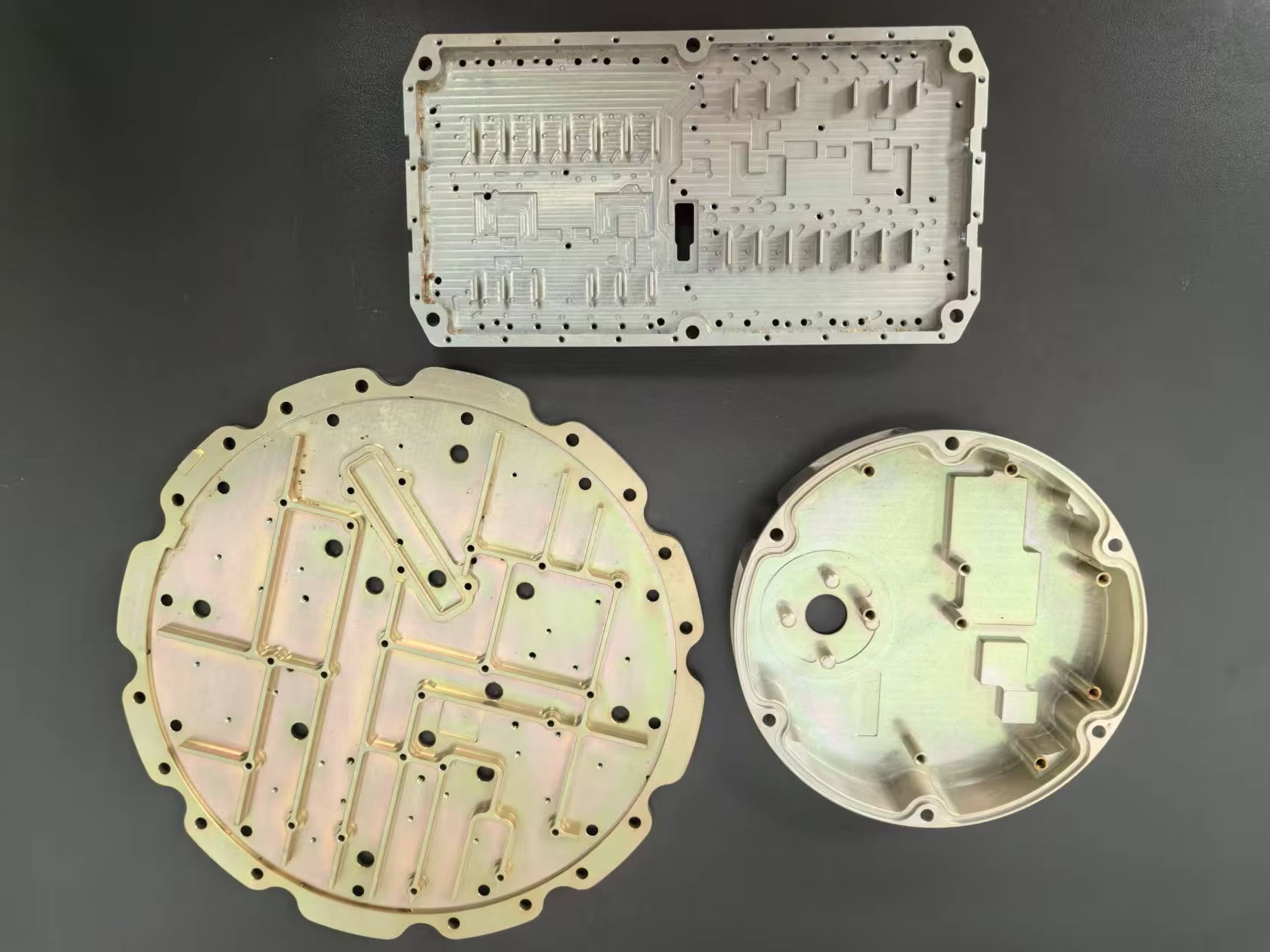

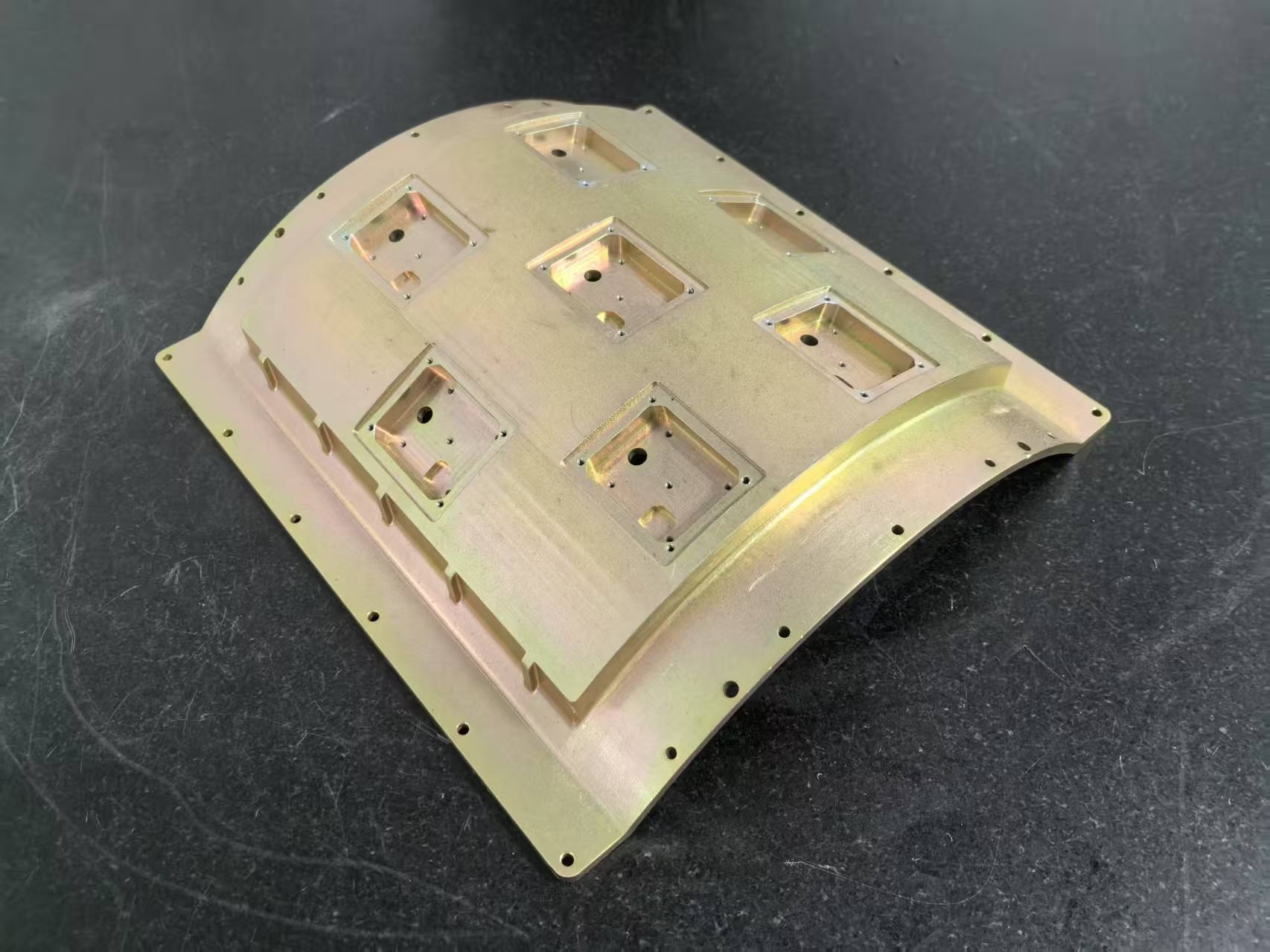

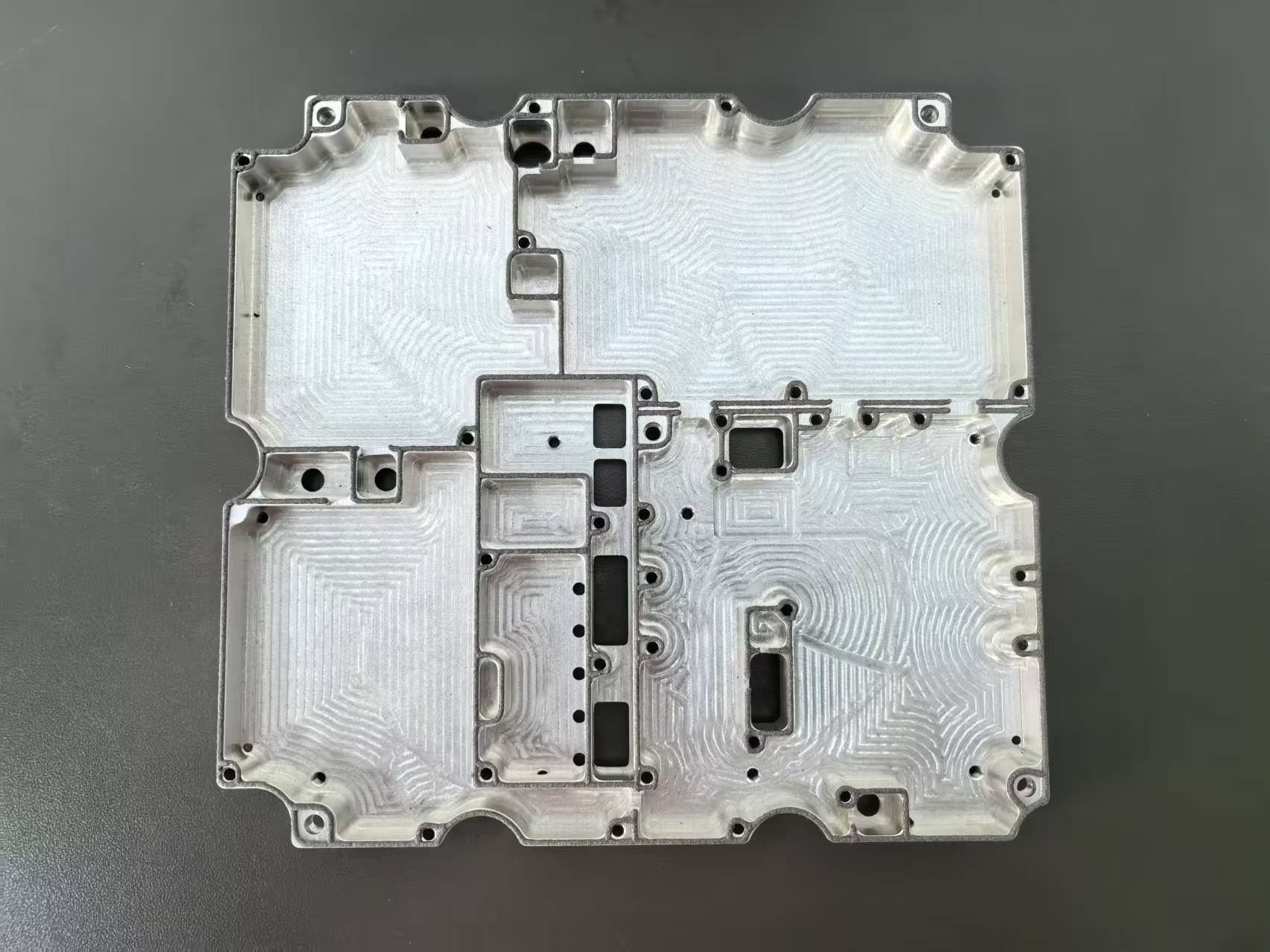

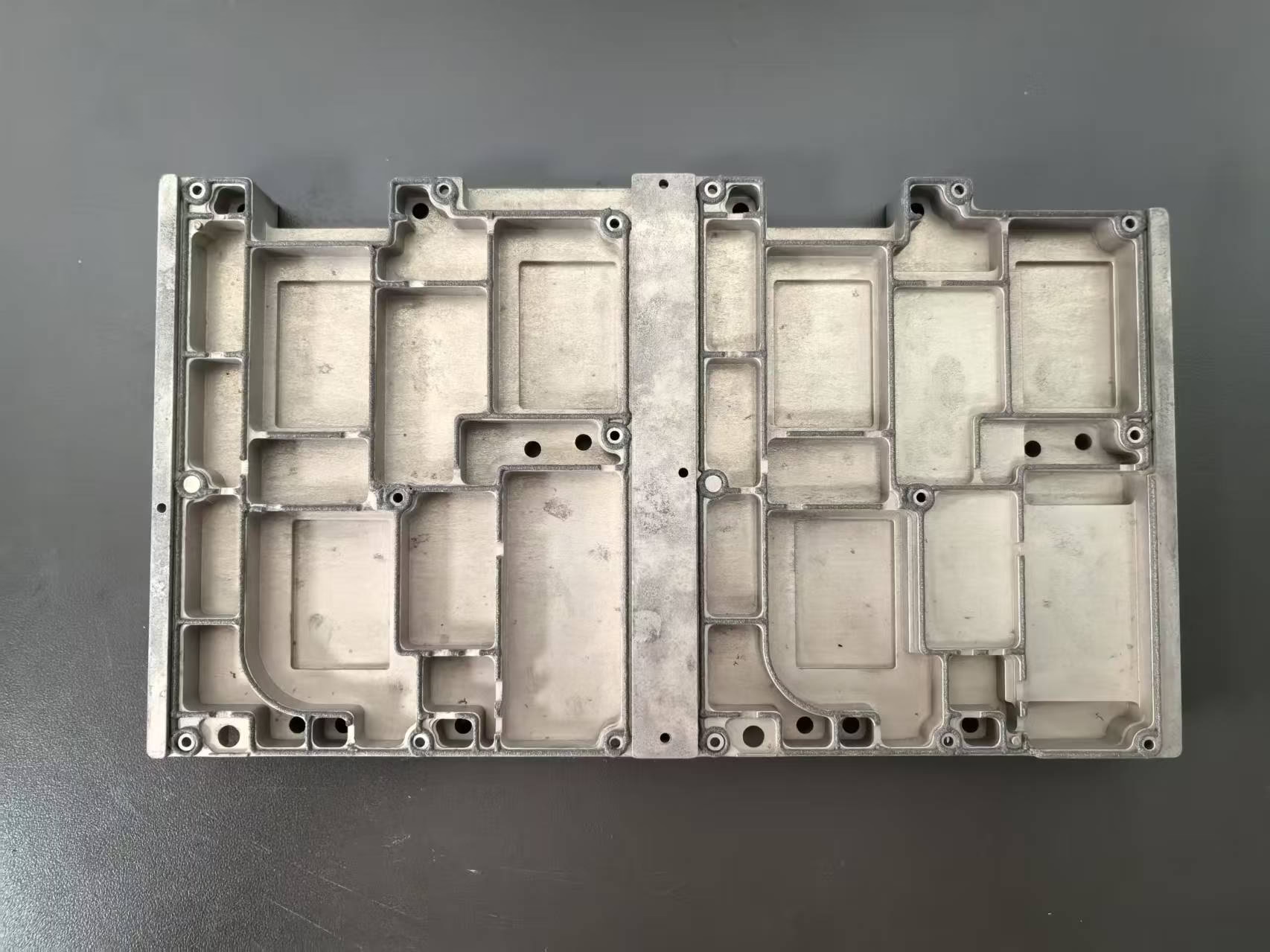

Our Blasting Portfolio

Our blasting process delivers consistent, high-quality results. Explore our gallery to see real-world examples of parts we have processed.

Ready for a Flawless Finish?

Let us apply the same attention to detail and commitment to quality to your components. Upload your design files to discuss your finishing requirements with our experts.

Key Support for Your Surface Finishing Project

Beyond a high-quality finish, we provide value-added services to ensure your parts are processed correctly and efficiently, saving you time and preventing costly errors.

Your Blasting Questions, Answered

Find quick answers to common technical questions about our abrasive and bead blasting services. If your question isn’t listed, our team is always ready to help.

Sandblasting typically uses harder, angular abrasives like aluminum oxide for aggressive cleaning and creating a matte texture. Bead blasting uses finer, spherical media like glass beads for a much smoother, satin finish with minimal material removal.

When performed by experts, no. We carefully select the correct media and pressure for your material to achieve the desired finish without affecting critical tolerances. For ultra-precise features, we can apply selective masking.

A fine-grit abrasive blast is an excellent preparation for anodizing. It creates a clean, uniform matte surface that results in a very high-quality, non-reflective anodized finish.

Most metals are suitable for blasting. For plastics, we can perform gentle bead blasting on robust engineering plastics like PEEK and Delrin (POM). We do not recommend it for softer plastics like ABS or Polycarbonate as it can damage the surface.

The final Ra value depends heavily on the original surface and the media used. A gentle bead blast on a smooth aluminum part can result in a finish around Ra 1.6 μm to 3.2 μm. A more aggressive blast will result in a higher Ra value.

Yes, absolutely. Every part undergoes a thorough post-blast cleaning process to remove all residual media and dust. Your parts will arrive pristine and ready for the next stage, whether it's assembly, coating, or packaging.

Ready to Achieve the Perfect Surface?

Whether you need a standalone blasting service or as part of a complete manufacturing process, our team is ready to help. Let’s discuss your surface finish requirements.

Let's Discuss Your Project

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.

.avif)

-scaled.avif)