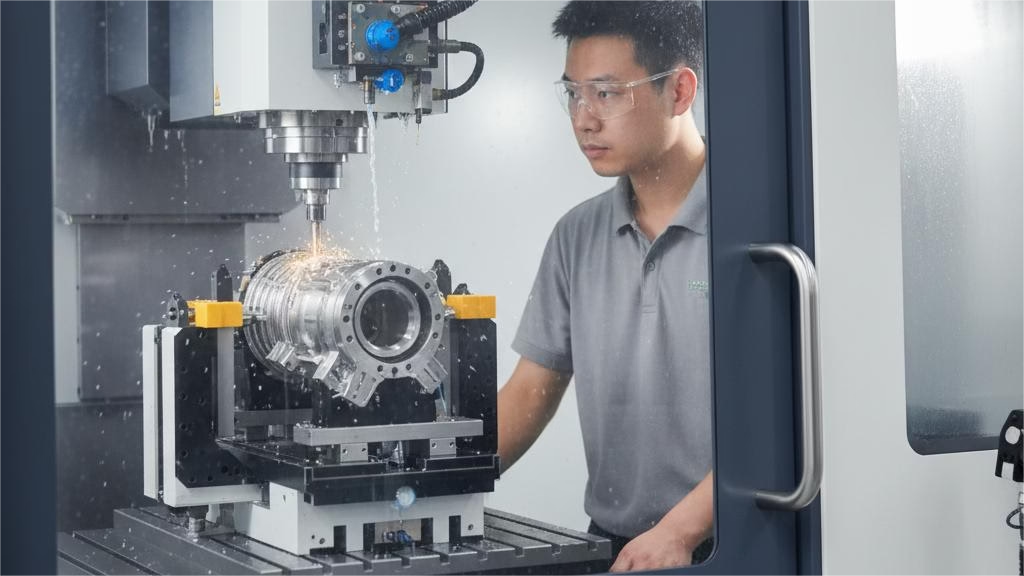

Deje de permitir que los fallos en el amarre de piezas conviertan sus piezas de alto valor en costosa chatarra. Esta es la guía definitiva para dominar el amarre de 5 ejes, que proporciona un sistema probado paso a paso para conseguir resultados impecables en piezas de alta tolerancia. Le proporcionamos las estrategias exactas para sujetar con seguridad incluso las geometrías más difíciles, garantizando siempre el éxito en la primera pasada.

El dominio del amarre de 5 ejes para geometrías complejas requiere una estrategia de "fijación primero" en la que el diseño de la fijación se planifica antes que las trayectorias de las herramientas. Esto implica analizar la geometría de la pieza para seleccionar el mejor método de fijación, como los útiles de cola de milano para un acceso máximo o los sistemas de punto cero para configuraciones rápidas y repetibles, al tiempo que se gestionan con precisión las fuerzas de fijación para evitar la deformación de la pieza y garantizar una alta tolerancia.

Ahora ya conoce los principios básicos de una estrategia de fijación eficaz. Siga leyendo para descubrir los mapas de procesos detallados, las herramientas de toma de decisiones y las técnicas avanzadas que los ingenieros de élite utilizan para superar sus retos de mecanizado más difíciles.

Por qué su estrategia de fijación es su estrategia empresarial

Cuando propone invertir en un nuevo sistema de sujeción de piezas, ¿cuál es la primera ventaja que menciona? Si es como la mayoría de los ingenieros, probablemente empiece con "reducirá los tiempos de preparación".

Aunque es cierto, es como decir que un motor de alto rendimiento sirve para "hacer girar las ruedas". Infravalora enormemente el valor real.

La realidad es que su estrategia de portapiezas no es sólo una elección técnica; es una decisión empresarial fundamental que dicta la rentabilidad, la posición en el mercado y el potencial de crecimiento de su taller.

Peter Zelinski, redactor jefe de Taller mecánico moderno...lleva mucho tiempo defendiendo esta idea. Sostiene que el objetivo del mecanizado en 5 ejes es lograr una producción "hecha en uno" y, para ello, el elemento estratégico central es el portapiezas.

Hay que pasar de preguntarse "¿Cómo sujeto esta pieza?" a "¿Cómo diseño un proceso? empezando por el portapiezasque garantice la finalización de una sola instalación?"

Su capacidad para mecanizar piezas complejas en nuestras máquinas de 5 ejes se ve comprometida si el útil bloquea el acceso a la herramienta y obliga a realizar múltiples ajustes que requieren mucho tiempo.

Hablemos de números. Una máquina de 5 ejes de gama alta puede tener un coste de funcionamiento por hora de entre 1.000 y 1.000 euros. $150 a $400. Cada minuto que ese husillo no está cortando metal, usted está perdiendo dinero. Cuando una configuración compleja lleva horas, la sangría económica es considerable.

Por eso hay que mirar más allá del precio de compra de un accesorio y considerar la Coste total de la sujeción (TCW). Este coste más real incluye la inversión inicial más los costes continuos del tiempo de preparación y, lo que es más importante, el devastador impacto financiero de las piezas desechadas.

Un solo componente aeroespacial desechado puede representar fácilmente una pérdida de más de 1.000 millones de euros. $10,000 si se tiene en cuenta el material, el tiempo de máquina, la mano de obra y las herramientas.

Aquí es donde reside la clave: dominar el mecanizado complejo no sólo mejora la eficacia, sino que transforma su modelo de negocio. Le permite escapar de la guerra de precios y márgenes de los trabajos sencillos de 3 ejes.

Cuando un cliente potencial le trae una pieza tan compleja que sus competidores tienen que "no presupuestarla", usted ya no compite en precio. Compite en capacidad. Esto le permite conseguir contratos de mayor margen y labrarse una reputación de especialista.

Además, esta experiencia le permite relacionarse con sus clientes a un nivel mucho más profundo.

Puede dejar de ser un simple proveedor y convertirse en un auténtico socio fabricanteEl diseño para la fabricación (DfM) proporciona información muy valiosa que ahorra tiempo y dinero a sus clientes.

Este modelo de asociación estratégica es la forma de construir un negocio potente y sostenible.

El método de planificación de procesos en cuatro pasos "Fixture-First

Adoptar la mentalidad "Fixture-First" es la parte estratégica. Ahora, pongámonos tácticos. ¿Cómo aplicar esta filosofía a la próxima pieza compleja que llegue a su mesa?

Necesita un proceso repetible, un plan para el éxito. Este es nuestro método de cuatro pasos para planificar un proceso centrado en la fijación.

Leer el modelo 3D con un "ojo de fijación"

Antes de pensar siquiera en las trayectorias de las herramientas, es necesario analizar la geometría de la pieza desde el punto de vista del portapiezas, un proceso que es un componente esencial de cualquier proyecto de mecanizado. Guía completa de DFM en 5 ejes.

Esto significa mirar más allá de las superficies acabadas e identificar las características que permitirán una instalación segura y estable. Hágase estas preguntas fundamentales:

-

¿Dónde están las mejores superficies de sujeción? Busque zonas gruesas y estables como bridas o secciones sólidas que puedan soportar la presión de apriete sin distorsión.

-

¿Cuáles son los puntos de referencia críticos y las tolerancias? Su Dimensionado geométrico y tolerancias (GD&T) las llamadas son su mapa. Su fijación debe localizar la pieza en sus puntos de referencia primarios y no debe aplicar fuerza de forma que pueda influir en una medición de tolerancia crítica.

-

¿Dónde están los riesgos? Identifique las paredes finas, los elementos delicados o las zonas de difícil acceso. Estas son las zonas en las que la fijación debe proporcionar apoyo, no tensión.

Material de equilibrado y presión de apriete

Para cualquier maquinista, el enemigo no es la geometría en sí, sino las fuerzas invisibles en juego, tanto la fuerza de sujeción como la fuerza de corte.

Lo aprendimos por las malas en una carcasa de aluminio aeroespacial de paredes finas. La sujetamos de forma convencional en un tornillo de banco potente y dejamos que funcionaran nuestras sendas de desbaste de alta eficacia. La pieza salía perfecta de la máquina. Pero la MMC nos contó otra historia.

La presión de apriete había doblado hacia dentro las delgadas paredes y la tensión de los fuertes cortes había deformado la base. Era una pérdida total.

Este costoso fracaso nos enseñó una lección vital: para piezas delicadas, el objetivo no es la máxima fuerza de apriete, sino la mínima fuerza distribuida en la mayor superficie posible.

Aquí es donde entran en juego los principios de la ingeniería. Una buena regla general es "Regla 5:1"Para un elemento sin soporte, su longitud no debe ser superior a cinco veces su diámetro o grosor. Si la longitud es mayor, la vibración y la flexión son inevitables.

Para esa carcasa de aluminio, nuestra solución fue una fijación personalizada que soportaba la pieza desde su brida base más resistente, utilizando múltiples abrazaderas de baja presión. Esto se combinó con una estrategia de mecanizado de alta velocidad que utilizaba cortes más pequeños y rápidos para reducir las fuerzas de corte. ¿Cuál es la clave? La estrategia de sujeción de piezas y la estrategia de CAM deben diseñarse como un sistema integrado.

Asegurar la victoria con la primera operación (Op 1)

En el mecanizado de 5 ejes, la primera preparación lo es todo. La operación 1 no consiste solo en retirar material, sino en crear una base perfecta, estable y repetible para todas las operaciones posteriores.

Tanto si está mecanizando una cola de milano, orificios de precisión para un sistema de punto cero o superficies paralelas limpias para un tornillo de banco, esta primera operación establece el "cero" para todo el proceso.

Si lo hace bien, todos los pasos siguientes se construirán sobre una base sólida. Si lo haces mal, estarás persiguiendo errores e incoherencias durante todo el proceso.

Integrar la fijación en la simulación CAM

Un diseño de fijación perfecto puede quedar inutilizado por una simple colisión. En una ocasión, un joven y brillante ingeniero diseñó una fijación personalizada de aspecto impecable para un complejo implante médico de titanio. Era una obra de arte que sujetaba la pieza con una rigidez increíble.

¿El problema? Era que demasiado bueno. Cubría la pieza de forma tan eficaz que nuestra máquina de 5 ejes no podía alcanzar determinadas características sin utilizar herramientas peligrosamente largas y finas. El resultado fue una vibración extrema de la herramienta, un acabado superficial terrible y, finalmente, una herramienta rota que desguazó la pieza.

Esta experiencia consolidó una norma no negociable en nuestro proceso: realice siempre una simulación completa de la máquina con todos los componentes incluidos. Esto significa que su entorno CAM debe disponer de modelos precisos de la máquina, el husillo, el portaherramientas, la herramienta de corte, la fijación y la pieza de trabajo.

Lo que parece claro a sus ojos puede ser una trayectoria de colisión catastrófica en todo el rango de movimiento de la máquina. Este ensayo virtual es su póliza de seguro definitiva contra errores costosos.

Combine su pieza compleja con el mejor "arsenal"

Una vez establecido el marco estratégico, hay que elegir las herramientas. El mundo de los portapiezas de 5 ejes es muy amplio y elegir el sistema adecuado puede resultar abrumador.

Para simplificarlo, piense que no se trata de una selección aleatoria, sino de una decisión calculada en función de su misión específica. Hemos desarrollado una "Matriz de decisiones" que le ayudará a elegir la tecnología adecuada para su trabajo.

No se trata de un gráfico físico, sino de un modelo mental. En un eje están los requisitos de la pieza: ¿Cuál es la complejidad de la geometría? ¿Cuán estrictas son las tolerancias? ¿Cuál es el tamaño del lote? ¿Qué rigidez debe tener la configuración? En el otro eje, tiene su arsenal de soluciones de sujeción de piezas.

Cola de milano vs. tornillo de banco autocentrante

Para muchos trabajos, su elección principal se reducirá a dos titanes de la sujeción de piezas: el útil de cola de milano y el tornillo de banco autocentrante de alta precisión.

A fijación de cola de milano es el campeón de la accesibilidad. Al sujetar la pieza en una pequeña cola de milano premecanizada, proporciona un acceso increíble a cinco lados completos de la pieza. Esto es ideal para formas complejas y orgánicas en las que se necesita la máxima holgura de la herramienta.

A tornillo de banco autocentrante, en cambio, es un maestro de la precisión y la velocidad para piezas más prismáticas. Sujeta la pieza de trabajo por dos lados, centrándola automáticamente. Esto es excelente para trabajos repetitivos en los que la ubicación constante es clave.

La contrapartida es un acceso ligeramente reducido en comparación con una cola de milano, pero para la pieza adecuada, su velocidad y precisión son inigualables.

Sistemas de punto cero

Ahora, hablemos de una tecnología que no sólo mantiene una parte, sino que revoluciona todo su flujo de trabajo: el sistema de paletas de punto cero.

Hemos experimentado esta transformación de primera mano. Teníamos un trabajo recurrente que, aunque no era excesivamente complejo, requería una hora y media de minuciosa configuración y alineación manual de cada pieza. Nuestra máquina de varios millones de dólares permanecía inactiva durante ese tiempo, y nuestro maquinista más cualificado estaba atado a una tarea repetitiva.

Tras calcular el asombroso coste de este tiempo de inactividad de la máquina, invertimos en un sistema de punto cero. Los resultados fueron asombrosos. Los 90 minutos de preparación se redujeron a menos de 10 minutos.

Pero la verdadera ventaja no fue sólo el tiempo ahorrado, sino la completa reestructuración de nuestro proceso. Creamos una estación de preparación fuera de línea en la que el siguiente trabajo se fijaba y estaba listo mientras la máquina seguía funcionando.

En John Zaya, jefe de producto de Jergens Workholding SolutionsEl objetivo es transformar la máquina de una estación de preparación a tiempo parcial en un activo de producción a tiempo completo. Este sistema nos permitió hacer exactamente eso, liberando a nuestros mejores talentos para que se centraran en la mejora de procesos y en I+D". Un sistema de punto cero de alta calidad puede ofrecer una precisión de posicionamiento repetible de ≤ 0,005 mm (5 micras)Así se asegurará de que aprovecha, y no desperdicia, la precisión de su máquina.

¿Preparado para mecanizar lo imposible?

Nuestros avanzados servicios de mecanizado CNC de 5 ejes hacen realidad sus diseños más complejos. Vea cómo nuestra experiencia en componentes de alta tolerancia puede elevar su próximo proyecto.

Cuatro técnicas avanzadas para un mecanizado sin defectos

Ha seleccionado la fijación adecuada y ha planificado su proceso. Ahora fabrica piezas buenas. Pero para un verdadero ingeniero de fabricación, "bueno" nunca es suficiente.

Se busca la perfección, un proceso tan estable y predecible que los defectos se conviertan en una anomalía estadística. Aquí es donde se va más allá de los fundamentos y se entra en el terreno del control avanzado de procesos. He aquí cuatro técnicas que distinguen a los grandes talleres de los meramente buenos.

| Técnica | Problema central | Enfoque de la solución | Beneficio clave |

|---|---|---|---|

| Gestión precisa de la fuerza | Fuerza de sujeción incoherente | Utilice llaves dinamométricas; aplique una presión baja distribuida | Evita la deformación de las piezas |

| Supresión activa de vibraciones | Vibración de la herramienta de corte | Optimizar la configuración de la CdG; utilizar herramientas cortas | Mejora el acabado superficial |

| Inteligencia en proceso | Detección tardía de defectos | Utilice sondas en la máquina para obtener información en tiempo real | Permite una fabricación adaptable |

| Control de estabilidad térmica | Expansión de la pieza inducida por el calor | Diseñar pausas térmicas; programar pausas de refrigeración | Mantiene la precisión micrométrica |

- De la "sujeción" a la "gestión precisa de la fuerza"

Deje de pensar en el apriete como algo que "aprieta". Empiece a pensar en ello como una entrada controlada con precisión a su sistema. Más del 85% de los defectos de mecanizado causados por vibraciones se deben a una fuerza de apriete incoherente o inadecuada.

¿La solución? Cuantificarlo. Utilice una llave dinamométrica calibrada para cada sujeción manual. Este sencillo paso le permite pasar de la "sensación" subjetiva a los datos objetivos, garantizando que cada pieza se sujete exactamente con la misma presión, en todo momento.

En el caso de piezas delicadas y de paredes finas, esto se traduce en una estrategia de "baja presión distribuida", es decir, el uso de múltiples puntos de contacto con una fuerza mínima y controlada para fijar la pieza sin introducir distorsiones.

- De "aceptar" a "suprimir activamente" las vibraciones

Las vibraciones son enemigas de los acabados superficiales finos y las tolerancias estrictas. Aunque algunas vibraciones son inevitables, no tiene por qué ser una víctima pasiva. Diseñe activamente su configuración para suprimirlas.

Esto significa optimizar el centro de gravedad de la pieza dentro de la fijación, utilizando las herramientas de corte y los soportes más cortos posibles y, en casos avanzados, incorporando materiales o dispositivos especializados de amortiguación de vibraciones en el diseño de la fijación. Se trata de diseñar una fijación que sea inherentemente estable y absorba, en lugar de amplificar, la energía del proceso de corte.

- De la "inspección post mortem" a la "inteligencia en proceso"

¿Por qué esperar a que una pieza esté acabada para saber si es buena? Los talleres más avanzados construyen control de calidad directamente en el proceso de mecanizado.

Utilizando un sistema de inspección en máquina (como una sonda Renishaw)Puede programar la máquina para que mida automáticamente las características críticas en las fases clave. Por ejemplo, tras una pasada de desbaste intensa, la máquina puede sondear la pieza para detectar cualquier desviación mínima causada por la liberación de tensiones.

A continuación, puede ajustar automáticamente el sistema de coordenadas para las pasadas de acabado. No se trata sólo de inspección, sino de fabricación adaptativa. Se trata de detectar y corregir pequeños errores antes de que se conviertan en fallos fatales.

- Conquistar la "mano invisible" de la estabilidad térmica

En los trabajos de ultraprecisión en los que las tolerancias se miden en micras, el mayor enemigo puede ser invisible: el calor. Tanto el husillo de la máquina como el propio proceso de corte generan calor, lo que puede hacer que la pieza de trabajo y la fijación se dilaten una cantidad ínfima, pero crítica.

Unos pocos grados de cambio de temperatura pueden marcar la diferencia entre una pieza conforme a las especificaciones y otra que no lo está. Para evitarlo, diseñe dispositivos con rotura de puente térmico, utilice materiales estables a la temperatura y programe pausas estratégicas en el ciclo para permitir que la pieza se normalice antes de los últimos cortes de acabado. Este es el nivel de detalle necesario para dominar el arte del mecanizado de alta tolerancia.

Conclusiones: Su instalación, el futuro de su fábrica

Hemos pasado de la importancia estratégica del amarre de piezas a los detalles micrométricos del control de procesos. Si hay algo que debemos aprender es lo siguiente: la adopción de una "Fixture-First" es el paso más poderoso que puede dar para obtener un control absoluto de sus complejos procesos de mecanizado.

Es la forma de satisfacer su impulso profesional más profundo: transformar la incertidumbre en excelencia predecible y repetible.

Pero, ¿hacia dónde se dirige todo esto? El futuro de los dispositivos de sujeción de piezas no consiste sólo en mejorar el acero o reforzar las abrazaderas, sino también en la inteligencia. La próxima generación de dispositivos no se limitará a ser un socio pasivo y silencioso.

Serán nodos activos y basados en datos de un ecosistema de fabricación inteligente. Imagine un tornillo de banco con sensores integrados capaces de detectar la aparición de vibraciones e indicar a la máquina que ajuste sus parámetros de corte en tiempo real. Esto no es ciencia ficción; es la dirección hacia la que se dirige nuestra industria.

Las decisiones que tome hoy para adoptar un sistema modular y adaptable Portapiezas de 5 ejes están sentando las bases de la competitividad de su fábrica en la era de las fábricas inteligentes.

Entendemos que cada pieza compleja presenta un rompecabezas único. Nuestra experiencia no se aprendió en los libros de texto; se forjó resolviendo problemas de ingeniería reales, costosos y desafiantes, como los que usted afronta.

Compartimos nuestras experiencias -incluidos nuestros fracasos- porque creemos que la transparencia es la única forma de generar una confianza duradera.

¿Está listo para iniciar su próximo proyecto de alta precisión?

Ya ha visto el nivel de detalle que aplicamos a nuestros procesos. Ahora, deje que nuestros expertos apliquen esa misma precisión a sus componentes más exigentes.

Referencias y notas

[1] Comentario de un experto sobre la estrategia de 5 ejes: Las opiniones atribuidas a Peter Zelinski se sintetizan a partir de su extensa labor editorial en Modern Machine Shop, que subraya sistemáticamente la importancia estratégica del mecanizado "hecho en uno" y el papel fundamental del portapiezas avanzado para conseguirlo.

[2] Precisión del sistema de punto cero: La precisión de posicionamiento repetible de ≤ 0,005 mm es una especificación de rendimiento estándar citada por los principales fabricantes de sistemas de sujeción de punto cero de alta calidad, como Schunk, Jergens y Erowa. Esta cifra representa la capacidad del sistema para reubicar un palé o accesorio exactamente en la misma posición de forma constante.

[3] Estudio de un caso real: El caso de Joe Torrente y Pro-Precision Machine, Inc. apareció en un estudio de caso público de 5th Axis Workholding, que ilustra el impacto empresarial directo de la adopción de fijación especializada de 5 ejes para ampliar las capacidades de mecanizado.