Choosing the wrong CNC machine shop can stall your project, even if the prototype looks perfect. This guide gives you a proven framework to find a true manufacturing partner. We’ll show you how to vet suppliers and scale from 1 to 10,000+ parts without risk.

Selecting the right CNC manufacturing partner involves vetting them beyond the price quote. Prioritize partners who provide expert Design for Manufacturability (DfM) feedback avant prototyping. Verify they have a unified Quality Management System (QMS) and the technical capability to scale from prototype to low-volume and full production.

In the rest of this post, I’ll reveal the 4 critical questions you doit ask any potential supplier. You’ll also learn the “Total Cost Fallacy” that traps most engineers into choosing the wrong partner.

The Total Cost Fallacy: Why Your Time Is the Most Expensive Part

As an engineer, your day shouldn’t be spent in “RFQ Hell”—blasting drawings to 10 different suppliers and then trying to decipher a pile of garbage quotes. Your time is for engineering, not for managing bad suppliers.

Procurement teams often focus on the unit price. They’ll show you a spreadsheet where Supplier A is $5.00/part and Supplier B is $5.50/part, demanding you justify the 10% difference. This is the “Total Cost Fallacy.” It ignores the most expensive variable: your time.

Let’s use a simple formula:

True Total Cost = Quoted Price + (Your Engineering Management Cost)

Let’s say your time is valued at $100/hour.

- You choose the “cheap” Supplier A ($5.00/part). You then spend 15 hours in back-and-forth emails arguing about tolerances, holding video calls to explain the assembly, and personally inspecting the faulty parts they delivered.

- Your Hidden Cost: 15 hours x $100/hour = $1,500.

- For a 100-piece run, that’s an extra $15 par pièce. Your “cheap” part actually costs $20.00.

- Now look at the Partner ($5.50/part). They deliver correct parts the first time.

- Your Hidden Cost: 0 hours.

- Your True Cost: $5.50.

We see this every day. We often receive drawings for parts, like an external housing, with an unnecessarily tight tolerance of ±0.005mm. A “Shop” will just quote it high or, worse, try and fail.

Our process is to call you and ask, “We see this tolerance and can absolutely hit it, but it will add 40% to the cost. Is this surface a functional fit, or can we relax it to ±0.05mm?”

Nine times out of ten, the answer is, “Oh, thank goodness you called. That was just our title block default.”

A partner’s job is to save you that 40%. Your goal isn’t to find the lowest quote; it’s to find the partner with zero management cost.

Part 2: What “Stage” Is Your Project Really In?

A huge part of finding the right partner is first understanding what you’re asking for. The needs—and the risks—of a 1-piece run are completely different from a 10,000-piece run. Let’s quantify this gulf. Most projects fall into one of three distinct stages, each with its own goal and its own critical risk.

| Stage | Typical Quantity | Objectif principal | Critical Hidden Risk |

|---|---|---|---|

| Prototype Stage | 1 – 10 pieces | Speed & Design Validation | Using non-scalable “craft” methods. |

| Low-Volume | 50 – 5,000 pieces | Process Validation & Market Test | Batch-to-batch inconsistency. |

| Production de masse | 10,000+ pieces | Cost Efficiency & Stability | Supplier process breaks at scale. |

- Prototype Stage (1 – 10 pieces)

- Goal: Pure speed and design validation. You need parts on your desk in 1-5 days.

- Typical Cost: High, often $50 – $500+ per part, as all setup costs are absorbed by a few pieces.

- The Hidden Risk: Your supplier uses non-repeatable “craft.” They might use manual polishing, temporary fixtures, or complex setups to create a “perfect” part. The process isn’t documented or scalable, and you’ve just approved a design that is a manufacturing dead end.

- Low-Volume / Bridge Production (50 – 5,000 pieces)

- Goal: Process validation, market testing, and bridging the gap before high-volume tooling is ready. This is a serious, independent $9.2 billion global market—not just “more prototypes.”

- The Hidden Risk: Batch-to-batch inconsistency. This is especially true with automated platforms that may farm your 500-piece order out to three different shops to meet capacity. You get three slightly different versions of your part and have no single source of quality control.

- Mass Production (10,000+ pieces)

- Goal: Cost-per-part efficiency and supply chain stability, achieved through automation and dedicated tooling.

- Typical Lead Time: 4-12 weeks, because this now includes creating robust, custom fixtures and full process validation.

- The Hidden Risk: The supplier who was a hero on your 500-piece run simply doesn’t have the automation, quality management system (QMS), or capacity for 10,000 pieces. Their process breaks under the strain.

Look at that list again. The most dangerous transition, where most engineering projects fail, is that jump from Prototype to Low-Volume.

This is why you must vet for production capability, even when you are only ordering your first prototype. You need a partner who uses the prototype stage to validate the processus de production, not just the part.

Part 3: The Engineer’s “Partner” Vetting Checklist

You’re busy. You don’t have time to guess. When you’re vetting a new CNC supplier, you need to quickly separate the “Yes-Men” from the true engineering partners.

Here is a 4-point checklist. These are the “touchstone” questions that reveal the truth about a supplier’s capability and mindset.

Vetting Point 1: The DfM Feedback

This is the most important test. Send your part drawing and observe how they respond.

- 🚩 Red Flag (The “Shop”): They send back a quote within two hours, no questions asked. They are a “Yes-Man” just trying to win the order.

- ✅ Green Flag (The “Partner”): They send back an email avant the quote, saying: “Our engineers are reviewing your print and would like to confirm a few things. We see the ±0.01mm tolérance on surface B. Is this a critical fit? If we can open it to ±0.03mm, we can avoid a secondary grinding operation and save you 20% on the part. Please advise.”

This is not an annoyance; this is the most valuable service you can receive. As Dr. David M. Anderson, author of ‘Design for Manufacturability‘, notes, as much as 80% of a product’s cost is locked in during the design phase.

A partner who gives you DfM feedback avant production is actively saving you money and preventing future failures.

Vetting Point 2: Process Consistency

You must find out if your supplier is a unified manufacturer or just a middleman (like many automated platforms).

- Your Question: “Will my prototypes and my low-volume production order be manufactured under the même Quality Management System (QMS) and in the même facility?”

- 🚩 Red Flag: “We have a partner network…” or “We use a different supplier for prototypes to make them faster.”

- ✅ Green Flag: “Yes. We use the prototype run to validate the exact process and fixtures that will be used for your First Article Inspection (FAI) and your production run. The process is identical.”

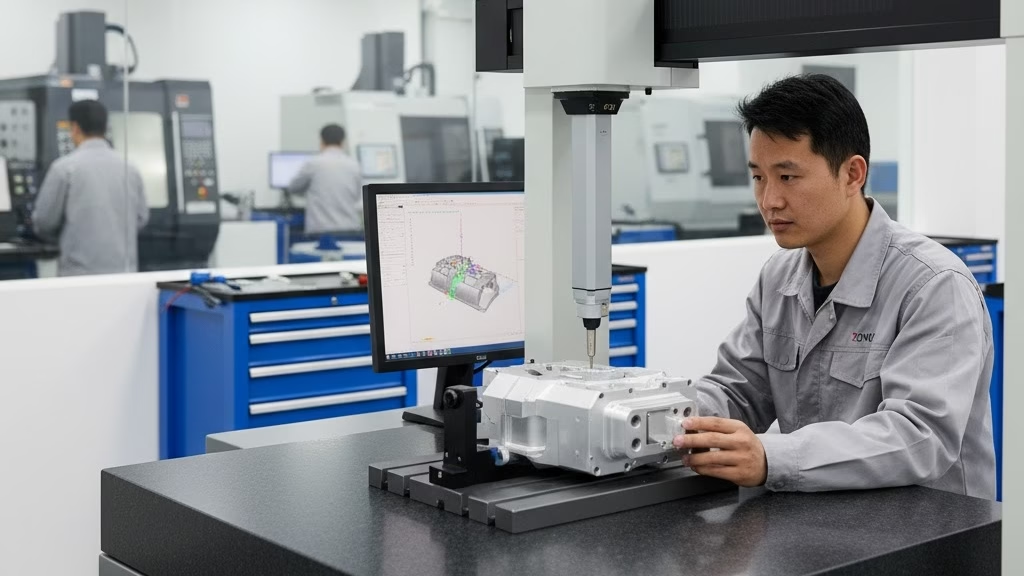

Vetting Point 3: Quality Assurance

Don’t accept vague promises. Ask for the deliverables.

- Your Question: “What specific quality reports can you provide with my parts? Can I get a full CMM inspection report for 100% of the parts, or just an FAI?”

- 🚩 Red Flag: “Don’t worry, our QC department checks everything before it ships.”

- ✅ Green Flag: “We can provide whatever you need. Our standard is an FAI report, but we can happily provide full CMM reports for every part, material certifications, and certs for all outside processes like anodizing.”

Vetting Point 4: Engineering Communication

When (not if) a technical issue arises, you need to know who you will be talking to.

- Your Question: “If I have a technical question or need to make a design change mid-run, who is my direct point of contact? Is it a salesperson or an engineer?”

- 🚩 Red Flag: “You can just email our sales team, and they will pass the message along.”

- ✅ Green Flag: “You will be assigned a dedicated project engineer. You will have their direct email and phone number, and they work directly with our CAM programmers to resolve any issues.”

Part 4: Our Solution: The Scalable “Prototype to Production” Workflow

So, what does this “partner” process actually look like in practice? It’s not a black box. It’s a transparent, scalable roadmap designed to move your part from idea to inventory with zero hand-offs and zero surprises.

The entire process is designed to avoid what Karl T. Ulrich, Vice Dean of Entrepreneurship & Innovation at the Wharton School, calls the “prototyping trap.” He states, “A common failure mode is using a prototyping method… that is not representative of your actual production process.”

Our workflow is the antidote to that trap. Here’s how it works.

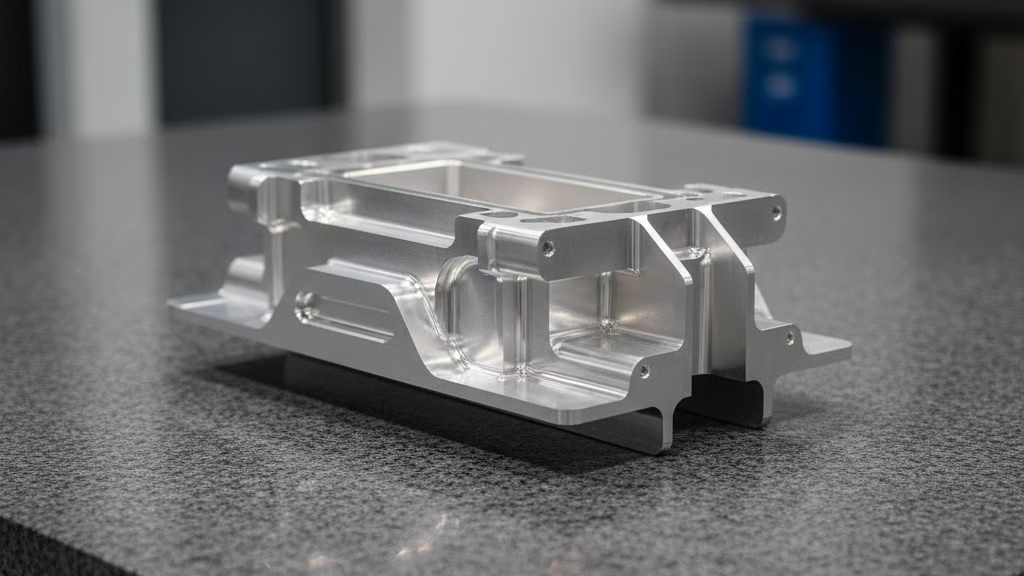

Stage 1: The Production-Intent Prototype (1-10 pieces)

This stage is all about speed et foresight.

- Votre action : You submit your design and project requirements.

- Our Action: We don’t just “hit print.” Our engineers immediately review your design through the lens of mass production.

- Your Deliverable: You receive two things:

- Your fast-turnaround prototype part.

- A professional DfM (Design for Manufacturability) report. This report might say, “We made this part as-drawn, but if you plan to scale, we recommend changing this internal radius from R0.1mm to R0.5mm. This will not affect your design’s fit, but it will allow us to use a standard tool in production, cutting your unit cost by 30%.”

Stage 2: The Process Validation Run (50-1,000 pieces)

This is where we industrialize the process. We are no longer just making a part; we are perfecting the recipe to make it 10,000 times.

- Votre action : You approve the DfM changes and place your first low-volume order.

- Our Action: We now build the infrastructure for scale. This includes creating custom fixtures to guarantee repeatability, locking in the CAM toolpaths, and establishing all the in-process quality control stations.

- Your Deliverable: A batch of highly consistent parts and a formal Rapport d'inspection du premier article (FAI) that validates every dimension and feature. You now have a proven, documented, and repeatable manufacturing process.

Stage 3: Efficient, Scalable Production (10,000+ pieces)

This is the “easy” part because all the hard engineering work is done. This stage is about pure execution.

- Votre action : You send a PO for a production run.

- Our Action: We activate the proven workflow, fixtures, and QMS defined in Stage 2. This is often where automation, like robotic part-tending or dedicated CMM programs, comes in to drive down costs.

- Your Deliverable: Predictable, on-time, and on-budget delivery of your high-quality parts, batch after batch, with no deviation from the FAI you already approved.

Conclusion: Don’t Just Buy a Part—Invest in Peace of Mind

As an engineer, your primary role is innovation and design, not managing supplier relationships. Your energy shouldn’t be drained by chasing down deliveries, arguing about tolerances, or re-inspecting bad parts.

Choosing the wrong “Shop” will exhaust your most valuable resource: your time. Choosing the right “Partner” will amplify your capability, making you more effective and successful.

It’s time to stop the “RFQ Hell” and find a partner who speaks your language.

Take the first step. Send us your most complex drawing today.

We make you this promise: the first thing you get back from us won’t be a quote. It will be a professional DfM analysis from our engineering team.

Let’s build your prototype with a production mindset, right from day one. Let’s build your part, and let’s build a partnership.

Ready to Partner With an Engineering-First Supplier?

You’ve done the design work. Now let our engineers review your files and provide the DfM feedback needed to make your project a scalable success.

Références et notes

[1] On DfM & Cost: The oft-cited statistic that 70-80% of a product’s life-cycle cost is locked in during the design phase is a foundational concept in manufacturing, notably articulated by experts like Dr. David M. Anderson in his work on Design for Manufacturability.

[2] On Partnership: The quote regarding Toyota’s supplier relationships is adapted from the core principles described by Dr. Jeffrey K. Liker in “The Toyota Way,” which emphasizes long-term partnerships and mutual improvement over simple cost-down negotiations.

[3] The Prototyping Trap: This concept, as referenced by Karl T. Ulrich, highlights a common failure mode where prototypes are built using methods (e.g., 3D printing, manual finishing) that are not representative of the final production process, leading to costly redesigns and delays.