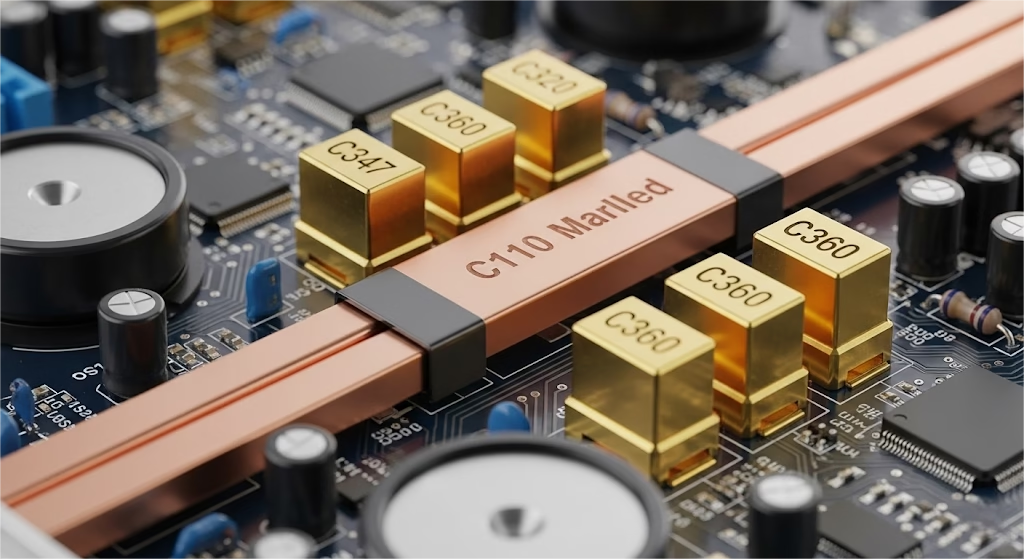

Are you trying to decide on the right material for a critical electrical or thermal component? You’re likely weighing the superior performance of C110 copper against the lower machining cost of C360 brass. You know the datasheet specs, but you also know that the real-world decision for machining copper vs. brass is far more complex than a few numbers on a chart.

This choice impacts everything from your project’s budget and timeline to the final product’s reliability. Making the wrong call can lead to costly redesigns or, worse, field failures.

But you’re in the right place. Before we dive deep, here’s a quick-glance table that summarizes the essential trade-offs you’re facing.

| Property | C110 ETP Copper | C360 Free-Cutting Brass |

|---|---|---|

| Machinability Rating | 20% | 100% (The Benchmark) |

| Electrical Conductivity | 101% IACS | 26% IACS |

| Thermal Conductivity | 388 W/m·K | 115 W/m·K |

These numbers tell a clear story: copper offers elite thermal and electrical performance, while brass provides unmatched manufacturing efficiency.

This guide goes beyond the data. We’ll provide a complete decision framework, exploring the nuances of Design for Manufacturability (DFM), calculating the true Total Cost of Ownership (TCO), and sharing real-world lessons learned from projects just like yours.

By the end, you’ll be equipped to confidently select the right material for your application.

Part 1: The Core Trade-Offs: Performance, Machinability, and Cost

When you’re evaluating materials, you’re constantly balancing three key factors. But beneath the surface of the datasheet, hidden variables can completely change the equation.

The Performance Gap: More Than Just Numbers

In high-stakes applications, performance isn’t just a number—it’s about reliability. Electrically, C110 copper is the undisputed champion with an IACS rating of 101%. In contrast, C360 brass comes in at just 26%.

According to Ohm’s Law (P=I2R), this difference is critical. In high-current parts like busbars, the lower resistance of copper means significantly less heat generation and power loss.

The story is similar for thermal management. With a thermal conductivity of 388 W/m·K, copper is incredibly efficient at moving heat. Brass, at 115 W/m·K, is a distant second.

This is why experts in thermal management, like the engineers at Aavid, Thermal Division of Boyd Corporation, often recommend using copper strategically—only where it’s absolutely necessary. A common and intelligent design compromise is to use a copper base in a heat sink for rapid heat spreading from the source, bonded to more cost-effective aluminum fins for dissipation.

However, a critical insight that datasheets will never show you is that not all C110 copper is created equal. The material’s origin, rolling process, and internal stresses can dramatically affect its real-world performance.

A lower-cost copper from an unvetted supplier might meet the basic chemical spec, but it could have impurities or inconsistencies that lead to unexpected warping during machining or performance variations from batch to batch.

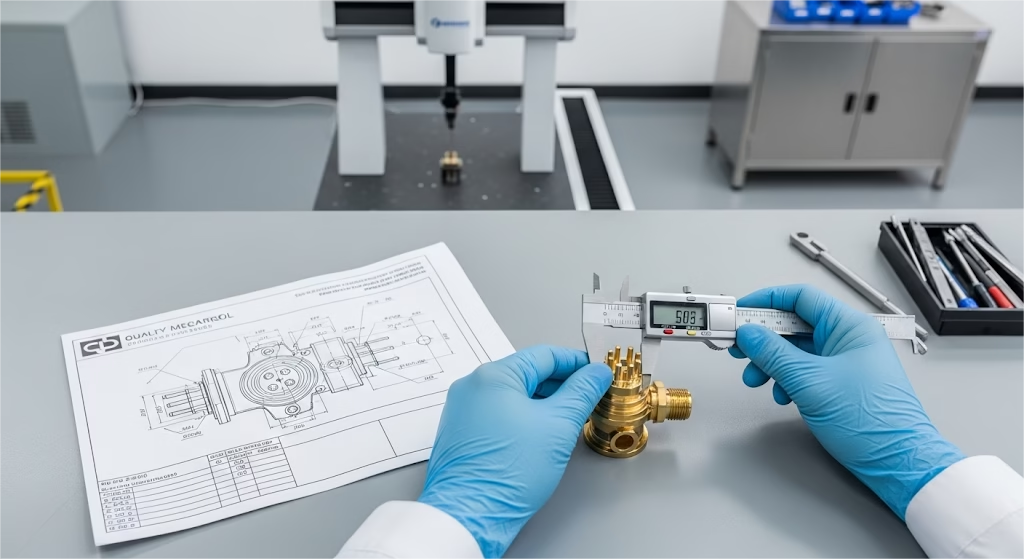

For critical applications, always partner with a machine shop that provides a Material Traceability Certificate to ensure the integrity of your raw material from the start.

The Machinability Divide: The Reality on the Shop Floor

So, if copper’s performance is so dominant, why is this even a discussion? It comes down to one word: machinability.

C360 brass is the benchmark for a reason, with a machinability rating of 100. As the Copper Development Association (CDA) explains, the small amount of lead in its composition acts as a microscopic chip breaker and a built-in lubricant. The result is small, manageable chips and smooth, fast cutting.

Machining pure copper, rated at just 20, is an entirely different experience. It’s soft and “gummy,” leading to long, stringy chips and a tendency to weld itself to the cutting tool (built-up edge).

Achieving precision in such a material requires more than just the right tool; it demands a highly rigid machine and a carefully engineered process from your high-precision manufacturing partner.

The Cost Iceberg: Uncovering the Hidden Expenses

It’s easy to look at the per-pound price and conclude that brass is cheaper. But that’s just the tip of the iceberg. The true cost of a machined part is a combination of factors:

Total Cost = (Material Cost) + (Machining Time × Machine Rate) + (Tooling Cost) + (Risk Cost)

Machining copper can take up to five times longer than brass. That initial material saving evaporates quickly in machine time. Furthermore, you must consider the “risk cost,” especially regarding environmental regulations.

The lead in C360 brass makes it a risky choice for new products targeting global markets with rules like the EU’s RoHS directive. Switching to a “lead-free” brass isn’t a simple fix either, as their machinability is often significantly lower.

This “brass trap” can lead to unexpected production challenges and costs if not planned for from the project’s inception.

Part 2: Breaking the Deadlock: The “Third Way” Beyond a Binary Choice

So, you’re faced with a tough choice: the stellar performance of copper that’s difficult to machine, or the easy-to-machine brass that compromises on performance. But what if you didn’t have to pick a side?

Meet C145 Tellurium Copper. This alloy is a game-changer for many applications, offering a remarkable balance:

-

Electrical Conductivity: Over 90% IACS

-

Machinability Rating: 85%

With tellurium copper, you get nearly all the conductive performance of pure copper, but with the manufacturing ease approaching that of free-cutting brass.

We saw this firsthand with a startup developing new high-frequency RF connectors. They initially specified pure C101 copper for its ultimate performance, but the complex parts led to a 50% scrap rate and runaway costs.

After a discussion, we found that their design’s actual minimum requirement was 90% IACS, not 101%.

We switched them to C145 Tellurium Copper. The result? The part performed flawlessly, the scrap rate dropped to nearly zero, and the final part cost was reduced by 60%.

The lesson is powerful: The best material isn’t always the one with the highest performance number, but the one that most intelligently meets the total needs of the application.

Get a Quote for Your Copper or Brass Parts

Have a complex design in copper, brass, or tellurium copper? Our expertise in 5-axis CNC machining ensures we can meet your tightest tolerances. Upload your drawing to get a quote from our engineering team.

Part 3: From Print to Part: Designing for Reality

A great design on paper can quickly become a manufacturing nightmare. Design for Manufacturability (DFM) is about making your design robust for the real world.

A crucial insight to remember here is that machining is not just shaping a part; it is a performance variable. The process itself affects the final function.

DFM for C110 Copper: Taming a Soft Material

When designing with C110 copper, your main goal is to accommodate its soft and “gummy” nature.

-

Be Generous with Radii: Sharp internal corners create stress and can cause material to build up on the tool.

-

Avoid Thin Walls: Copper is not rigid and can deflect easily, making it hard to hold tight tolerances on thin features. Our CNC wall thickness guide can help you avoid costly failures.

-

Specify Functional Surfaces: Don’t just dimension a part; think about its function. For a high-frequency component, the surface finish (Ra) can impact signal loss due to the “skin effect.” For thermal parts, a smoother finish means better contact and heat transfer. Specify these critical surface requirements on your drawing.

-

Rethink Your Threads: We once had a client whose beautiful copper cold plates were failing during assembly because the soft M3 threads were stripping. The solution was to switch from cutting taps to forming taps, which create much stronger threads through cold working. It’s a process detail that saves the final product.

DFM for C360 Brass: Unleashing a Machining Champion

Designing for C360 brass is much more freeing. Its excellent machinability means you can embrace complexity, specify tighter tolerances, and achieve a superior surface finish directly off the machine.

| Consideration | C110 Copper (Soft & Gummy) | C360 Brass (Hard & Brittle) |

|---|---|---|

| Internal Corners | Use larger radii | Can accommodate sharp corners |

| Wall Thickness | Avoid thin walls to prevent deflection | Excellent for thin-walled features |

| Threads | Use forming taps for strength | Standard cutting taps are effective |

| Complexity | Simpler geometries are preferred | Ideal for intricate, complex designs |

Part 4: Making the Final Call: Your Project Decision Checklist

You’ve absorbed a lot of information. Now it’s time to apply it to your specific project. Walk through the following checklist to clarify your needs and illuminate the most logical path forward.

-

What is your absolute minimum required conductivity? Be specific with your numbers (%IACS, W/m·K).

-

How geometrically complex is your part? More complexity favors more machinable materials.

-

What are your target markets? Consider environmental regulations like RoHS from day one.

-

What are the assembly and service conditions? Think about torque, temperature, and potential corrosion.

-

Is your priority a low upfront part cost or a low total lifetime cost? Balance the immediate budget against long-term reliability and potential failure costs. This guide on the true cost of CNC parts can help you justify your decisions.

Conclusion: Making the Right Choice for Your Application

Choosing between copper and brass isn’t about crowning a single “best” material. The optimal choice is revealed by a deep understanding of your specific application’s demands.

It’s a careful balance between the electrical and thermal performance you need, the manufacturing cost you can afford, and the long-term reliability your product requires.

The best material is the one that most intelligently meets the total needs of your project. This guide on machining copper vs. brass aims to empower you to make that choice with confidence.

Ready to Machine Your Custom Parts?

You’ve done the research. Now let our experts turn your design into a reality with the precision your project deserves.

References & Notes

[1] Machinability Ratings: The machinability ratings for copper alloys are standardized by the Copper Development Association (CDA). C360 Free-Cutting Brass is set as the baseline standard at 100%.

[2] IACS: This stands for the International Annealed Copper Standard. It is a unit of electrical conductivity for metals, where the conductivity of a commercially pure, annealed copper sample from 1913 is defined as 100% IACS.