Stop getting inaccurate quotes and wasting time on back-and-forth emails. This guide provides a proven, step-by-step process for creating an RFQ that gets you fast, accurate pricing for your high-precision CNC machining needs. You’ll learn exactly what information to include to protect your project and budget.

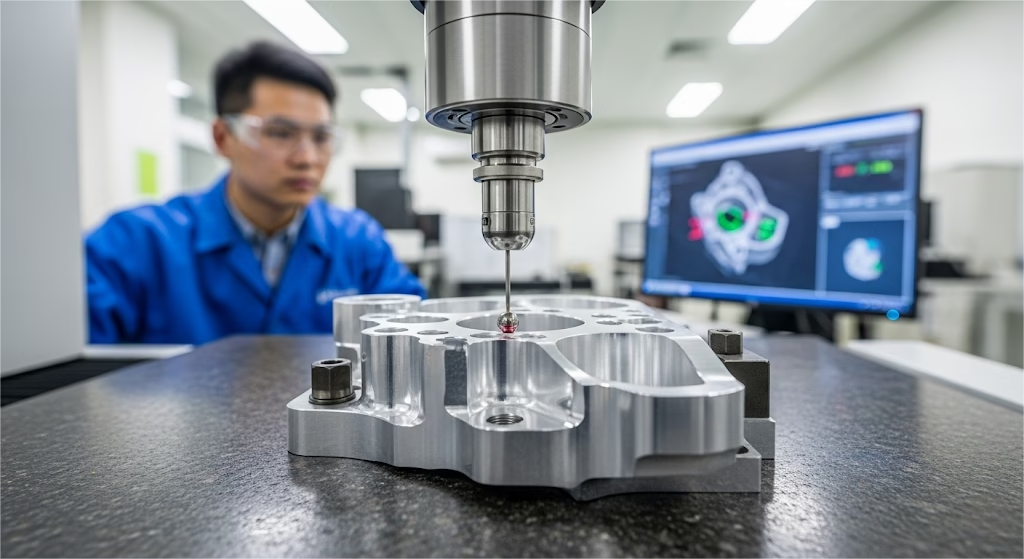

An effective RFQ for high-precision CNC machining services requires a complete technical package. This must include a 3D CAD model (as a .STEP file) for geometry, a 2D technical drawing (.PDF) defining all tolerances, GD&T, surface finish, and material specifications, and a table listing required quantities.

Now that you have the basic formula, read on to discover the advanced techniques that separate amateur RFQs from professional ones, including how to avoid common mistakes that silently inflate your costs.

Why Your RFQ Dictates 80% of Project Success

From Price Inquiry to Project Blueprint

Let’s reframe how you think about the RFQ. It’s not just a form you fill out to get a price. An effective RFQ for high-precision CNC machining services is the foundational document for your project’s success.

It’s where you and your future manufacturing partner agree on the definition of “done right.” A complete RFQ ensures that your design intent is perfectly understood, leaving no room for interpretation or costly assumptions.

The Hidden Costs of an Incomplete RFQ

A vague RFQ does more than cause frustration; it has tangible, negative impacts on your budget and timeline. Consider these figures:

- The “Risk Premium”: When a machine shop receives an incomplete RFQ, they can’t accurately assess the complexity. To protect themselves from unforeseen challenges, they often add a “risk premium” of 15% to 25% to the quote. Your lack of detail is directly costing you money.

- Wasted Engineering Time: Industry studies show that engineers can spend up to 30% of their time in back-and-forth clarifications with suppliers. Imagine what you could accomplish with that time back—more innovation, more design, less administrative churn.

- The Exponential Cost of Tolerances: Tighter tolerances are expensive, but how expensive? The relationship isn’t linear. A common rule of thumb is that for every time you halve a tolerance, the machining cost can double or even quadruple. A poorly defined RFQ that doesn’t specify which tolerances are critical forces the supplier to price for the tightest possible interpretation, dramatically inflating the cost.

Build Authority with a Professional RFQ

A professional RFQ does more than just communicate technical details; it builds your authority within your own organization.

When procurement questions why you’ve chosen a supplier that isn’t the absolute cheapest, your detailed RFQ is your evidence. It demonstrates that your decision is based on a supplier’s ability to meet critical, well-documented technical requirements.

As Randy Altschuler, CEO and Co-founder of Xometry, puts it, “An accurate, information-rich 3D CAD model is the single most important element in getting a fast, accurate quote and a high-quality part. It is the source of truth.”

When your RFQ is the undisputed source of truth, your technical recommendations carry undeniable weight. It allows you to lead the conversation, ensuring that critical engineering decisions aren’t undermined by a purely cost-driven approach.

A Checklist from “Essential” to “Exceptional”

Now, let’s get into the tactical details. Building the perfect RFQ package is about layering information correctly.

We’ll start with the non-negotiable basics and then add the professional touches that set you apart.

Achieving a 90+ “RFQ Integrity Score”

Think of your RFQ’s quality in terms of a score. A package scoring above 90 is one that a supplier can quote quickly and accurately, without needing to ask a single question. Here’s what that looks like:

- The 3D Model (.STEP): Your Single Source of Truth. The 3D CAD model is the undisputed foundation. It contains all the geometric data the CNC machine will follow. Providing a universal format like .STEP ensures any supplier can use it. This file dictates the part’s shape and size.

- The 2D Engineering Drawing (.PDF): The Voice of Your Intent. The 2D Engineering Drawing (.PDF): The Voice of Your Intent. The 2D drawing is where you communicate everything the 3D model can’t. This is where you add all the critical drawing information.

- Tolerances & GD&T: Specify all required tolerances, especially for critical features.

- Surface Finish: Define the required surface roughness (Ra) for specific surfaces.

- Technical Notes: This is the home for vital details like deburring requirements, material specifications, and post-processing instructions.

- The RFQ Information Table: The Commercial Details. This is a simple but crucial list that includes:

- Material: Be precise. “Aluminum 6061-T6,” not just “Aluminum.”

- Quantities: Provide quantity breaks (e.g., 10, 50, 100 pieces) to get the best possible pricing structure.

- Finishing: Clearly state any required post-processing like anodizing, heat treatment, or powder coating.

As Greg Paulsen, Director of Application Engineering at Fictiv, notes, “We often see a disconnect between the 3D model and the 2D drawing…A successful RFQ package is one where the 2D drawing serves to clarify and add critical information…that complements the 3D model, rather than contradicting it.”

Get Your Design Right Before Manufacturing

A clear RFQ is the first step. Our Design for Manufacturability (DfM) experts can help you optimize your parts for cost and efficiency. Let’s ensure your project is a success from the start.

Clearly Communicate Your “Design Intent”

An exceptional RFQ goes beyond dimensions; it explains why certain features are critical.

This helps the machinist make intelligent decisions that protect your part’s function.

- Mark “Critical-to-Function” (CTF) Features: On your 2D drawing, highlight the 3-5 features that are absolutely essential for your part to work. Is it the diameter of a hole for a press-fit bearing? The flatness of a sealing surface? Mark them clearly.

- Add Functional Notes: A simple note like, “This surface mates with Part B; flatness is critical for sealing,” provides invaluable context. It transforms the machinist from a machine operator into an informed partner in your success.

Three Mistakes That Can Derail Your Project

These aren’t hypotheticals; they are real, costly mistakes I’ve seen happen.

- The Case of the “Assumed” Deburring: An engineer designed a complex manifold with internal cross-drilled holes. They assumed the shop would naturally deburr these sharp internal edges. They didn’t. The first batch of parts had burrs that damaged O-rings, rendering them useless and causing a three-week delay. The takeaway: Never assume. If you need a part to be free of burrs, write it down as a technical note.

- The Catastrophe of the Missing “-T6”: A critical aerospace part was specified as “Aluminum 7075.” The engineer forgot to add the “-T6” temper designation. The shop used the readily available, untreated material. The parts were dimensionally perfect but lacked the required strength and failed during testing, scrapping the entire run. The takeaway: Material specifications must be complete and precise, including temper and any applicable standards.

- The Inflated Cost of the Copied Title Block: To save time, an engineer copied the title block from a high-precision project for a simple bracket. They forgot it contained a default tolerance block specifying an unusually tight ±0.05mm for all unspecified dimensions. The quotes came back three times higher than expected because every shop priced in the unnecessary precision. The takeaway: Always check your general tolerances. They are a silent driver of cost.

| Mistake | Impact | Solution |

|---|---|---|

| Vague Material Specs | Wrong material, part failure | Specify full designation (e.g., 6061-T6) |

| “Assumed” Requirements | Rework, delays, added cost | Note all needs (deburring, cleaning) |

| Incorrect General Tolerances | Inflated quotes, unnecessary precision | Use standard tolerances (ISO 2768-m) |

Using Your RFQ to Screen, Manage, and Optimize Suppliers

An RFQ does more than get you a price; it’s a powerful diagnostic tool.

The way a supplier responds to your meticulously prepared RFQ for high-precision CNC machining services tells you everything you need to know about their capabilities, processes, and even their business model.

Your RFQ as a “Supplier Capability Test”

Stop sending your RFQ out to dozens of random shops. Instead, think of it as a test. Send your perfected RFQ to three distinct types of suppliers and watch what happens:

- The Digital Platform (e.g., Xometry, Protolabs): You’ll likely receive an automated quote within minutes or hours. This tells you they are fast, data-driven, and excellent for prototypes and standard parts where speed is the priority.

- The Tech-Oriented Machine Shop: You’ll get a detailed quote back in 24-48 hours, often from an engineer, sometimes with a few suggestions for Design for Manufacturability (DFM). This is your ideal partner for complex parts and long-term, high-value relationships. They read your design intent.

- The Traditional Job Shop: The response might take several days and be a simple email with a single price. While they may offer competitive pricing on simpler parts, the lack of a detailed breakdown could be a red flag for high-precision work that requires rigorous process control.

By analyzing not just the price, but the response itself, you perform an effective, low-cost supplier qualification before you’ve even spoken to anyone.

Proactively Define Quality with a Key Dimension Inspection Plan

Engineers specify tolerances, but most don’t consider how those tolerances will be verified. This ambiguity leads to higher costs, as the supplier must price in the assumption of 100% inspection for every dimension.

Take control of this process. Alongside your 2D drawing, include a simple “Key Dimension Inspection Plan.”

This is a small table listing your 3-5 CTF dimensions and defining the inspection requirements for each (e.g., “100% CMM check for first article, 10% sampling for production run”). This simple document does two things:

- It demonstrates your manufacturing knowledge, earning you immediate respect.

- It allows the supplier to quote based on a defined, limited inspection scope, which can significantly lower your cost.

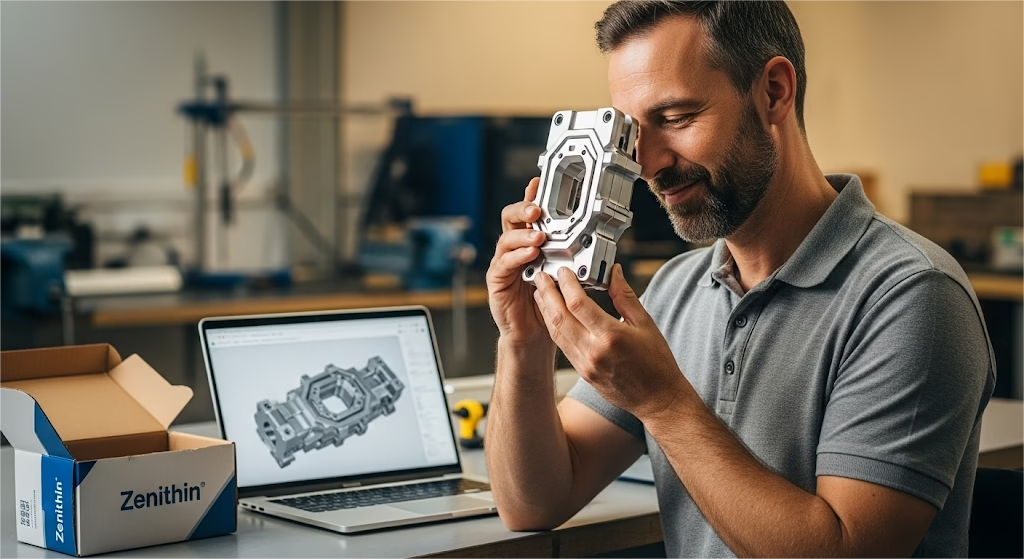

Separate Your “Prototype RFQ” from Your “Production RFQ”

Using the same RFQ for both prototyping and mass production is a common but critical mistake. The supplier who can make five parts for you quickly is rarely the right partner to make 5,000 parts consistently and cost-effectively.

You need two distinct RFQ templates:

- Prototype RFQ: The goal here is speed and feedback. Your RFQ should explicitly state “Prototype Stage – DFM feedback is highly encouraged.” Cost is secondary to learning and validating your design.

- Production RFQ: The goal is cost, consistency, and quality control. Your design is locked. This RFQ package should be more robust, including requests for quality certifications (like ISO 9001) and process control documentation.

Use the prototyping phase not just to test your design, but to refine your RFQ documents. Once your design and your documentation are battle-tested, you can confidently source a production partner.

Conclusion: Become the Engineer Who Defines the Rules of the Game

An RFQ is far more than a request; it’s a reflection of your own engineering rigor. By implementing the strategies we’ve discussed, you’re doing more than just improving a document. You are taking proactive control over project outcomes.

A truly exceptional RFQ brings you more than an accurate quote. It saves you invaluable time, preemptively eliminates risks, controls costs, and most importantly, solidifies your position as a credible, authoritative engineering professional.

You will no longer be reacting to manufacturing problems; you will be preventing them before they ever happen. This is how you move from being a participant in the manufacturing process to being the one who defines its success.

The next time you prepare an RFQ for high-precision CNC machining services, you won’t just be asking for a price—you’ll be setting the stage for a successful project.

Ready to Partner with a DfM Expert?

You’ve learned how to create the perfect RFQ. Now, partner with a team that speaks your language and can elevate your design for optimal manufacturing.

References & Notes

[1] Xometry: The quote from CEO Randy Altschuler highlights the critical role of a complete 3D CAD model as the “source of truth” for automated quoting and manufacturing, a core principle of digital manufacturing platforms.

[2] Fictiv: The insight from Director of Application Engineering Greg Paulsen emphasizes the common conflict between 2D drawings and 3D models. His view underscores the need for documentation to be complementary, not contradictory, to avoid process delays.