Tired of fighting vibration, deflection, and high scrap rates when machining long, slender parts? This is the definitive guide to eliminating those problems. You’ll learn the proven manufacturing process that guarantees precision and turns your most challenging designs into reality.

To machine long, slender parts with high precision, use a Sliding Headstock Lathe, also known as a Swiss-type machine. This method uses a guide bushing to provide rigid support to the workpiece right at the point of the cut. This design virtually eliminates part deflection, allowing for extremely tight tolerances and superior surface finishes on components with a high length-to-diameter ratio.

Now that you know the best method, it’s time to dive deeper. In the full article, we’ll break down the physics behind why this works and show you how to choose the right manufacturing partner for your precision machining needs.

The Physics of Part Failure

Your concern is rooted in fundamental physics. The primary challenge in machining any component with a high length-to-diameter (L/D) ratio is managing deflection. On a conventional lathe, where the part is held at one end, a rule of thumb states that machining issues begin when the L/D ratio exceeds 3:1. Once you pass 10:1, achieving precision without extra, often cumbersome, support like a tailstock or follow rest becomes nearly impossible.

The reason for this is captured in the cantilever beam deflection formula, which an engineer will appreciate: δ = FL³/3EI

Here, the deflection (δ) is the amount the part bends under the cutting force (F). But the most critical variable is L—the unsupported length of the part.

Notice that deflection increases with the cube of this length (L³). This means doubling the unsupported length doesn’t just double the deflection; it increases it by a catastrophic eight times.

This exponential increase is why traditional methods inevitably fail to hold tight tolerances on long, slender parts.

The Superior Method: Sliding Headstock Machining

To overcome this physical limitation, you need to change the equation itself. This is precisely what a sliding headstock lathe, commonly known as a Swiss-type machine, accomplishes.

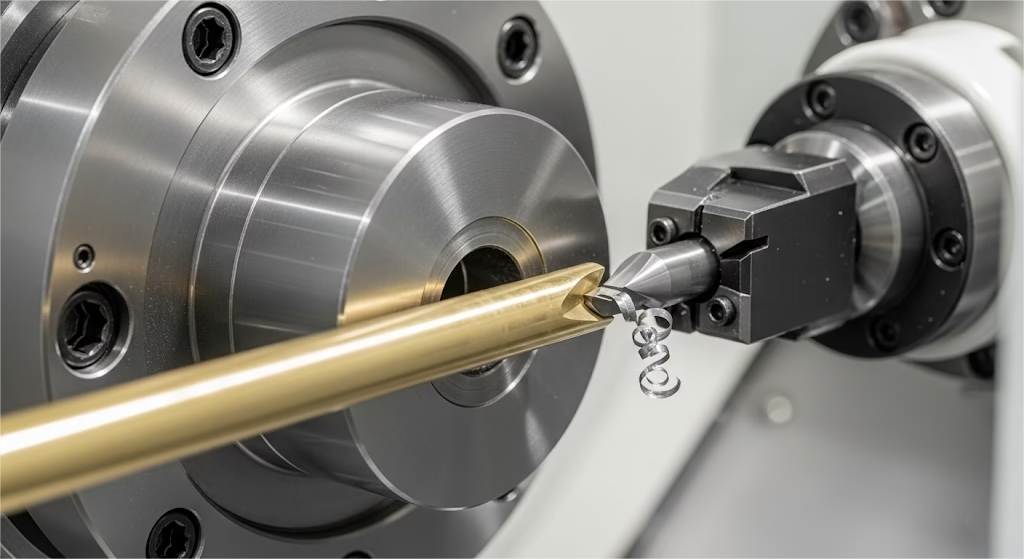

Imagine a process where the workpiece, instead of being held stationary, is advanced through a solid guide bushing. The cutting tools then engage the material right at the point where it emerges from this bushing. This design is the core of Swiss-type machining. The sliding headstock feeds the bar stock through the guide bushing, while the tools remain stationary near the point of support.

This ingeniously simple concept completely alters the physics of the cut. The critical variable L—the unsupported length—is reduced to a minimal, constant distance between the tool and the guide bushing. By keeping L incredibly small, the catastrophic effect of the L³ multiplier is virtually eliminated.

This allows the machine to turn parts with L/D ratios of 20:1, 30:1, or even higher, all while maintaining exceptional accuracy and surface finish.

It’s no longer a battle against deflection; it’s a system designed to prevent it from ever becoming a factor.

Proof in Performance and Practice

The theoretical advantage of sliding headstock machining is confirmed by its real-world performance. This method consistently produces parts with dimensional tolerances as tight as ±0.005 mm (5 microns) and surface finishes of Ra 0.4 μm or better, often eliminating the need for secondary grinding operations.

But what happens when this capability is overlooked?

Consider the real-world case of a medical device startup developing a novel surgical tool. The key component was a 180mm long, 2.5mm diameter stainless steel rod, a perfect example of the challenges faced with small, complex turned parts. To save on initial costs, they outsourced the job to a general CNC shop that offered a 40% lower piece price. The result was a near-disaster.

The project faced several issues:

- High Scrap Rate: The scrap rate was over 70% due to an inability to control straightness.

- Hidden Defects: Even “good” parts failed under load testing. Microscopic inspection revealed micro-fractures around a critical cross-hole, a direct result of uncontrolled vibration during machining.

- Project Delays: This “savings” delayed the project by a full quarter and jeopardized a round of funding.

This is why focusing solely on piece price is a dangerous trap. The true cost includes scrap rates, inspection time, assembly line failures, and project delays.

As Miles Free, a recognized expert from the Precision Machined Products Association (PMPA), emphasizes, “the guide bushing in a Swiss-type machine ‘provides rigid support right at the point of the cut, creating a stable, predictable environment.’ This ensures not only dimensional accuracy but also that the material’s structural integrity is never compromised—a non-negotiable factor for critical components.”

From Design to Partnership

Knowing the right technology is half the battle; applying it effectively is what ensures success. To help you move from theory to a finished, reliable part, here are practical steps for designing your component and selecting the right manufacturing partner.

Designing for Manufacturability (DFM)

To fully leverage the capabilities of Swiss-type machining, consider the factors in our guide to Design for Manufacturability (DFM) during your design phase:

- Tolerancing: Use a common datum for dimensioning to maintain accuracy along the part’s length. Specify geometric tolerances like straightness and concentricity, which are critical for slender parts.

- Features: Be mindful that features like keyways or flats along the outer diameter can interfere with the guide bushing. Whenever possible, locate these features at the ends of the part or consult with your manufacturing partner on the best approach.

Choosing the Right Partner

This may be the most critical step. A factory that simply has a Swiss-type machine is not the same as a factory that specializes in Swiss machining.

A true specialist possesses an entire ecosystem built around this technology: programmers with deep experience, quality control departments equipped with non-contact measurement systems, and a deep inventory of specialized tooling.

When vetting a potential partner, ask them what percentage of their business involves Swiss machining. If it’s not their primary focus, proceed with caution.

As described by John Zaya, a Senior Applications Engineer at Tsugami, a leading machine builder, “Customers often come to us after experiencing high scrap rates…The moment we demonstrate how a sliding headstock machine supports the workpiece with a guide bushing, the concept becomes clear.”

A true partner will not only have the right equipment but also the expertise to provide DFM feedback and help you optimize your design before a single chip is cut.

Don’t Face the Challenge Alone

When tasked with how to machine long, slender parts, the path to success is clear. It requires moving beyond traditional turning methods and embracing a technology specifically designed to overcome the fundamental physics of deflection. The solution lies in the precision and stability of sliding headstock machining.

This approach doesn’t just incrementally improve the process; it fundamentally changes the game, turning a high-risk challenge into a predictable, repeatable manufacturing operation.

However, the machine is only part of the equation. True success comes from collaborating with a partner who specializes in high-precision manufacturing and lives and breathes this technology. Don’t let your project’s fate be decided by a low initial bid from a non-specialist.

Instead, seek out a team of engineers who can act as an extension of your own, providing invaluable design feedback and process expertise.

If you have a challenging component on your screen, contact Zenithin’s team of specialists. Let’s work together to turn your design from a source of anxiety into a perfectly executed product, delivered with the certainty and reliability your project deserves.