Choosing a high-precision manufacturing partner is a high-stakes decision where a single mistake can lead to months of delays and significant cost overruns. This guide gives you a battle-tested framework to thoroughly vet suppliers. Use our checklist to avoid costly pitfalls and select a partner that becomes a true competitive advantage.

When selecting a high-precision manufacturing partner, critical evaluation criteria include their certified quality management system (e.g., ISO 9001, AS9100), advanced inspection capabilities (CMM), proactive Design for Manufacturability (DfM) feedback, relevant technology (5-axis CNC), and a proven record of supply chain stability.

This guide goes beyond a simple list of criteria. We provide a complete playbook that shows you how to identify a partner’s true capabilities, use a systematic process to reduce risk, and make a final, data-driven decision with confidence.

Before the Checklist: Understanding the Strategic Landscape

Before you dive into the specifics of equipment lists and certifications, it’s crucial to establish the right mindset. The goal isn’t just to find a supplier who can make your parts; it’s to find a strategic partner who can enhance your business, and that process begins with submitting a professional Request for Quotation.

From Vendor to Partner: A Critical Mindset Shift

A transactional vendor focuses on fulfilling purchase orders at the lowest possible price. A true strategic partner, however, contributes to your product’s success. They focus on the Total Value of Ownership (TVO), which includes not only the unit price but also the value they create through innovation and the costs they help you avoid through reliability.

This shift from a cost-focus to a value-focus is the first step in making a smarter decision, which is why following a CNC partner selection guide is so critical.

The “Factory DNA”: Identifying the Right Type of Partner

Not all manufacturers are created equal. They have different operational “DNA” that makes them suitable for different types of projects. Identifying this DNA upfront can prevent a fundamental mismatch down the line.

- The R&D / Prototype DNA: These shops are run by engineers who thrive on technical challenges. They are perfect for early-stage, complex projects that require intense collaboration and rapid iteration. However, they may struggle with cost control and process stability when it’s time to scale.

- The Mass Production / Efficiency DNA: These factories are masters of scale and efficiency. They excel at producing high volumes of mature products at a competitive cost. Their strength is process control and reliability, but they can be inflexible when faced with small orders or frequent design changes.

- The Integrated / Platform DNA: These are large, one-stop-shop contract manufacturers offering a full suite of services, from design to global logistics. They offer robust systems and risk mitigation but come with higher overhead and less personalized attention, which may not be suitable for smaller companies.

Before you use the following checklist, first ask yourself: “What DNA does my project need right now?” This single question will help you filter your options and focus your evaluation on partners who are truly a good fit.

The 10-Point Checklist for Vetting Your High-Precision Manufacturing Partner

With a clear strategic direction, you are now ready to use this 10-point checklist to evaluate potential partners. Each point is designed to help you look beyond the surface and assess the capabilities that truly matter.

1. Verifiable Quality Management System (QMS)

robust QMS is the bedrock of a reliable manufacturing operation. It’s the documented, repeatable system that ensures consistency and mitigates the risk of costly CNC machining defects, but it’s equally important to be aware of the common CNC supplier red flags that can undermine even the best systems.

Look for internationally recognized certifications like ISO 9001 for general quality, AS9100 for aerospace, or ISO 13485 for medical devices.

But a certificate on the wall isn’t enough. The real test is how deeply the quality mindset is embedded in their culture. The stakes are incredibly high; in the medical device sector alone, there were 32,336 recalls between 2012 and 2024, many stemming from manufacturing quality issues. Ask pointed questions like, “Can you walk me through your process for handling a non-conforming part?” Their answer will reveal more about their commitment to quality than any certificate could.

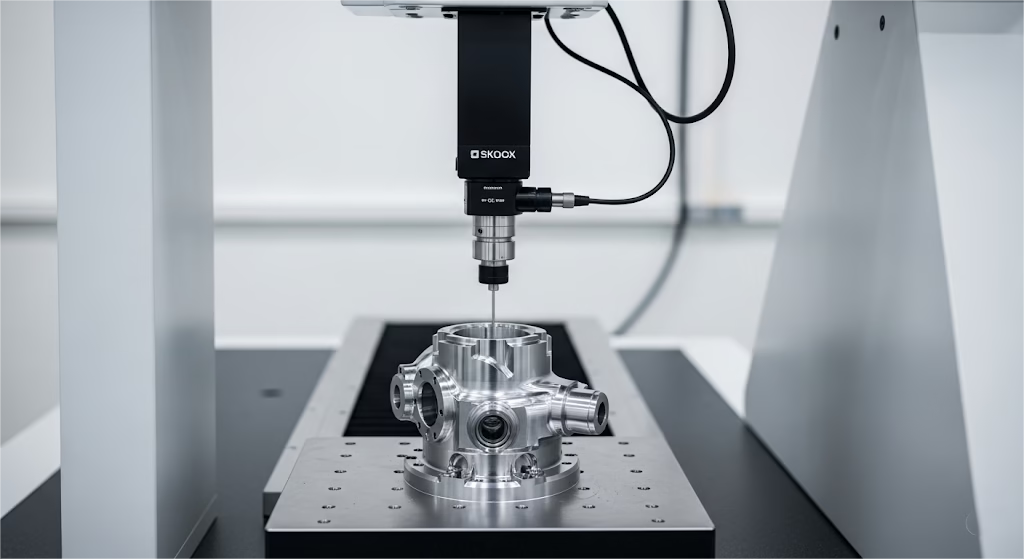

2. Advanced Inspection & Metrology Capabilities

In the world of high-precision manufacturing, if you can’t measure it, you can’t make it. Your partner must have the right equipment to verify that your parts meet spec, every single time. This goes beyond basic calipers and micrometers. Look for advanced metrology equipment like Coordinate Measuring Machines (CMMs) from reputable brands like Keyence or Zeiss.

A capable shop should be able to consistently hold tight tolerances of +/−0.001 inches (+/−0.025 mm) or better and produce parts with a superior surface finish, often as fine as Ra 0.2μm.

Ask for sample First Article Inspection (FAI) and CMM reports for parts with similar complexity to yours. If you’re a procurement manager, knowing how to read a CMM inspection report is a critical skill for this step. This demonstrates their ability to not only produce precision parts but also to document and prove it.

3. Proactive Design for Manufacturability (DfM) Feedback

This is often what separates a good supplier from a great partner. A great partner doesn’t just blindly follow your prints; they collaborate with you to improve them, using a precise language for communicating design intent to ensure the final part is both functional and cost-effective.

This practice, known as Design for Manufacturability (DfM), is about providing expert feedback to optimize your design for cost, quality, and efficiency before production begins.

As DfM pioneers like Geoffrey Boothroyd and Peter Dewhurst established, the majority of a product’s manufacturing cost is locked in during the early design stage. A partner who provides proactive DfM feedback is investing in your product’s success. They might suggest a small design tweak that dramatically improves manufacturability, lowers cost, and increases quality. Their silence on a complex design should be considered a red flag.

4. Relevant Equipment, Technology, and Processes

A partner’s capabilities are defined by their tools and technology. Look for modern equipment, such as 5-axis CNC machines, which are essential for producing complex geometries with high precision. Ask about their investment in automation and data-driven processes. A partner who invests in technology is a partner who is investing in your future success.

5. Experienced Project Management

The most advanced machines are ineffective without skilled people to run the projects, which requires a clearly defined complex project process to ensure success.

As Jabil’s Business Development Director, Bob Barnhart, notes, “The Project Managers are the conductors of this orchestra and must be empowered.” You need a partner with a strong project management team and a transparent workflow to ensure your project stays on track and communication flows smoothly.

6. Transparent and Rapid Communication

Poor communication is a significant red flag. In today’s fast-paced environment, you need a partner who responds quickly, provides proactive updates, and is transparent when issues arise. A 48-hour email response time is unacceptable when your production schedule is on the line.

7. Scalability and Production Flexibility

Your needs will change over time. A great partner can support you through every stage, from initial prototypes (1-100 units) to full-scale production (10,000-100,000 units). Inquire about their experience with projects that have scaled and their flexibility in handling both low-volume and high-volume runs.

8. Robust Supply Chain and Material Traceability

Your partner’s supply chain is an extension of your own. They must have a robust system for qualifying their raw material suppliers and be able to provide full material traceability. This is non-negotiable for industries like aerospace and medical devices, where material integrity is critical.

9. Proven On-Time Delivery (OTD) Record

Late parts can cause cascading delays and significant costs. Don’t just take their word for it; ask for their On-Time In-Full (OTIF) delivery metrics and inquire about their systematic process for guaranteeing on-time delivery.

A reliable partner will track this data and should be willing to share it. An OTIF rate below 95% warrants further investigation.

10. A Proactive Partnership Mindset

Finally, assess their mindset. Are they simply trying to win a bid, or are they genuinely interested in your product and long-term success? A true partner asks insightful questions, offers creative solutions, and invests in building a collaborative relationship. This cultural fit is often the secret ingredient to a successful, long-term partnership.

Making Your Final Decision with Confidence

This checklist provides a technical framework, but the right choice often comes down to experience and a holistic view of the partnership. It requires moving beyond the quote and assessing the total value a partner brings to your business.

We have seen clients select a new supplier based on a 20% lower price, only to face significant hidden costs from production delays, poor communication, and quality rework. The most successful decisions look beyond the unit price and consider the Total Value of Ownership (TVO), factoring in the costs of risk and the value of reliability.

Similarly, a partner who passively accepts your complex designs without offering any proactive DfM feedback isn’t demonstrating expertise; they are demonstrating a lack of engagement. The most valuable partners are those who challenge you collaboratively, using their manufacturing experience to help you create a more robust and cost-effective product before production begins.

Ultimately, selecting the right high-precision manufacturing partner is about mitigating risk and building a foundation for future growth. By using this manufacturing partner checklist to conduct a thorough, data-driven evaluation, you can move forward with a partner who will not only make your parts right but will also contribute to your long-term success.