CNC Turning Services

Bring your most ambitious designs for cylindrical parts to life. Our precision turning services empower you to achieve exceptional accuracy and superior surface finishes for everything from custom shafts and pins to complex valve bodies.

Ensure perfect concentricity and tight tolerances, guaranteeing your components will function flawlessly and reliably in their final application.

- Tight Tolerance Guaranteed

- Complex Geometry Capability

- Rapid Process Planning & Production

Mastering Precision Turning: Process & Benefits

CNC turning is a fundamental process for creating high-precision cylindrical parts with exceptional surface finishes. Understand our expert approach to turning and discover the key benefits it brings to your project.

Our Approach to Precision Turning

At its core, CNC turning involves shaping a rotating workpiece with a stationary cutting tool.

For us, it’s the science of achieving perfect concentricity, fine surface finishes, and complex profiles on all cylindrical and round components, from simple pins to intricate valve bodies.

-

High Concentricity & Accuracy Ideal for creating parts with exceptional roundness and precise diameters.

-

Superior Surface Finishes The turning process naturally produces very smooth surface finishes, which can be further improved with grinding.

-

Cost-Effective for Round Parts For cylindrical parts, turning is often the fastest and most cost-effective manufacturing method.

Our CNC Turning Capabilities at a Glanc

With a massive fleet of over 40 CNC lathes, we have the capacity and precision to handle your project, whether it’s for a few prototypes or tens of thousands of parts.

|

Feature

|

Zenithin's Specification

|

|---|---|

|

Equipment |

Over 40 CNC Lathes (incl. 20 Swiss-type & 23 Turret Lathes) 2 |

|

Max Part Diameter |

Up to Ø400 mm |

|

Max Part Length |

Up to 1200 mm |

|

Standard Tolerances |

ISO 2768-m (Medium/Fine) |

|

Highest Precision |

Can reach H6 (0.005mm) with grinding 3 |

|

Materials |

Stainless Steel, Steel, Aluminum, Brass, Titanium, PEEK, POM... |

|

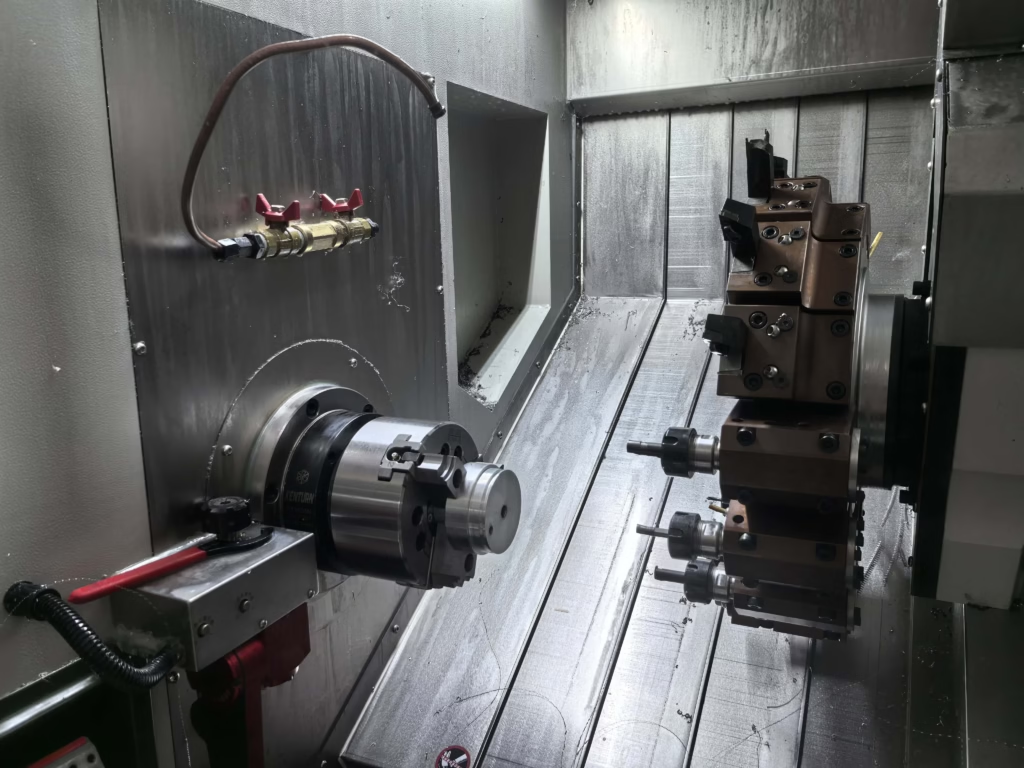

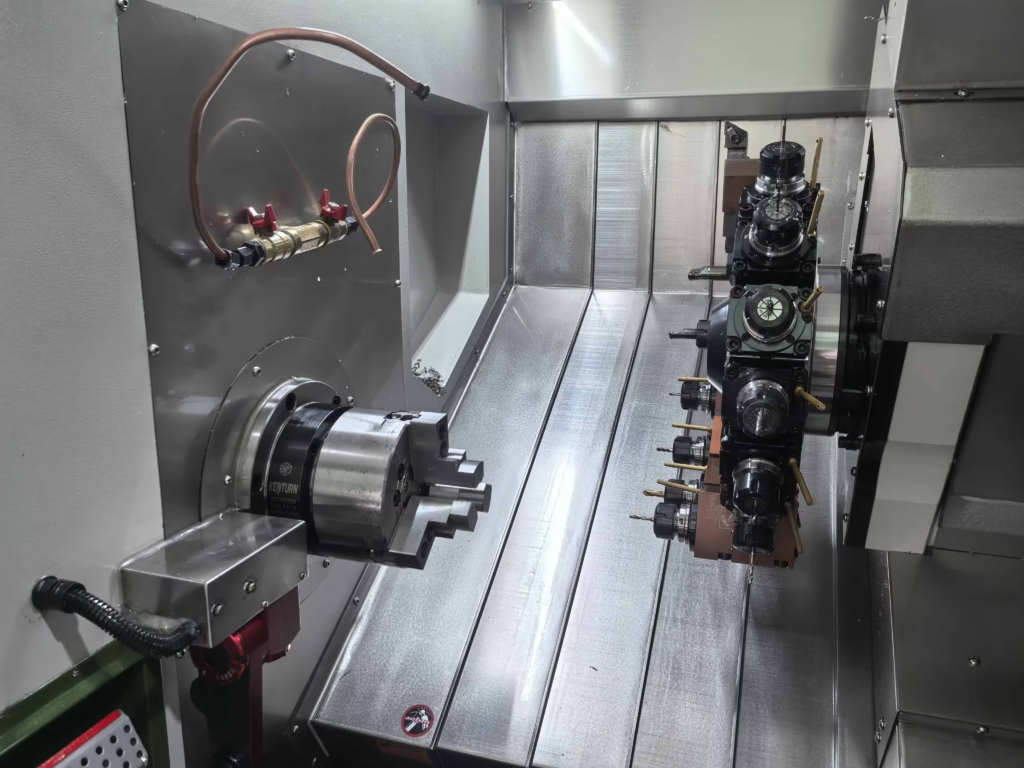

Live Tooling? |

Yes, for complex turn-mill operations. |

Our Turning Project Showcase

We believe our work speaks for itself. Below is a selection of CNC turning projects we have completed for our clients, from high-precision shafts to complex cylindrical components. Each part showcases our commitment to delivering exceptional accuracy and superior surface finishes.

-768x1024.avif)

Precision Steel Stop Collar

Machined from 45# Steel via CNC turning and milling, holding a critical geometric tolerance of 0.01mm and finished with durable chrome plating.

-768x1024.avif)

Precision Steel Stop Collar

Machined from 45# Steel via CNC turning and milling, holding a critical geometric tolerance of 0.01mm and finished with durable chrome plating.

- Phone:+1 (859) 254-6589

- Email:[email protected]

Multi-Process Steel Flange

Produced from 45# Steel using both turning and milling, this flange holds a suite of geometric tolerances (⊥/▱/◎) to 0.01mm and features a hard chrome-plated finish.

Multi-Process Steel Flange

Produced from 45# Steel using both turning and milling, this flange holds a suite of geometric tolerances (⊥/▱/◎) to 0.01mm and features a hard chrome-plated finish.

- Phone:+1 (859) 254-6589

- Email:[email protected]

-1024x891.avif)

Anodized Aluminum Connector

A complex connector machined from Aluminum 7071, utilizing turning, milling, and drilling to hold 0.01mm geometric tolerances and achieve a striking red hard-anodized finish.

-1024x891.avif)

Anodized Aluminum Connector

A complex connector machined from Aluminum 7071, utilizing turning, milling, and drilling to hold 0.01mm geometric tolerances and achieve a striking red hard-anodized finish.

- Phone:+1 (859) 254-6589

- Email:[email protected]

Impressed by Our Work? Let's Build Yours.

We are ready to apply the same precision and commitment to quality to your project. Upload your design files to get started with a free, no-obligation quote from our expert engineers.

PRECISION

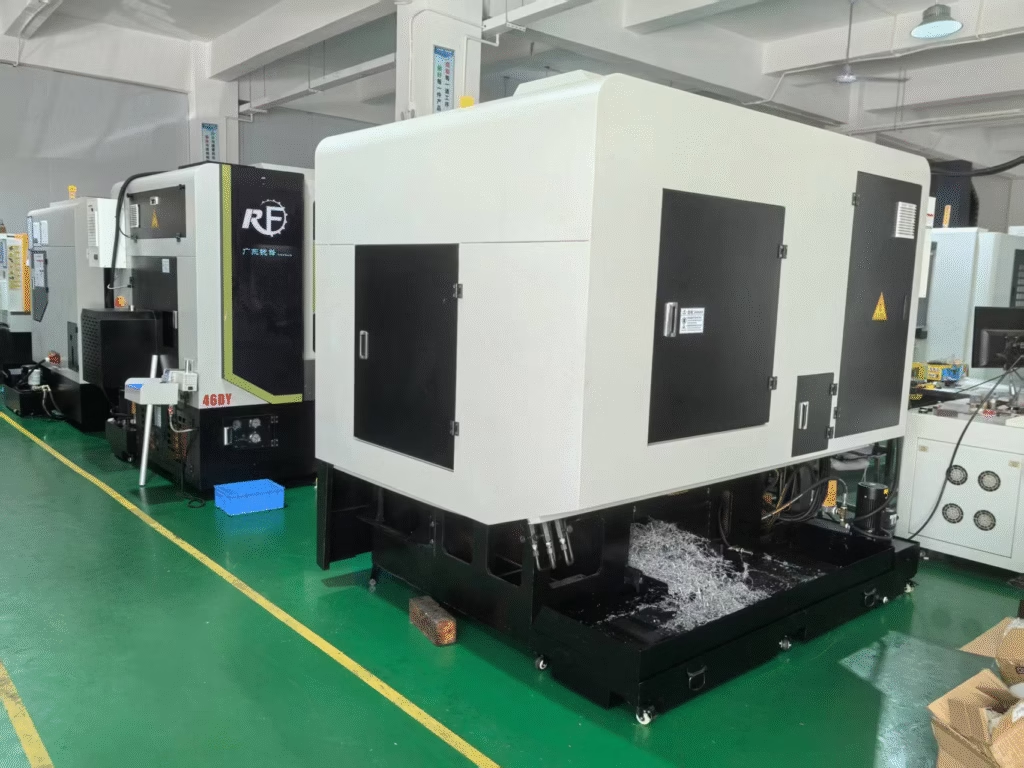

Powered by Advanced CNC Technology

Our workshop is equipped with a fleet of modern 3 and 4-axis CNC milling centers. We invest in high-quality equipment and regular maintenance to ensure consistent precision, efficiency, and reliability for every part we produce.

Harrison Hudson

CEO

Lathe equipment for turning

Harrison Hudson

CEO

Harrison Hudson

CEO

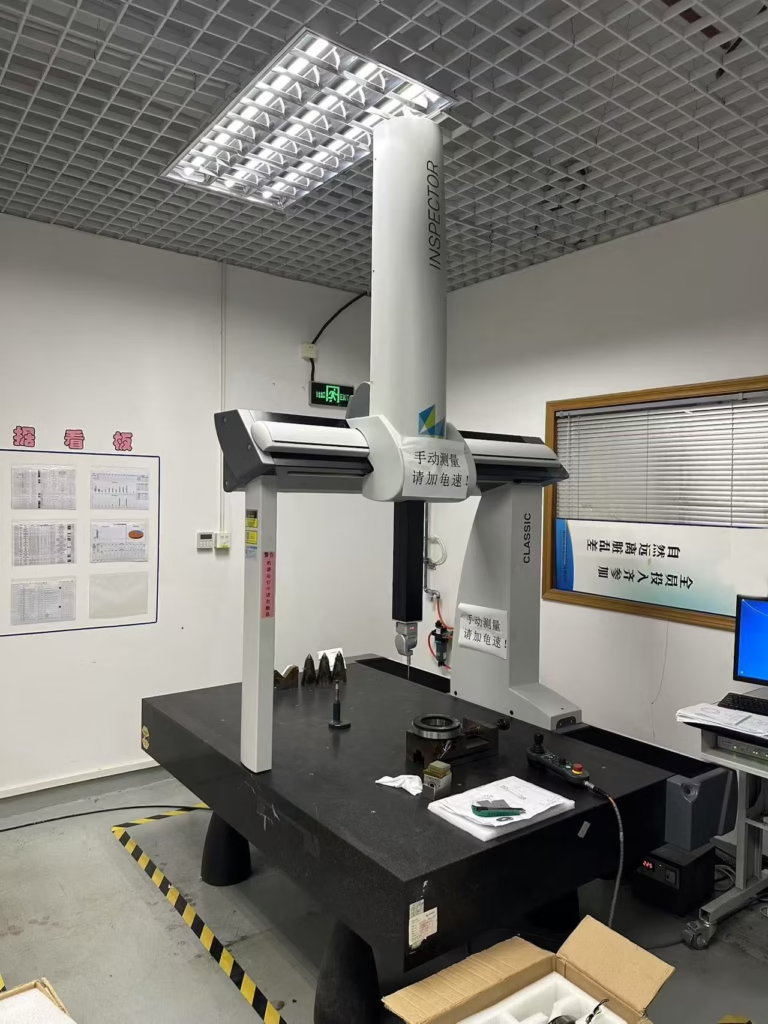

Precision, Verified.

We don’t just machine with precision; we prove it. Every turned component is subject to a rigorous quality control process, culminating in a final verification on our high-precision CMM to ensure it meets your exact specifications.

High-precision Digital Height Gauge

Three-dimensional Measuring Instrument

Three-dimensional Measuring Instrument

CNC Turning FAQ

Find answers to common questions about our turning services below. If your question isn’t listed, our engineers are ready to help.

A standard turret lathe is ideal for larger diameter parts, while a Swiss-type lathe excels at producing long, slender, and complex small-diameter parts with high accuracy.

We operate over 40 lathes, including 20 Swiss-type machines, to select the perfect process for your component.

Yes, our CNC turning centers with "live tooling" can perform secondary milling and drilling operations in a single setup. This turn-mill capability increases accuracy and reduces costs for complex parts.

While our standard tolerance is ISO 2768-m, turning is excellent for high concentricity. For critical features, we can achieve tolerances as tight as H6 (0.005mm) with secondary grinding.

Our standard as-turned finish is typically Ra 1.6 μm. Upon request, we can achieve much finer finishes, such as Ra 0.8 μm or better, through specific strategies or secondary processes.

We regularly turn a wide range of materials, including various grades of Aluminum, Stainless Steel, Brass, Steel, Titanium, and engineering plastics like PEEK and POM. We can advise on the best material for your needs.

While we support prototyping from a single part, CNC turning is most cost-effective for low-to-medium volume production runs, typically from 100 to 10,000+ pieces, due to its high efficiency.

Start Your CNC Turning Project Today

We are your dedicated partner for projects of any scale, from single prototypes to low-volume production runs.

Submit your design today to receive more than just a price—get a comprehensive quote complete with a free, expert DfM analysis to ensure your project’s success.

Take the first step today !

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.

.avif)

-scaled.avif)