Choosing the right CNC machining supplier is one of the most critical decisions a procurement manager can make. Get it right, and your production runs smoothly; get it wrong, and you face costly delays and quality issues. This guide provides a proven, field-tested framework to help you audit and select a new supplier with total confidence.

A comprehensive audit of a CNC machining supplier involves evaluating five key areas: 1) Foundational Business Risk, including financial stability and QMS certifications like ISO 9001. 2) Technical and Engineering Capability, assessing their equipment, maintenance, and DFM skills. 3) The ‘Living’ Quality System, verifying process controls like SPC and traceability. 4) Digital Maturity, including their use of ERP/MES systems. 5) Organizational Resilience and partnership potential.

Now that you have the core framework, let’s dive into the practical steps, expert techniques, and common traps you need to avoid during your on-site visit.

The Audit Checklist for Modern Supplier Evaluation

This is where the theory ends and action begins. We’ve structured the ultimate audit checklist into five distinct modules.

This framework moves beyond simple verification and helps you assess a supplier’s foundational stability, their current capabilities, and, most importantly, their potential to grow and adapt with you. Think of this as the blueprint for your on-site visit and evaluation process.

Module 1: Foundation and Business Risk

Before you even look at a single machine, you need to assess the bedrock of the company. A supplier with a shaky foundation is a risk, no matter how appealing their piece price is.

As the renowned quality pioneer W. Edwards Deming advised, you must “End the practice of awarding business on the basis of price tag. Instead, minimize total cost.” A cheap part from a supplier who goes out of business mid-production is the most expensive part you’ll ever buy.

- Quality Management System (QMS): Do they have certifications like ISO 9001 or AS9100? Don’t just accept a copy of the certificate. Verify its authenticity online and ask for recent internal audit reports. This shows you their system is actively managed, not just a plaque on the wall.

- Financial Health: A financially unstable supplier poses a significant risk to your supply chain. You don’t need to conduct a full forensic audit, but you should inquire about their financial stability and look for signs of a healthy business that is investing in its future.

- Compliance and Reputation: Ensure they have a clean business record and understand critical compliance needs, such as ITAR for defense-related projects or robust Non-Disclosure Agreements (NDAs) to protect your intellectual property.

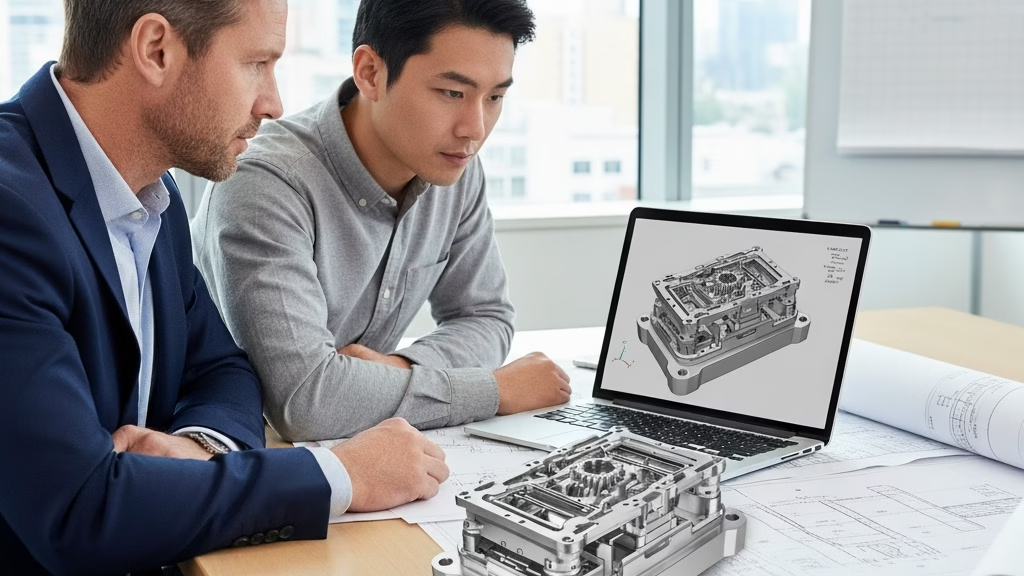

Module 2: Technical and Engineering Capability

This is where you evaluate their ability to actually make your parts to spec, consistently and efficiently. Today, this goes far beyond just counting the number of machines on the floor.

With the rise of reshoring, many new US-based shops have brand-new equipment but lack the deep process knowledge and engineering talent to run it effectively.

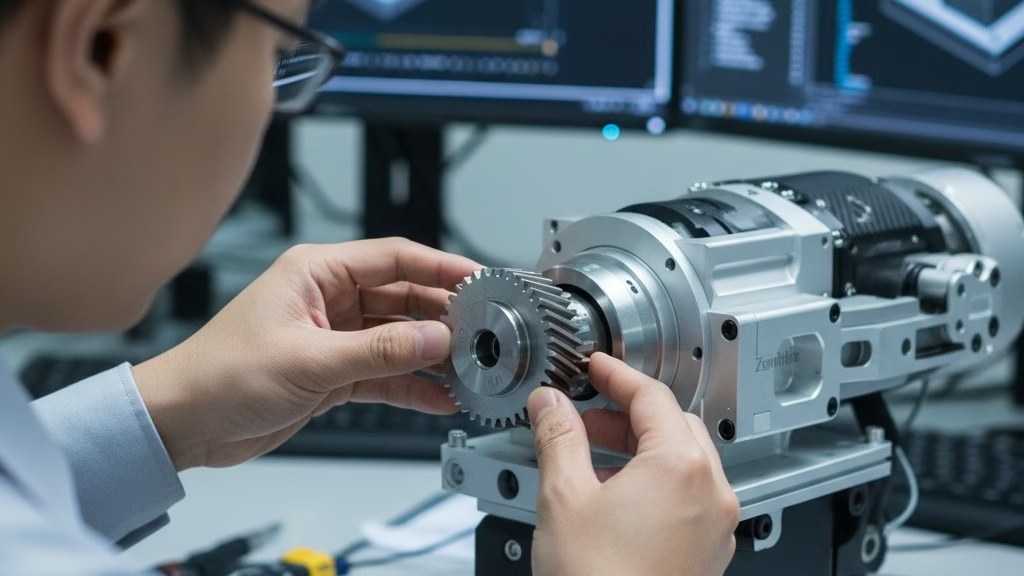

- Equipment and Maintenance: Look at their list of CNC machines, paying close attention to advanced capabilities like 5-axis machining and automated pallet changers. Crucially, ask for maintenance logs. A well-maintained older machine is often more reliable than a brand-new, poorly maintained one. Also, verify their precision inspection equipment, like Coordinate Measuring Machines (CMMs), and ask to see their calibration records.

- Engineering Team: Your goal is to assess their engineering depth. Can they provide Design for Manufacturability (DFM) feedback to help you reduce costs and improve part quality? Request to speak directly with their lead programmer or manufacturing engineer. Ask them how they would approach one of your more complex parts, for example, their strategy for deep pockets & narrow slots machining Their answer will reveal more about their true capability than any sales pitch.

- Materials and Special Processes: Do they have experience with the specific materials you require, especially challenging ones like titanium or Inconel? How do they manage their supply chain for these materials and for outside processes like heat treatment or plating? A supplier with a well-managed network of sub-tier suppliers is a valuable asset.

Module 3: The ‘Living’ Quality System

A quality certificate hanging on the wall is one thing; a quality culture that lives and breathes on the shop floor is another entirely. This is where you separate the suppliers who just meet the standard from those who are truly committed to quality.

A certificate proves they have a system, but your audit needs to prove they actually use it.

I once worked with a client sourcing medical device components. They found a supplier with a pristine ISO 13485 certificate proudly displayed. On paper, they were perfect.

But when we asked to see the full traceability records for a random production batch from the previous week, it took them two days to piece together a set of incomplete and contradictory documents.

Their quality system was an illusion, a set of binders on a shelf rather than a daily practice. This experience taught me a crucial lesson: the proof is in the execution, not the certification.

- Process Control: Don’t just ask if they have quality control. Ask for evidence of process control. Request to see Statistical Process Control (SPC) charts for a recent production run. Ask for the process capability index (Cpk) data for a critical feature on a part similar to yours. A Cpk value tells you how capable their process is of repeatedly holding tight tolerances. A supplier who actively uses this data to monitor and improve their processes is leagues ahead of one who only inspects parts at the end of the line.

- Traceability: This is non-negotiable. Pick a random job number from their production schedule and say, “Show me everything for this part.” You should be able to see the raw material certificate, all in-process inspection reports, the final inspection report, and who performed each step. If they can produce this quickly and confidently, it shows their system is robust and integrated.

- Problem Solving: A supplier who claims they’ve never had a quality issue is either inexperienced or not being truthful. A great supplier is one who can demonstrate a systematic approach to solving problems when they arise. Ask to see a recent Corrective and Preventive Action (CAPA) report or an 8D analysis for a customer complaint. You’re looking for evidence of a thorough root cause analysis, not just a quick fix. This shows they learn from their mistakes and strengthen their processes as a result.

Need a Partner You Can Trust?

Zenithin’s robust quality control and transparent processes ensure your parts are made to spec, every time. Let us handle the manufacturing complexities so you can focus on innovation.

Module 4: Digital Maturity Assessment

In today’s manufacturing environment, the machines themselves are becoming a commodity. The real competitive advantage lies in the “digital operating system” that runs the factory.

A supplier’s true efficiency and reliability are determined by their digital maturity. While your competitors are asking “What machines do you have?”, you should be asking “How do you use data?”

- Core Systems: Do they run on a modern ERP or a Manufacturing Execution System (MES)? These systems are the central nervous system of a modern factory. A supplier that uses an MES for real-time production scheduling and monitoring is making decisions based on data, not guesswork. This is a powerful indicator of their ability to manage capacity and meet delivery dates.

- Information Transparency: Ask them if they can provide a customer portal for real-time order tracking. A digitally mature supplier can give you visibility into your order’s status from start to finish, just like tracking a package. This transparency drastically reduces your own management overhead and provides invaluable peace of mind.

- Knowledge Management: How do they store critical process information? Is the knowledge of how to machine a complex part stored in the brain of a single, veteran machinist—a concept known as “tribal knowledge”—or is it captured in a centralized, digital system? A supplier that documents and standardizes its processes is protecting you from the immense risk of key personnel leaving.

Module 5: Organizational Resilience and Partnership Potential

Finally, you are not just choosing a supplier; you are choosing a partner. This requires looking beyond the technical capabilities and assessing the human element and the organization’s ability to withstand challenges and grow with you.

This is about evaluating their heart and soul.

- Talent Pipeline: The skills gap in manufacturing is real. A critical, yet often overlooked, question is: “What does your talent pipeline look like?” Ask about their apprenticeship programs, internal training, and the career path for their technicians and engineers. A company that invests in its people is building a foundation for long-term stability and is a much safer bet than one reliant on a few aging experts.

- Communication and Collaboration: During your audit, observe the dynamics. Do the engineers and quality managers speak openly and confidently, or do they defer all questions to the sales manager? I once audited a supplier where the sales director was incredibly polished, but the engineering team was silent. This is a major red flag. Your future problem-solvers are the engineers, not the salespeople. You need to be confident that you can build a strong, collaborative working relationship with their technical team.

- Culture of Continuous Improvement: Look for signs that the company is actively trying to get better. Are they investing in new technologies, training their staff, and implementing lean manufacturing principles? A supplier with a vibrant culture of improvement is a partner who will bring new ideas to the table and help you innovate, not just a vendor who executes orders.

The Auditor’s Field Manual

Having a comprehensive checklist is essential, but it’s only half the battle. The real skill lies in using it to uncover the reality behind the polished presentations and confident answers.

This is how you move from being a checker of boxes to a true assessor of capability.

Lesson 1: Trust, but Verify

The single most powerful shift you can make during an audit is to change your questions from “Do you have…?” to “Show me how…” A “yes” to the first question is easy. The second question requires proof.

- Instead of asking, “Do you have a process for handling non-conforming materials?” say, “Please walk me through your last non-conformance report. Show me the documentation, the root cause analysis, and the corrective action you implemented.”

- Instead of asking, “Do you calibrate your CMM?” say, “May I see the most recent calibration certificate and the daily verification log for this machine?”

This approach forces a move from theoretical discussion to practical demonstration. It allows you to see their systems in action, revealing whether their processes are robust daily habits or just well-written procedures in a binder.

Lesson 2: Beware of the Three Traps

Over the years, I’ve seen even experienced procurement managers fall for the same few illusions. Here’s how to spot and avoid them:

1. The ‘Perfect Sample’ Trap

A flawless sample part arrives on your desk. The finish is impeccable, and the dimensions are spot-on. It’s tempting to be impressed, but you must be skeptical. I once saw a client almost sign a major contract based on such a sample. We later discovered it was painstakingly crafted by their top machinist on their best machine, completely outside the normal production flow. It wasn’t a sample; it was a marketing piece.

Your defense: Always demand that the sample be accompanied by its First Article Inspection (FAI) report and the process capability (Cpk) data for its critical features. This data is the real proof of their ability to produce that part repeatedly, not just once.

2. The ‘Enthusiastic Sales vs. Silent Engineer’ Trap

During the audit, the salesperson is dynamic and answers every technical question flawlessly, while the engineering and quality managers remain quiet. This is a huge red flag. The salesperson won’t be the one solving your technical issues at 10 PM on a Tuesday.

Your defense: Politely bypass the salesperson. Walk over to an engineer’s workstation and ask them to explain the CAM strategy for a complex part. Ask the quality manager to walk you through their process for a new part introduction (NPI). You need to assess the capabilities of the people you will actually be working with.

3. The ‘Certificate on the Wall’ Trap

As mentioned before, a certificate only proves eligibility, not execution.

Your defense: Use the “random audit” technique. Randomly select a recent job and ask to see the complete documentation trail. The smoothness and speed with which they can produce these records will tell you everything you need to know about how deeply embedded their quality system really is.

Lesson 3: The ‘Gemba Walk’ Observation Method

“Gemba” is a Japanese term meaning “the real place.” A Gemba walk means leaving the conference room and walking the factory floor to observe the process firsthand.

Look for evidence of a well-managed environment: clear 5S markings (Sort, Set in order, Shine, Standardize, Sustain), organized tool stations, and real-time performance data displayed on information boards. A busy but orderly shop floor is a sign of a competent, well-managed organization. A chaotic one, even with impressive machines, signals underlying process weaknesses.

| Red Flag | Underlying Risk | Your Counter-Move |

|---|---|---|

| The ‘Perfect Sample’ | Inability to scale to mass production. | Request FAI and Cpk data. |

| Salesperson answers all technical questions | Lack of engineering depth or poor communication. | Engage directly with engineers and quality team. |

| ‘Certificate on the Wall’ only | Quality system is not actively used. | Randomly audit recent production records. |

| Chaotic or disorganized shop floor | Poor process control and inefficiency. | Conduct a ‘Gemba Walk’ to observe firsthand. |

From Audit to Partnership

The on-site audit is over, and you’ve selected your new supplier. It’s tempting to feel like the hard part is done, but in reality, the most critical phase is just beginning.

The success or failure of this new relationship is often determined in the first 90 days. A successful transition requires a structured approach that moves from evaluation to full integration.

Write a Report That Builds Consensus

Your first step is to translate your findings into a compelling audit report. This document isn’t just a formality; it’s your primary tool for getting buy-in from engineering, quality, and management.

Structure your report using the data from your scorecard. Present a clear, objective comparison if you evaluated multiple suppliers. Use quantitative scores to back up your recommendation, moving the decision away from subjective feelings and onto a foundation of solid evidence.

Your report should clearly outline the supplier’s strengths, identify potential risks, and propose a mitigation plan. A data-driven report doesn’t just justify your choice; it demonstrates the thoroughness of your process and builds confidence across the organization.

Implement a Structured Onboarding Plan

Don’t leave the launch of a new supplier to chance. A formal onboarding plan is crucial for a smooth start. This plan should include:

- A Kick-Off Meeting: Bring together key stakeholders from both your team and the supplier’s team. Use this meeting to align on expectations, confirm communication channels, and review the project timeline.

- Small Batch Trial Run: Before committing to full-scale production, run a small, controlled batch of parts. This allows you to validate their processes in a real-world scenario and catch any potential issues before they become major problems.

- 90-Day Performance Review: Set clear performance metrics (KPIs) from day one. Schedule a formal review at the 90-day mark to assess their performance on on-time delivery (OTD), quality (PPM), and responsiveness.

Turn Weaknesses into Opportunities

No supplier is perfect. Your audit likely uncovered some areas for improvement. Instead of viewing these as simple weaknesses, frame them as opportunities for collaborative growth.

If you noted their documentation control could be stronger, offer to share best practices from your own system. This approach transforms the dynamic from a traditional, often adversarial customer-supplier relationship into a true partnership.

By investing in your supplier’s development, you are directly investing in the long-term health and resilience of your own supply chain. This is how you build a strategic asset, not just source a part.

Conclusion: Your Choice Defines Your Supply Chain’s Future

Ultimately, a professional supplier audit is far more than a simple risk-mitigation exercise. It’s an investment in your company’s future.

The purpose isn’t just to find the cheapest price or to check off boxes on a list; it is a strategic process to identify, qualify, and build a relationship with a partner who can provide a genuine competitive advantage. In a world of increasing uncertainty, the strength and resilience of your supply chain are paramount.

Adopting this modern approach transforms your role from an order executor to a strategic architect of your company’s supply chain. You become a guardian of quality and a builder of resilient operations.

The choices you make in qualifying partners impact every aspect of the business, so make them with the confidence this thorough process provides.

Ready to Build a Resilient Supply Chain?

You’ve learned how to identify a great partner. Now, experience the difference with a supplier dedicated to precision, transparency, and collaboration.

References & Notes

[1] W. Edwards Deming: The referenced quote is a core principle from Deming’s management philosophy, which emphasizes minimizing total cost over the long term rather than simply choosing the lowest initial price. His work is foundational to modern quality control systems.

[2] Statistical Process Control (SPC): A method of quality control that employs statistical methods to monitor and control a process. It helps to ensure that the process operates efficiently, producing more specification-conforming products with less waste.