Confidently decide between PEEK and aluminum for your high-tech components. This guide provides a clear, data-driven framework, helping you avoid costly material selection mistakes and optimize your design for performance in the medical, aerospace, or semiconductor fields.

Choose PEEK over aluminum when your application demands superior chemical resistance, biocompatibility, electrical insulation, or high-temperature performance where aluminum would fail. While aluminum offers higher raw strength, PEEK provides a comparable strength-to-weight ratio with critical functional advantages.

Now that you have the short answer, read on to explore the detailed decision framework, see real-world case studies, and understand the total cost of ownership beyond just the material price.

A Quantitative Comparison of PEEK and Aluminum

When comparing materials—a topic we cover broadly in our plastic vs. metal machining guide—the numbers matter.

While PEEK and Aluminum are ideal for functional engineering parts, other applications focused on aesthetics, like custom brand mascots or figurines, rely on different materials like Polyresin.

For this specific comparison, let’s get straight to the facts to see where PEEK and aluminum shine.

Physical and Mechanical Properties

At first glance, aluminum seems to have a clear advantage in raw strength. A common grade like 6061-T6 aluminum has a tensile strength of around 240-310 MPa, which is two to three times higher than PEEK’s 90-100 MPa.

However, this is only half the story. The real magic of PEEK lies in its remarkably low density.

- Density: PEEK comes in at ~1.30 g/cm³, while 6061-T6 aluminum is ~2.70 g/cm³.

- Weight Savings: This means that for a part of the exact same size, switching to PEEK can result in a weight reduction of nearly 50%.

While aluminum is stronger in absolute terms, PEEK’s impressive strength-to-weight ratio makes it a powerful contender, especially in aerospace and medical applications where every gram counts.

Key Functional Properties

Beyond strength and weight, certain functional properties create clear dividing lines between these two materials.

If your application requires any of the following, PEEK isn’t just an alternative; it’s often the only viable choice.

- Electrical Insulation: PEEK is an exceptional electrical insulator with a dielectric strength of 19 kV/mm. Aluminum, being a metal, is a conductor. For semiconductor equipment or electronic components where electrical insulation is critical, PEEK provides a level of safety and performance that aluminum simply cannot match.

- Biocompatibility: PEEK is certified to meet ISO 10993 and USP Class VI standards, making it safe for long-term implantation in the human body. This has made it a go-to material for spinal cages, cranial plates, and other medical devices. Aluminum is not biocompatible and cannot be used in these applications.

- Chemical and Thermal Resistance: PEEK demonstrates outstanding resistance to a wide range of chemicals, including acids, bases, and organic solvents, even at high temperatures. It can be continuously used at temperatures up to 250°C (482°F) while retaining its mechanical properties. Aluminum, in contrast, is susceptible to corrosion from strong acids and bases and its strength diminishes significantly at temperatures above 150°C.

As Dr. John W. Stannard, a marketing leader at Victrex plc, puts it, engineers must think in terms of ‘functionality’ rather than just ‘material.’ He explains, “If your part needs to be strong, lightweight, and also a good insulator, a polymer like PEEK becomes the only viable option. The material choice is driven by the part’s performance requirements, not a simple price per pound comparison.”

This highlights that the decision often comes down to the unique functional demands of your project.

| Property | PEEK | Aluminum (6061-T6) |

|---|---|---|

| Electrical Insulation | Excellent | None (Conductive) |

| Biocompatibility | Excellent (Implant Grade) | Poor |

| Chemical Resistance | Excellent | Poor (vs. strong acids/bases) |

| Max Use Temp. | 250°C (482°F) | ~150°C (302°F) |

A Decision Guide for Engineers: The Three-Step PEEK Selection Process

Knowing the data is one thing, but how do you apply it to your specific project?

Instead of getting lost in datasheets, use this simple three-step framework to guide your decision-making process.

Step 1: Redefine Your Core Project Need

First, move beyond the default question of “Is it strong enough?” and ask, “What is the single most critical function this component must perform?”

Often, the primary requirement isn’t structural strength alone. Is your project’s success contingent on:

- Absolute Electrical Insulation? For components in semiconductor manufacturing or high-voltage electronics, this is non-negotiable.

- Biocompatibility for Medical Use? If the part will be implanted or have prolonged contact with the human body, this is your primary filter.

- Survival in a Corrosive Chemical Environment? For industrial or lab equipment, material resilience is key.

If your answer is yes to any of these, PEEK immediately becomes a front-runner, not because of its strength, but because of its unique functional properties that aluminum cannot replicate.

Step 2: Evaluate the Application Environment

Next, consider the world your component will live in. Aluminum is a robust material for standard conditions, but extreme environments can quickly expose its weaknesses.

Ask yourself if the part will be exposed to:

- High Temperatures: Will it operate continuously above 150°C?

- High Vacuum: Is low outgassing critical, like in a semiconductor chamber?

- Sterilization Cycles: Does it need to withstand repeated autoclaving (steam sterilization)?

These are all scenarios where PEEK excels. However, it’s also important to be aware of PEEK’s higher Coefficient of Thermal Expansion (CTE), which is roughly double that of aluminum (~50 ppm/°C for PEEK vs. ~24 ppm/°C for aluminum).

In designs with tight tolerances that experience significant temperature swings, this dimensional change must be accounted for during the design phase to avoid issues.

Step 3: Calculate the Total Cost of Ownership

Finally, it’s crucial to look beyond the initial material cost. While PEEK’s raw material price is significantly higher than aluminum’s, the total cost of the final, installed part can often be surprisingly competitive.

Think about the “hidden” costs associated with an aluminum part:

- Secondary Processing: Does it require anodizing or a special coating for corrosion resistance or insulation? These are extra steps, adding time and expense.

- Assembly Complexity: Could a single, complex PEEK part replace an assembly of multiple aluminum pieces, fasteners, and insulators? This reduces part count, simplifies assembly, and lowers labor costs.

- Lifecycle Costs: A PEEK component that lasts twice as long as an aluminum one in a corrosive environment eliminates the cost of replacement parts and, more importantly, costly equipment downtime.

By analyzing the full picture—from raw material to assembly and long-term reliability—you can make a much more accurate and defensible cost assessment.

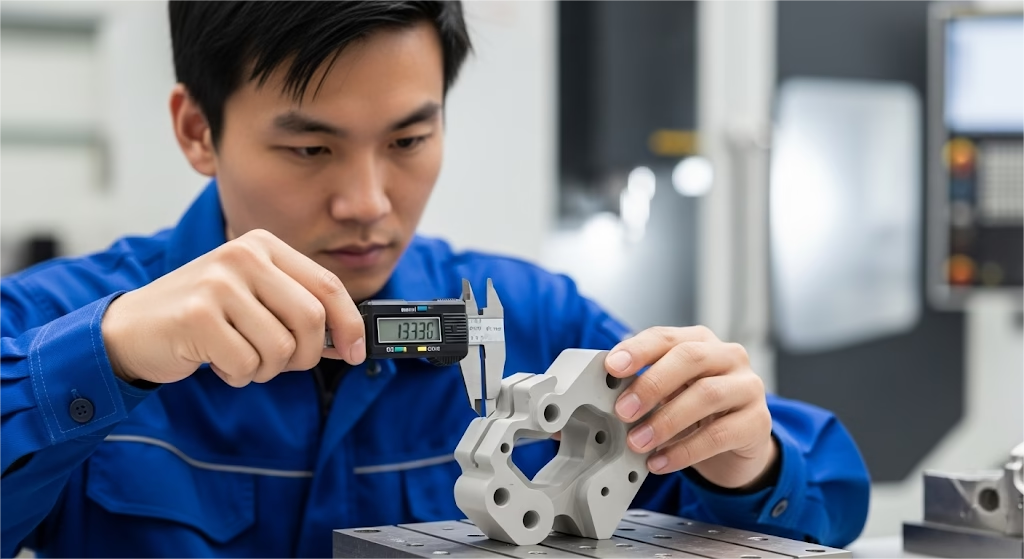

Master Your PEEK and Plastic Parts with Precision Machining

When your design demands the unique properties of high-performance plastics like PEEK, standard machining won’t do. Our specialized CNC Milling Services ensure your components meet the tightest tolerances and functional requirements.

Addressing Cost and Machining Concerns

Let’s tackle the two biggest elephants in the room when it comes to PEEK: its high cost and reputation for being difficult to machine.

It’s true that PEEK requires a different approach than aluminum, but understanding why is the key to unlocking its full potential.

The Machining Philosophy: Heat Control vs. High-Speed Cutting

Why is machining PEEK more expensive than aluminum? It comes down to a fundamental difference in manufacturing philosophy.

Machining aluminum is all about speed and efficiency—high spindle speeds, aggressive feed rates, and rapid material removal. It’s a process optimized for speed.

PEEK, on the other hand, demands a more deliberate approach. The core challenge in machining PEEK is managing heat and internal stress. Because it’s a polymer, excessive heat generated during cutting can cause localized melting, create micro-cracks, or induce stress that leads to warping after the part is finished.

These are subtle defects that might not be visible upon inspection but could cause catastrophic failure under load or in extreme temperatures.

This is why you can’t simply hand a PEEK job to any machine shop that specializes in aluminum. A skilled PEEK machinist uses specialized tooling, slower feed rates, and specific cooling techniques to preserve its exceptional properties.

Turning High Cost into a Competitive Advantage

So, how do you justify the higher upfront cost of a PEEK component to your project manager? You do it by shifting the conversation from material cost to total system cost and risk mitigation.

The initial investment in a precisely machined PEEK part is often an insurance policy against much larger costs down the line. Consider the true cost of failure for an aluminum part in a critical application:

- The cost of equipment downtime during replacement.

- The cost of product recalls or warranty claims.

- The potential damage to your company’s reputation.

By choosing PEEK for the right application, you are investing in reliability. This investment not only ensures the performance of your product but also protects your project’s budget from unforeseen expenses.

From Theory to Reality: A Case Study in Semiconductor Manufacturing

Sometimes, the true value of a material isn’t revealed in a datasheet, but in solving a real-world problem that has a team of talented engineers completely stuck.

We recently worked with a leading semiconductor equipment manufacturer facing this kind of challenge. Their team had designed a critical fixture for handling silicon wafers, and following standard practice, they specified anodized aluminum.

However, during prototype testing, two “invisible” but critical failures emerged.

The Challenge: Hidden Defects in a High-Stakes Environment

The aluminum part suffered from two key issues:

- Electrostatic Discharge (ESD) Risk: The anodized coating wasn’t a perfect insulator, creating a risk of destroying sensitive microchips.

- Vacuum Contamination: The fixture was exhibiting low-level outgassing in the vacuum chamber, compromising wafer integrity and reducing production yield.

The team was in a bind. The aluminum part, despite its strengths, had become the project’s biggest liability.

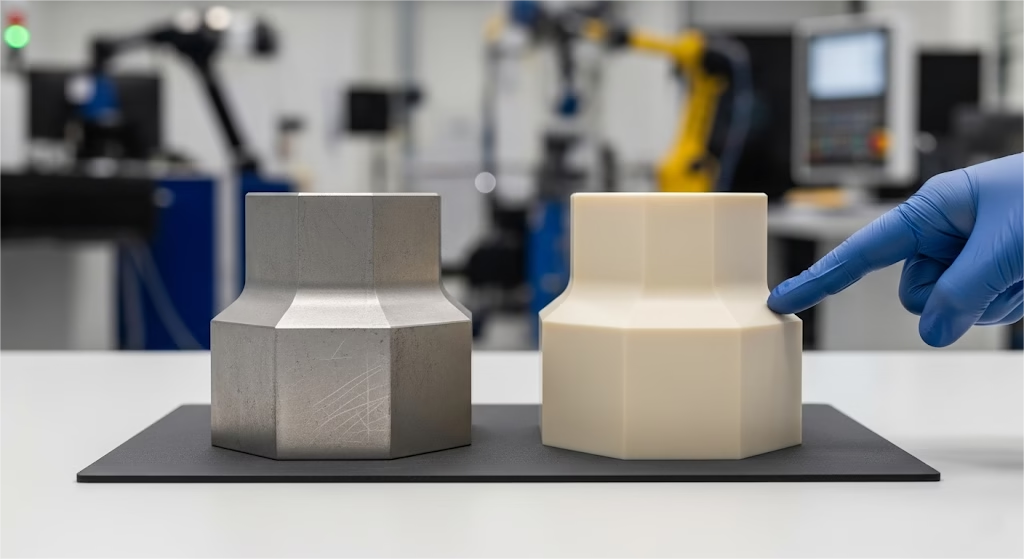

The Solution: More Than Just a Material Swap

We proposed PEEK as the ideal solution due to its inherent insulative properties and low outgassing characteristics. However, this wasn’t a simple “drop-in replacement.”

A very thin wall in the original design, stable in aluminum, caused microscopic deformation in PEEK due to internal material stresses. This is a classic “trap” when moving from metals to polymers. Instead of delivering a flawed part, we collaborated with their design team.

By slightly increasing the wall’s thickness—a minor Design for Manufacturability (DFM) tweak that didn’t affect function—we created a component that was both dimensionally perfect and incredibly stable.

The Result: A Definitive Success

The final PEEK fixture was a complete success. It entirely eliminated the risks of both electrostatic discharge and vacuum contamination, leading to a measurable improvement in wafer yield.

This experience proved that choosing PEEK isn’t about saving money on a part; it’s about investing in a solution that works.

Your Final Decision: It’s More Than a Material

Ultimately, the choice between PEEK and aluminum isn’t just a line item on a bill of materials. It’s a strategic engineering decision.

While aluminum remains an excellent choice for a vast range of applications, PEEK emerges as the definitive solution when you’re pushing the boundaries of performance.

The final answer isn’t simply “PEEK” or “aluminum.” It’s finding a manufacturing partner who understands the deep science behind both materials. The right partner helps you leverage the unique strengths of a high-performance polymer to create a component that is not just functional, but optimal.

If your project is facing challenges with electrical insulation, biocompatibility, chemical resistance, or extreme temperatures, it may be time to look beyond traditional metals. Making the right call on when to choose PEEK over aluminum can be the defining factor in your project’s success.

Ready to Machine Your High-Performance Parts?

You’ve done the research. Now let our experts machine your PEEK and other advanced material components with the precision your project demands.