Custom Aluminum Anodizing Service (Type II & Type III)

Flawless cosmetic finishes for your CNC machined parts. Our DFM-integrated process protects your critical tolerances.

- In-House CNC + Anodizing

- Expert DFM for Tolerances

- MIL-A-8625 Certified

Anodizing Solutions: Type II (Cosmetic) vs. Type III (Hardcoat)

Type II (Cosmetic & Corrosion Resistance)

The standard for cosmetic parts, enclosures, and front panels. Provides excellent corrosion resistance and a wide range of color options.

Key Spec: Forms a thin, primarily non-dimensional coating. Does not significantly alter part tolerances.

Type III (Hardcoat & Abrasion Resistance)

Engineered for high-performance functional parts. Delivers an ultra-hard, thick, abrasion-resistant surface (per MIL-A-8625).

Crucial DFM Note: Adds significant build-up (~0.002"). Requires expert tolerance compensation and masking for critical dimensions.

Anodized Aluminum Applications

Anodizing is the critical specification for aluminum parts, delivering specified corrosion resistance, abrasion resistance, and A-grade cosmetic finishes for demanding applications.

Custom Enclosures & Front Panels Services

CNC machined aluminum enclosures and panels, pre-treated with fine bead blasting, and finished with a Type II matte black anodize for A-grade cosmetic requirements.

Robotics & Industrial Automation Services

Precision CNC machining of 7075 aluminum, finished with a MIL-A-8625 Type III Hardcoat to maximize surface hardness and abrasion resistance for functional parts.

Medical Device Components Services

CNC machined 6061 aluminum parts, finished with a Type II clear anodize. This provides a non-reactive, biocompatible surface with excellent corrosion resistance for sterilization.

Audio & Consumer Electronics Services

Precision CNC milling of cosmetic-grade enclosures, pre-treated with fine bead blasting to create a uniform matte texture, and finished with a Type II black anodize.

Anodizing Capabilities: Finishes, Colors & Precision Masking

Achieving the final part specification requires control over three key variables: the pre-treatment finish (texture), the color (dye), and the precision masking strategy for protecting critical features like threads, bores, and tolerances.

Anodizing Colors & Consistency

The final color and uniformity of an anodized part are directly influenced by the base aluminum alloy (e.g., 6061 vs. 7075), the pre-treatment finish (e.g., bead blasted vs. as-machined), and the anodizing type (II or III). Standardized colors are available to meet most cosmetic and functional requirements.

Powder Coating: Our Recommended Solution

Black Anodizing (MIL-A-8625, Type II & III)

The industry standard for a clean, non-reflective matte finish. Black anodizing is the most specified color for cosmetic enclosures, front panels, and functional components. Provides a durable, deep black on most aluminum alloys.

Clear Anodizing (MIL-A-8625, Type II & III)

Also known as "natural" or "transparent" anodizing. This process adds no dye, instead revealing the pre-treated texture of the aluminum (e.g., as-machined or bead blasted). It is specified when corrosion resistance is required without altering the metallic look.

Blue, Red, Gold & Custom Colors (Type II Only)

Vibrant color anodizing options are available for Type II (cosmetic) applications. Ideal for branding, identification (e.g., red for "warning" parts), or differentiating products. Note: These organic dyes are not typically specified for Type III hardcoat due to its thickness and darker natural tone.

Crucial DFM Note: Color Consistency

Color consistency between different material batches and alloys (e.g., 6061 vs. 7075) is an inherent challenge in anodizing. For A-grade cosmetic parts, specifying the exact alloy and pre-treatment is critical.

Contact our engineering team for a DFM review to ensure consistency on high-value projects.

Pre-Treatment Finishes (Texture)

The final cosmetic appearance and light diffusion of an anodized part are determined by the mechanical pre-treatment. This step, applied after CNC machining but before anodizing, is critical for achieving a uniform, A-grade look and removing minor tool marks.

Bead Blasted Finish (Recommended for Matte)

Creates a premium, non-reflective matte finish. Ideal for A-grade cosmetic parts, as it removes minor tool marks from machining and ensures a uniform look for black anodizing.

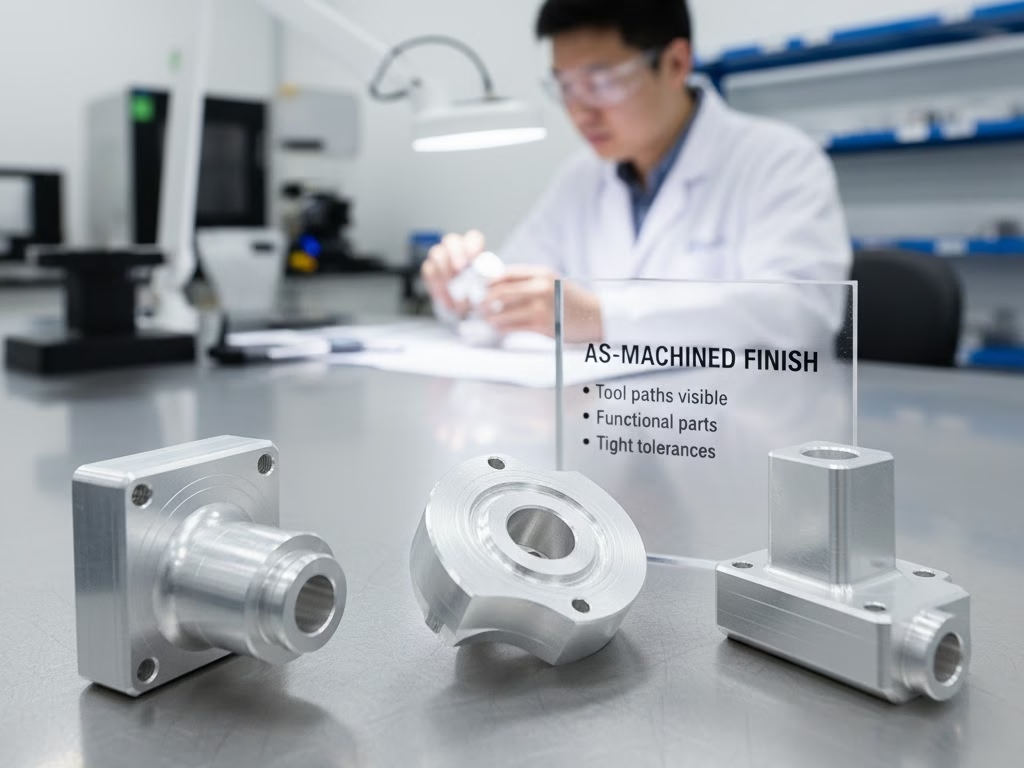

As-Machined Finish

Anodized directly after CNC machining, leaving fine tool paths visible. This finish is specified for functional, non-cosmetic parts or when retaining the tightest possible tolerances is the primary driver.

Brushed Finish (Linear Grain)

A premium decorative option that creates a uni-directional "brushed metal" grain. Typically specified for high-end audio front panels and decorative cosmetic trim.

Precision Masking for Critical Tolerances

Precision masking is an essential engineering step, not an afterthought. It is the only method to protect critical features from the dimensional build-up of Type III Hardcoat, or to maintain electrical conductivity on Type II parts.

Anodizing is an electrochemical process. Any surface left exposed will be converted. Masking involves meticulously capping, plugging, or taping features to insulate them from the chemical bath, ensuring they remain 100% true to the original machined dimensions.

Commonly Masked Features:

Critical Threads: Preventing build-up that would cause binding or galling.

Tight-Tolerance Bores & Pins: Protecting precision-fit surfaces (e.g., for press-fit bearings or dowel pins).

Electrical Contact Points: Maintaining raw aluminum surfaces for grounding (anodizing is a dielectric/insulator).

Mating Surfaces: Ensuring precision flatness and fit between assembled components.

Crucial DFM Note: Masking & Racking

A DFM review is critical to specify masking requirements. This includes defining tolerances (e.g., “Mask threads”) and also consulting on racking marks, as all parts must be electrically fixtured to the rack during the process.

The Integrated CNC + Anodizing Process

We stop you from coordinating separate vendors and risking tolerance errors. Our integrated partnership eliminates supply chain delays and the ‘blame game’ over tight dimensions, managing the entire lifecycle under one roof.

1

2

3

4

CNC Machining

High-precision CNC machining of the raw aluminum 6061 or 7075 part to exact specifications.

DFM & Masking

Expert DFM review for tolerance compensation, followed by the meticulous masking of all critical threads and bores.

Anodizing (Type II / III)

The part undergoes Type II or Type III hardcoat anodizing in our fully controlled chemical baths.

QA & Inspection

Final quality inspection, including adhesion testing and digital tolerance verification, before packaging and shipping.

Why Choose Our Integrated Process?

When your CNC vendor is your anodizing vendor, you don’t just buy a part; you buy a guaranteed outcome. Our integrated DFM and finishing process eliminates the risks that separate vendors create.

Common Questions About Anodizing (DFM & Specs)

Quick answers to the most common DFM and technical questions our engineering partners ask about anodizing aluminum.

Type II is a thin, cosmetic finish for corrosion resistance and color. Type III (Hardcoat) is a thick, ultra-hard coating for abrasion resistance.

Type III Hardcoat adds a build-up of approximately 0.001" - 0.002" per surface. Our integrated DFM process automatically compensates for this in the CNC programming.

Yes. For Type III Hardcoat, masking is essential to prevent build-up that would cause binding. We manage this for you by protecting all critical tolerances and threads.

This is the military specification that governs anodizing. It is the industry standard for ensuring coating thickness, hardness, and quality. We process all our parts to this standard.

6061-T6 is the ideal choice. It provides a consistent, deep, and uniform matte black finish. 7075 alloys can sometimes result in a slightly more variable, bronze/dark grey tone.

Racking marks are the small contact points (un-anodized) where the part is electrically fixtured. They are unavoidable, but our DFM consultation helps place them on non-cosmetic surfaces.

Get Your Anodized Aluminum Parts, Made Right.

Upload your files. Our engineers will review your design, recommend the right anodizing type (II or III), and provide a single, transparent quote for both machining and finishing.

Take the first step today !

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.