Tired of defending NRE (Non-Recurring Engineering) Costs to your purchasing manager? This guide provides the data-backed frameworks you need. Learn to confidently analyze any CNC machining quote and prove the long-term ROI of a proper NRE charge.

NRE (Non-Recurring Engineering) Costs on a CNC machining quote are one-time charges that cover the upfront engineering work required to create a stable manufacturing process. This non-recurring investment includes custom tooling (jigs and fixtures), CAM programming, and process validation (like FAI reports).

But paying NRE is only half the story. Keep reading to get the exact formulas to prove NRE’s ROI and discover the two “hidden traps” most engineers fall into (including one that could cost you thousands).

What is NRE? (Hint: It’s Not a “Fee”)

From a purchasing perspective, NRE often looks like a simple “one-time setup fee.” It’s seen as just another cost to be minimized or, ideally, eliminated.

But for us as engineers, that definition is dangerously incomplete.

A far more accurate definition of NRE is: The one-time engineering service package required to translate your technical drawing into a predictable, repeatable, and efficient mass-production process.

It’s not an fee for simply switching on the machine; it’s an investment in the manufacturing process itself.

This concept is the foundation of modern quality control. The legendary statistician W. Edwards Deming, a father of the quality revolution, taught that you cannot “inspect” quality into a part at the end of the line. By then, it’s too late.

Instead, Deming argued, you must build quality into the product in the first place.

That is precisely what a proper NRE charge represents. It is the critical, upfront engineering work to design a stable and validated process. It’s the investment that ensures part #1,000 will be identical to part #1, without relying on luck or costly mass inspections.

Where Does Your Money Go?

First, you should never accept a vague, single-line item labeled “Setup Fee.” It’s a red flag. A professional supplier who respects you as an engineering partner will have no problem providing a transparent breakdown of the NRE (Non-Recurring Engineering) costs.

When you see a charge for, say, $1,500 in NRE, it’s not an arbitrary number. It’s a calculation of the engineering time and resources needed for your specific part.

Here is what that $1,500 charge typically breaks down into:

1. CAM Programming & Simulation: $450

This isn’t just “pushing a button.” For a complex part, especially one requiring 4-axis or 5-axis machining, this cost covers a senior programmer’s time. They are digitally building the entire manufacturing process, optimizing toolpaths, and—most critically—running full simulations to detect any potential collisions.

As a plant manager, I’ve seen what happens when this step is rushed. A 10-minute simulation can prevent a $50,000 machine crash. This $450 is your insurance policy; it’s the work that guarantees your part’s complex surfaces are machined correctly and that the first part is a good part.

2. Custom Fixture Design & Fabrication: $800

This is often the largest and most important part of the NRE. When your drawing has tight positional tolerances (like concentricity or perpendicularity) between features on different faces, you cannot rely on standard machine vises. You will get inconsistent results.

This $800 covers the materials (e.g., a solid block of 6061 aluminum) and, more importantly, the engineering design and machine time to create a custom-molded “nest” for your part.

This fixture is the key to quality and efficiency. It allows the operator to lock your part in place in seconds and ensures that all critical features are machined in a single setup.

This is a classic engineering principle. The great Toyota engineer Shigeo Shingo created the SMED (Single-Minute Exchange of Die) system, which focused on converting “internal setup” (work done while the machine is stopped) into “external setup” (work done while the machine is running).

That’s exactly what this fixture does. It turns a 45-minute, high-risk manual setup (internal) into a 2-minute, reliable part-swap (external), dramatically reducing long-term cycle time and guaranteeing consistency.

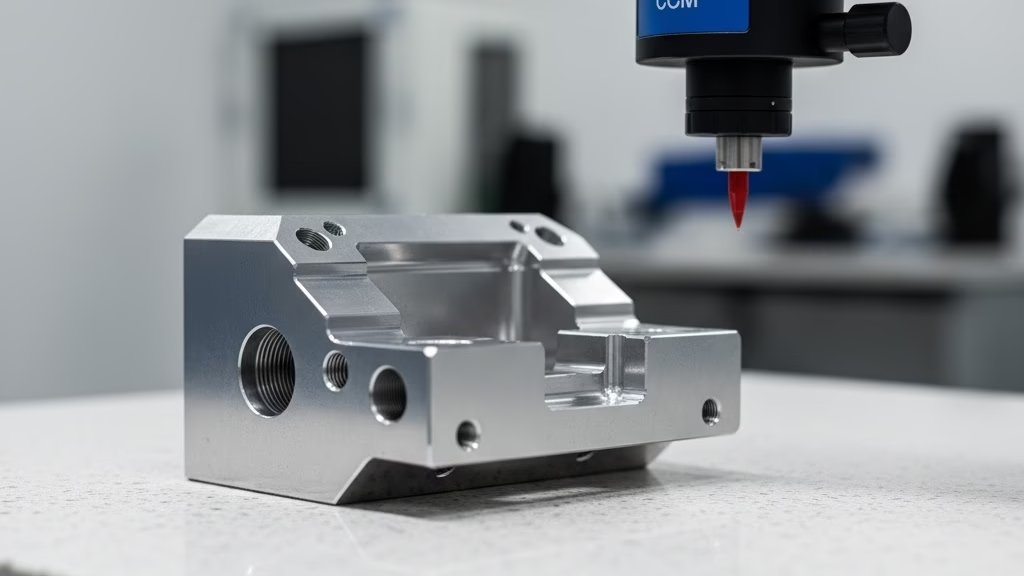

3. First Article Inspection (FAI) Report: $250

This is the formal “birth certificate” for your production process. This charge covers the quality engineer’s time and the use of expensive metrology equipment, like a Coordinate Measuring Machine (CMM).

For this, they will take the first part off the line and meticulously measure every single dimension, tolerance, and callout on your drawing. The resulting FAI report (often following the AS9102 standard) is your documentary proof that the supplier’s process is validated and capable of producing your part to spec. This is what “locks in” the process for all future orders.

When Should I Pay for NRE?

NRE (Non-Recurring Engineering) costs aren’t an “all or nothing” requirement. As an engineer, your real task is to judge the return on that investment. A professional supplier understands this. Sometimes, paying NRE is the most critical decision you can make; other times, it’s simply not necessary.

Here’s a straightforward framework to help you decide.

NRE Investment Decision Framework for Engineers

| Scenario (High-ROI) | Why You MUST Invest in NRE |

|---|---|

| Strict Tolerances | A custom fixture is the only way to reliably guarantee tight geometric tolerances (e.g., position, perpendicularity) in a production run. |

| High-Volume Production | The fixture slashes setup/cycle time. This investment is quickly paid back by a significantly lower long-term unit price. |

| Complex Geometry | Pays for essential, high-skill CAM programming time (e.g., 5-axis) to prevent errors and optimize surface finish. |

| Expensive Materials | Investing in simulation (part of NRE) prevents scrapping a $500 block of Titanium or PEEK. The insurance pays for itself. |

You can (and should) avoid NRE (Low-ROI) when:

- It’s a functional prototype. If you’re just machining a part to check form and fit, and the tolerances are loose (e.g., +/- 0.2mm), NRE is overkill.

- The part is very simple. For a basic 2.5D plate with a few holes that can be easily held in a standard machine vise, a large NRE charge is not justified.

- It’s a one-time, low-quantity order. If you know you will only ever need 1 to 10 of this part, paying a large NRE for a fixture doesn’t make financial sense. The supplier will (and should) use a slower, manual setup, and that extra time will simply be part of your higher unit cost.

Facing High NRE Costs on a Complex Part?

Complex parts often require advanced 5-axis machining, which can impact NRE. Our expertise in 5-axis programming and fixture design ensures your costs are justified and your parts are perfect, every time.

How to Justify NRE Costs to Your Purchasing Manager

This is often the most difficult part of an engineer’s job. You understand the technical necessity of the NRE (Non-Recurring Engineering) costs, but your purchasing manager’s job is to challenge every cost. When you’re in this position, you can’t just say, “We need it for the tolerances.”

You must translate the technical value into business value. Your purchasing manager thinks in terms of risk, long-term cost, and ROI.

Here are two powerful, data-driven arguments you can use.

1. Use the Break-Even Point Calculation

This is your single most effective tool. It turns a subjective argument about “quality” into a simple, objective math problem.

Let’s use a common scenario. You have two quotes for a new part:

- Quote A (Zero NRE): $0 NRE, but a $150 unit price.

- Quote B (With NRE): $5,000 NRE, but a $100 unit price.

The purchasing manager will immediately favor Quote A. Your job is to show them the crossover point.

The formula is simple:

Break-Even Point (in units) = Total NRE Cost / (Unit Price A – Unit Price B)

Let’s do the math:

$5,000 / ($150 – $100) = 100 units

Here is your script for the purchasing manager:

“I recommend we go with Quote B. While it has a $5,000 upfront NRE cost, our break-even point is only 100 units. Given our annual forecast of 500 units, this NRE investment will save the company $20,000 this year alone.”

(How? 500 units x $50/unit savings = $25,000, minus the $5,000 NRE = $20,000 total savings).

This calculation, which is the foundation of volume pricing tiers, changes the entire conversation. The NRE is no longer a “cost”—it’s an investment with a clear and massive ROI.

2. Explain the “Hidden” Value of DFM

A professional supplier’s NRE isn’t just for tooling; it’s for engineering. This includes DFM (Design for Manufacturability) analysis.

This is where the supplier’s engineers collaborate with you before any metal is cut. As Drs. Boothroyd and Dewhurst, the pioneers of DFMA, established, 70-80% of a product’s total manufacturing cost is locked in during the initial design phase.

That NRE you pay for is your last and best chance to influence that 80%.

A good supplier will analyze your design as part of the NRE service and come back with suggestions like:

- “If you can change this internal radius from 0.5mm to 1.0mm, we can use a standard endmill instead of a custom tool. This will cut your unit price by $10.”

- “We see you have two separate parts here. If we design a single, slightly more complex part, we can eliminate the assembly step and save you $15 per unit.”

This DFM analysis—this engineering collaboration—is a high-value service. It proves the supplier is thinking about your total cost, not just the part price. That’s the difference between a long-term partner and a supplier who just quotes whatever you send them.

2 “Hidden NRE Traps” 90% of Engineers Fall Into

I’ve seen where these NRE (Non-Recurring Engineering) conversations go wrong. These are the two biggest pitfalls I see engineers fall into—traps you won’t read about in a standard textbook.

Trap 1: The “Zero NRE” Illusion

A “Zero NRE” quote looks like a victory, but it’s often a major red flag.

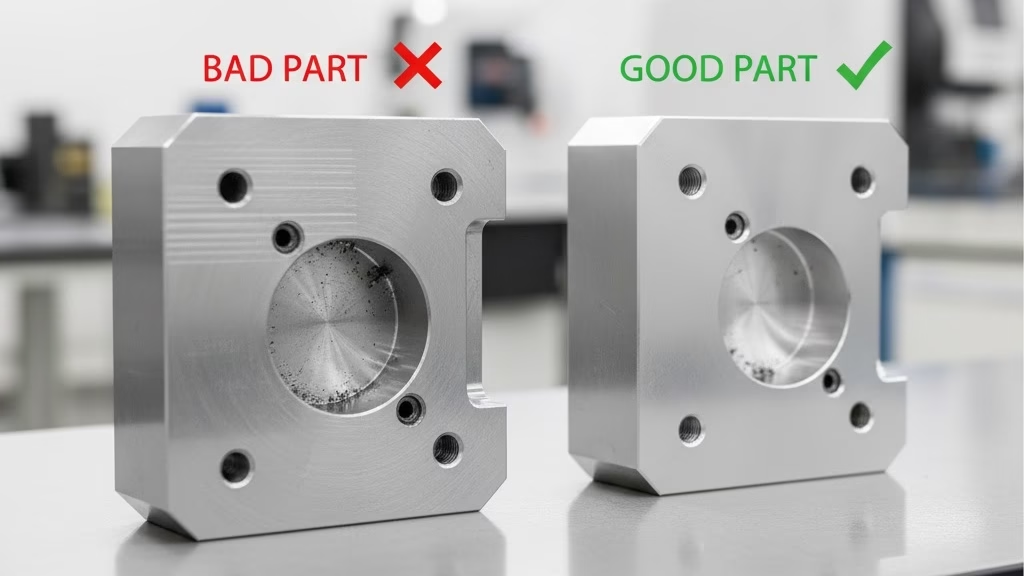

I once had a US client in the medical device field who chose a “Zero NRE” supplier to save $1,500 on a new part. The initial samples, which were manually clamped in a standard vise, passed inspection. Everyone was happy.

Three months later, the first 500-piece production order arrived. The scrap rate was over 20%.

What happened? The supplier’s “process” was just a skilled machinist making one-off parts. It wasn’t a production process. Without the custom fixture (that the $1,500 NRE would have paid for), every single setup was different. A new operator, a slight change in clamping pressure—the consistency was gone.

The lesson: The $1,500 NRE he “saved” cost his company over $15,000 in scrap, re-work, and project delays.

When you get a “Zero NRE” quote for a complex production part, you are almost always talking to one of two wrong partners:

- A Trading Company: They don’t have engineers. They are just subcontracting your part to the cheapest shop, which has no incentive to invest in a proper process.

- A Prototype-Only Shop: Their business model is speed, not repeatability. They can make you 10 good parts, but their process is not scalable.

Trap 2: The Tooling Ownership Ambiguity

This is, by far, the most dangerous and overlooked trap.

Let’s say you do everything right. You pay the $5,000 NRE. Your supplier builds a beautiful, complex fixture. The parts are perfect. A year later, you decide to move the part to a new supplier for cost or capacity reasons.

You ask your original supplier to ship you the fixture that you paid for.

And they refuse.

They will claim (and may even be legally right) that you paid for “engineering services,” not the physical “tooling asset.” The fixture, they’ll argue, is their property.

You are now “supplier-locked.” You have no choice but to pay another $5,000 NRE to your new supplier to re-create the exact same fixture.

Here is the one-sentence solution:

You must add this clause to your Purchase Order (PO) before you pay:

“All tangible assets, including but not limited to, fixtures, tools, and molds, resulting from this NRE (Non-Recurring Engineering) charge will become the property of [Your Company Name] upon payment.”

This single sentence turns your NRE from a sunk cost into a portable, tangible asset.

The Ultimate Test of a True Partner

In the end, how a supplier treats NRE (Non-Recurring Engineering) Costs is the most reliable indicator of their capability and their intentions. It’s a leading indicator of whether you will ultimately receive high-quality, consistent parts, or if you will face problems down the line.

The NRE quote is a test. It separates the “job shops” from the “manufacturing partners.”

A supplier who hides, vaguely amortizes, or “waives” the NRE for a complex part is, in effect, telling you they are compromising on the process. They are treating you like a one-time customer and are not invested in your part’s long-term quality or cost-efficiency.

A professional supplier who actively presents you with a clear, itemized NRE breakdown is doing the opposite. They are investing their own engineering resources into your part’s success. They are demonstrating that they are willing to be held accountable for the process, the quality, and the long-term price.

They are not trying to sell you a “fee.” They are inviting you into a true engineering partnership.

If you’re currently holding a quote that you don’t fully understand, send it to us. Our engineering team will provide a complimentary analysis of the NRE quote to help you identify its reasonableness, its ROI, and any hidden risks.

Translate Your Design to a Finished Part

You’ve done the engineering. Now let our team handle the complex manufacturing. At Zenithin, we turn your critical designs into precision components, with full transparency on all costs, including NRE.

References & Notes

[1] W. Edwards Deming’s Philosophy: A core concept in modern quality control, Deming’s “System of Profound Knowledge” argues that quality must be built into the process from the start, rather than being “inspected” at the end. The NRE investment directly serves this principle.

[2] SMED (Single-Minute Exchange of Die): A lean manufacturing methodology pioneered by Shigeo Shingo at Toyota. The goal is to reduce setup (changeover) time by converting “internal setup” (work done while the machine is stopped) to “external setup” (work done while it is running). A custom fixture is a classic SMED tool.

[3] AS9102 Standard: A standard used primarily in the aerospace industry that documents the First Article Inspection (FAI) process. It provides objective evidence that all engineering design and specification requirements are correctly understood, accounted for, and verified.

[4] DFMA (Design for Manufacture and Assembly): A methodology developed by Drs. Boothroyd and Dewhurst. The “70-80%” rule highlights that the vast majority of a product’s lifecycle cost is determined by its initial design, justifying the upfront engineering investment (NRE) to optimize it.