Stop guessing on your CNC sourcing strategy. This data-driven guide provides a definitive framework for comparing Local vs. Overseas (China) CNC Machining. We help you analyze the réel factors—Total Cost of Ownership (TCO), lead times, quality control, and IP risk—so you can make a decision with confidence.

The decision between local (US) and overseas (China) CNC machining hinges on a framework of four key factors: Total Cost of Ownership (TCO), lead time, quality consistency, and IP risk. Local sourcing offers speed, lower risk, and IP security, making it ideal for prototypes. Overseas sourcing provides lower unit costs at scale but includes tariffs, shipping delays, and higher management overhead.

Now that you understand the core tradeoff, dive deep. We provide real-world “pitfall” examples and a 4-step decision tree to help you choose the right supplier for your exactes project.

Why “Total Cost of Ownership (TCO)” is the Only Metric You Should Care About

The Iceberg: Landed Cost vs. Hidden Costs

That $60 unit price from China is just the tip of the iceberg. What you don’t see are the substantial costs lurking below the surface.

A savvy purchasing manager knows the difference between a simple Landed Cost and the comprehensive Coût total de possession (TCO).

First, let’s look at the basic calculation, the Landed Cost. This is the most straightforward cost to calculate:

-

Landed Cost = Unit Price + Freight (Ocean/Air) + Tariffs (like the 25% Section 301 tariff) + Customs Fees + Insurance

This formula gets the part to your warehouse door. But it stops there. It completely ignores the réel costs of managing an overseas supplier.

The metric that finance directors and successful procurement teams use is the Coût total de possession (TCO):

-

TCO = Landed Cost + Hidden Costs + Risk Costs

What are “Hidden Costs”?

This is the “management friction” that drains your team’s time and energy. How many hours will your engineers spend in late-night video calls? How many back-and-forth emails will it take to clarify a 0.05mm tolerance, potentially losing meaning in translation? This internal staff time is a real, measurable cost.

What are “Risk Costs”?

This is the financial impact of what could go wrong. It’s the cost of:

-

Shutting down a production line because your container is stuck in customs.

-

Paying for emergency air freight to fix a quality issue.

-

A competitor stealing your IP.

-

Scrapping an entire batch that fails inspection.

En tant que Rosemary Coates, Executive Director of the Reshoring Institute, puts it, “The procurement process has historically been based on piece price, but that’s a fatal flaw. When you factor in the 25% tariffs, rising transportation costs, [and] risks… the ‘low piece price’ from China often results in a higher Total Cost of Ownership.”

The Four Pillars of Your Sourcing Decision: A Comparative Analysis

Pillar 1: Cost

China’s Ecosystem vs. Local’s Predictability

At first glance, the cost comparison seems simple. The average CNC machining shop rate in the US can range from $50 to $100 per hour, while a Chinese supplier might quote $8 to $30 per hour.

However, this hourly rate is deceptive.

First, the 25% Section 301 tariff on many Chinese goods immediately closes this gap. But the real story is more complex. China’s true cost advantage often isn’t the hourly rate; it’s the manufacturing ecosystem.

Does your part also need to be anodisé, powder-coated, silk-screened, and assembled?

-

In China: A single, qualified CNC shop will often manage all these post-processing steps under one roof, or within a 5-kilometer radius. This “one-stop” integration dramatically lowers your total project cost and simplifies your vendor management.

-

In the US: You might have to coordinate with 3 or 4 different vendors (the machine shop, the anodizer, the painter), adding management overhead and cost at every step.

On the other hand, a local supplier offers a massive advantage in TCO predictability. The price you’re quoted is the price you pay.

There are no surprise tariffs, no international freight volatility, and, most importantly, the “hidden management costs” are minimal. A 10-minute phone call to resolve a complex issue is always cheaper than a 3-day email chain across 12 time zones.

Pillar 2: Lead Time

Local Speed vs. China’s “Speed at Scale”

When your project is on a tight deadline, lead time can become the single most important variable. This is where the local vs. overseas decision requires careful thought.

For pure, raw speed on small quantities, local US suppliers are the undisputed champions.

-

A local machine shop can often take your design from a CAD file to a physical part in your hands in 1 to 3 weeks.

-

For urgent prototypes, many can expedite the process down to just 3 to 5 days.

-

The reason is simple: There is no ocean freight, no customs clearance, and no risk of port congestion.

However, many purchasing managers make a critical miscalculation here. They assume “China is always slow.” The truth is, China offers a completely different kind of speed: Speed at Scale.

A local US shop is fantastic for 10 prototypes. But what happens when you validate that design and need 5,000 units of that part delivered in the next four weeks? Most local shops simply do not have the capacity, the immediate raw material stock, or the 24/7 labor model to manage that kind of rapid ramp-up.

This is China’s unique, and often misunderstood, advantage. The manufacturing ecosystems are built for massive, rapid scaling. They can move from prototype to high-volume production with a velocity that is often unmatched.

Real-World Pitfall: The “Urgent Air Freight” Trap

Here’s a story we’ve seen play out more than once: A company, desperate to get parts for a critical trade show, pays a fortune for “5-day urgent air freight” from China. The factory produces the parts in 3 days. But the package gets stuck at the airport for four days.

Why? The supplier failed to provide the correct MSDS paperwork for a small battery in the sub-assembly, or a part with a magnet failed the required inspection. The shipment misses the trade show.

The lesson is critical: Overseas lead time is not just about production time; it’s about logistics and compliance expertise. A supplier with a weak logistics team can nullify all their manufacturing advantages.

Pillar 3: Quality

Consistency vs. The High-Stakes Sourcing Game

When it comes to quality, the decision framework isn’t about “US quality” versus “Chinese quality.” Top-tier Chinese suppliers can achieve tolerances (e.g., ±0.005mm) and certifications (like ISO 9001) that are identical to their US counterparts.

The real difference is consistency.

Sourcing from a local US supplier offers high predictability. Quality is stable from the first part to the last. If an issue arises during production (in-process QC), you can pick up the phone, speak the same language, and resolve it in hours. You can even visit the shop floor.

Sourcing from China is a high-stakes game because the market is deeply polarized.

-

You have “Elite Suppliers” who manufacture for global brands. Their le contrôle de la qualité, machinery, and documentation are world-class.

-

You have “Workshop Suppliers” who compete aggressively on price. They are the primary source of quality failures, IP risks, and “bait-and-switch” tactics.

Your entire job as a procurement manager is to tell the difference.

Real-World Experience: The “Perfect Sample” Trap

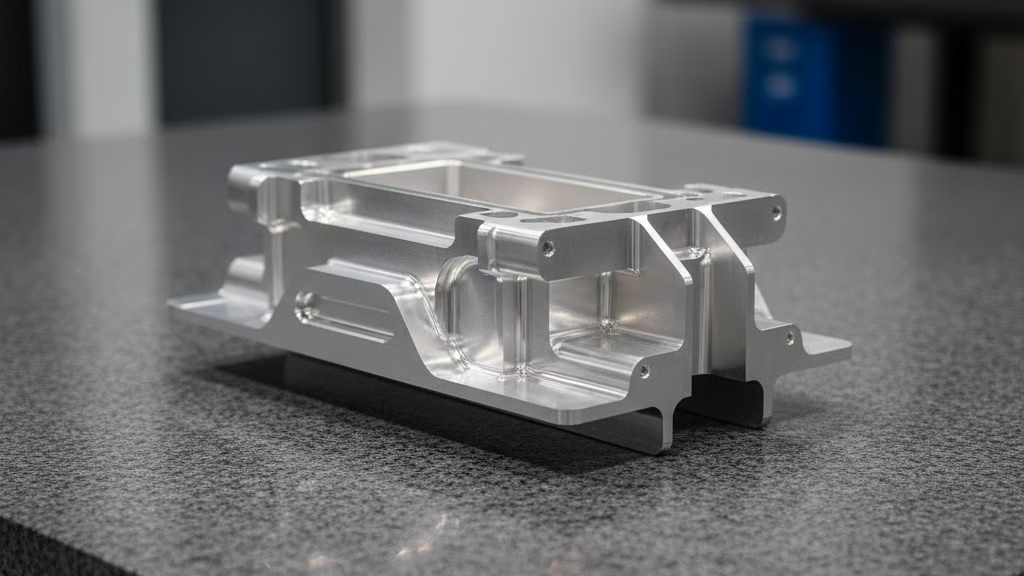

A classic pitfall we’ve seen clients experience is the “perfect sample.” A US startup, developing a new electronic enclosure, received 5 sample units from a low-cost Chinese supplier. The quality was flawless—perfect anodizing, exact tolerances.

Based on this, they confidently placed a 5,000-piece production order.

-

Batch 1 (1,000 pcs): Arrived with severe color variation in the anodizing.

-

Batch 2 (2,000 pcs): Critical snap-fit features were out of tolerance, making assembly impossible.

The supplier had used their best machines and most skilled technicians for the samples. For the mass-production run, they outsourced it to a cheaper, smaller workshop to protect their profit margin.

How to Guarantee Overseas Quality:

You cannot be passive. You must proactively manage quality.

-

Demand a Pilot Run: Never move directly from sample to mass production. Insist on a small pilot run (e.g., 100-200 pieces) using the réel production line and process. This is the only way to verify consistency.

-

Define Your AQL: Don’t just send a drawing. Provide a clear AQL (Acceptable Quality Limit) standard and “limit samples” (the worst-case part you would still accept) for cosmetic finishes.

-

Require Full Documentation: Mandate fully traceable, English-language Material Test Reports (MTRs) and a full dimensional inspection report for every shipment.

Pillar 4: Risk

Local Security vs. The High-Risk, High-Reward Overseas Game

For a CTO or a procurement manager at a technology-driven company, this is often the pillar that matters most.

Sourcing locally in the US is, by default, the low-risk option.

-

IP Security: Your intellectual property is protected by US law, and legal recourse is straightforward.

-

Supply Chain Visibility: You can visit your supplier’s factory. You can see your parts being made. This transparency is invaluable.

Sourcing from China fundamentally involves a higher-risk, higher-reward calculation. The risks are not just financial; they are strategic.

-

IP Protection: This is the number one concern for innovative companies.

-

Geopolitical Factors: Supply chains can be disrupted by tariffs, trade disputes, or shipping crises.

-

Contract Enforcement: If a dispute arises, enforcing a contract overseas is significantly more complex and expensive than doing so locally.

Many companies make a fatal mistake regarding IP.

En tant que Dan Harris, founder of the China Law Blog, states, “Assuming your US patent or a US-style NDA will protect you in China is a fatal and expensive mistake. Your US NDA is worthless in China.”

This risk doesn’t mean you can’t source from China; it means you must do so with a clear-eyed strategy.

How-to Guide: An IP Protection Action Plan for China

If you choose to work with an overseas supplier, do not send a single drawing until you have a basic defense in place.

-

Sign an NNN Agreement: Before any RFQ, have your potential supplier sign a China-specific NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreement. It must be bilingual (Chinese-English) and enforceable under Chinese law.

-

Separate Your Manufacturing: If possible, “black box” your design. Have the core, proprietary component manufactured locally in the US, and outsource the non-critical components (like the housing or brackets) to China.

-

File Defensive Registrations: Register your trademarks and any relevant design patents in China immediately. This is a low-cost “defensive” move that prevents bad-faith actors from registering votre brand before you do.

Need to Validate a Supplier’s Quality & Risk Profile?

This framework is the first step. The next is vetting. Talk to our experts about how to audit a potential supplier’s quality systems, IP protections, and TCO model before you commit.

Part Four: Practical Application

So, Who Should I Choose? Use This Decision Tree to Find the Answer

You’ve analyzed the four pillars. Now, let’s put this framework into practice. The “right” supplier isn’t a simple “US vs. China” choice; it’s a strategic decision that changes with every project.

Find your project type below to see a clear recommendation.

| Project Scenario | Caractéristiques principales | Primary Driver | Recommended Decision |

|---|---|---|---|

| 1. Rapid Prototyping | 1-50 pieces; High IP sensitivity; Design in flux. | Speed & IP Security | Local Manufacturing |

| 2. Low-to-Mid Volume | 100-5,000 pieces; Design frozen; Needs multiple processes (e.g., anodizing). | TCO & “One-Stop” Ecosystem | Evaluate “Elite” Overseas |

| 3. High-Volume / Mature | 50,000+ pieces; Mature product; Predictable 6-8 week lead time. | Cost at Scale | Overseas Manufacturing |

| 4. Strategic / Regulated | Aerospace, Defense (ITAR), or critical medical device. | Risk & Compliance | Must Use Local |

-

Characteristics: You need 1 to 50 pieces. The design is still being iterated. Time-to-market is the most critical factor, and the design is a core part of your company’s intellectual property.

-

Decision: Local Manufacturing.

-

Reasoning: This isn’t a cost decision; it’s a speed and security decision. Local suppliers provide the turn-around speed (1-5 days) necessary for rapid iteration. More importantly, your IP is secure under US law, and you can have high-bandwidth conversations with the engineers to quickly resolve design changes.

-

Characteristics: You need 100 to 5,000 pieces. The design is finalized. The part requires multiple post-processing steps (e.g., Usinage CNC + anodizing + silk-screening).

-

Decision: Evaluate “Elite” Overseas Suppliers.

-

Reasoning: At this volume, TCO becomes a major factor. The “one-stop ecosystem” advantage of a top-tier Chinese supplier (as discussed in Pillar 1) can significantly lower your total project cost and simplify logistics, outweighing the higher management friction. This assumes you’ve done your due diligence (NNN agreement, pilot run).

-

Characteristics: You need 50,000+ pieces of a stable, mature product. Cost is the primary driver, and you have a predictable 6-8 week lead time window in your production schedule.

-

Decision: Overseas Manufacturing (China).

-

Reasoning: This is the ideal scenario for maximizing the cost benefits of global sourcing. The scale, labor advantages, and ecosystem efficiencies in China will provide the lowest possible TCO. The high volume justifies the robust quality control and logistics systems required to manage it effectively.

- Characteristics: The part is for aerospace, defense (requiring ITAR compliance), or a critical medical device. A failure is not an option, and the component is mission-critical.

- Decision: Must Use Local Manufacturing.

- Reasoning: This is a non-negotiable risk and compliance decision. The need for a secure, transparent, and auditable supply chain, along with regulatory compliance (like ITAR), completely overrides any potential cost savings.

Part Five: Conclusion

Why a “Hybrid” Sourcing Strategy Is the Winning Move

The most successful purchasing managers and CTOs we know have moved past the “local vs. overseas” debate. They know the truly strategic answer isn’t choosing one ou the other. It’s about intelligently using both.

The era of placing 100% of your manufacturing eggs in one basket is over. Geopolitical shifts and supply chain disruptions have made that strategy far too risky. This has given rise to the “China + 1” strategy—a model focused on building resilience. This isn’t just a buzzword; it’s a practical way to hedge your risks. This might involve:

- Nearshoring: Using a supplier in a country like Mexico to take advantage of zero tariffs (under USMCA) and drastically shorter land-based lead times. This gives you a cost-effective, responsive alternative without the overseas shipping and political risks.

- A Hybrid Model: Building a supply chain that uses the best of both worlds.

Your final sourcing framework should look less like a decision and more like a strategy:

- Use Local US Suppliers for what they do best: Speed and Security. This is your default for all prototypage rapide, IP-sensitive components, and mission-critical parts.

- Use Vetted “Elite” Overseas Suppliers for what they do best: Scale and Ecosystem. This is your solution for high-volume, mature products where you can leverage their massive capacity and integrated post-processing to achieve the lowest possible TCO.

By adopting this flexible, hybrid approach to your local vs. overseas (China) CNC machining decisions, you move your role from a simple cost-cutter to a strategic manager of a resilient, global supply chain.

Are you currently evaluating the TCO for your next CNC part?

Stop trying to calculate the endless variables on your own. Let our team help.

Téléchargez votre fichier CAO dès aujourd'hui. Our engineering team will provide you with a comprehensive DFM (conception pour la fabrication) analysis and a transparent “Local vs. Overseas” TCO comparison report within 24 hours—helping you make a confident, risk-free sourcing decision.

Prêt à construire une chaîne d'approvisionnement résiliente ?

You have the framework. Now, partner with an expert who can execute. Zenithin combines elite overseas quality with rigorous risk management to build the robust supply chain you need.

Références et notes

[1] Section 301 Tariffs: This refers to the specific tariffs imposed by the U.S. Trade Representative (USTR) on goods from China. The 25% rate is a key variable in any TCO calculation for Chinese-sourced goods.

[2] Dan Harris (China Law Blog): An expert on Chinese law cited for his analysis of NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreements, which are considered essential for protecting IP in China, as standard U.S. NDAs are often unenforceable.

[3] AQL (Acceptable Quality Limit): This is a statistical method used for quality control, defined by standards like ISO 2859-1. It determines the maximum number of defective units acceptable in a batch before the entire lot is rejected.