Choosing between thread milling and tapping is more than a tooling decision; it’s a critical process choice that impacts your bottom line. This guide provides a data-driven framework to help you eliminate the guesswork and make the most profitable and reliable decision for every application, every time.

The best choice between thread milling and tapping depends entirely on the application. Tapping is faster and has a lower initial tool cost, making it ideal for high-volume production in easy-to-machine materials. Thread milling offers superior process security, flexibility, and quality, making it the necessary choice for high-value parts, difficult materials, and large-diameter threads.

| Factor | Tapping | Thread Milling |

|---|---|---|

| Speed | Faster | Slower |

| Risk | High (Tool Breakage) | Very Low |

| Flexibility | Low | High |

| Hard Materials | Poor | Excellent |

Now, if you want to see the exact formula for calculating the true cost per hole (including the hidden costs of risk) and get a decision matrix that makes the right choice obvious, read on.

A Comparison of Core Process Characteristics

To make the right choice, you first need to understand the fundamental differences between these two processes. They aren’t just different tools; they operate on entirely different principles. Think of it as their core DNA.

| Characteristic | Tapping | Thread Milling |

|---|---|---|

| Machining Principle | Axial advancement, one pass | Helical interpolation, multi-pass |

| Cutting Forces | High torque, high axial force | Low radial force |

| Chip Formation | Long, stringy chips | Small, segmented chips |

| Primary Risk | Catastrophic tool breakage | Minimal; gradual tool wear |

Tapping works by driving a tool of the exact thread profile into a hole. It’s a brute-force, single-pass operation that generates immense torque and long, difficult-to-manage chips, especially in blind holes.

The biggest issue? The tap is larger than the hole it’s creating. If it binds or breaks, you have a serious problem.

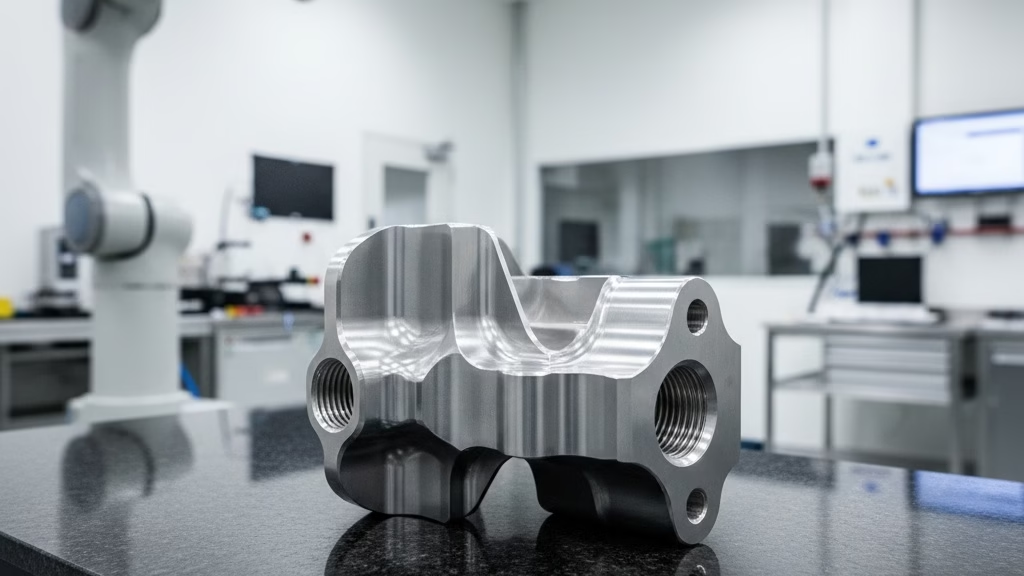

Thread milling, on the other hand, is a more finessed approach. A cutter smaller than the hole diameter moves in a circular, helical interpolation path, gradually forming the thread profile.

This creates small, easily evacuated chips and exerts low radial cutting forces, placing significantly less stress on the tool and the machine’s spindle.

This difference in process security is paramount, especially when working with high-value components. Global tooling leader Sandvik Coromant consistently emphasizes this in their technical guides.

The primary advantage of thread milling…is process security. A tap is a high-risk tool; if it breaks, the component is often scrapped. A thread mill, being a smaller diameter than the hole, presents almost zero risk of catastrophic tool breakage.

This inherent safety is why it’s often the default choice when precision and risk mitigation are the top priorities.

The 3-Minute Application Matrix

Theory is great, but you need a practical tool to make quick, reliable decisions on the shop floor. This matrix is designed to do just that.

It helps you move from guesswork to a data-driven choice in minutes. Find your application’s primary characteristics in the left-hand column and see which process is recommended.

| Decision Variable | Tapping | Thread Milling | Key Consideration |

|---|---|---|---|

| Part Value > $5,000 | 🔴 High Risk | 🟢 Highly Recommended | The cost of failure far outweighs the cost of the tool. |

| Material Hardness > 45 HRC | 🔴 High Risk | 🟢 Highly Recommended | Tool life and the simple ability to machine the material. |

| Production Volume > 10,000/month | 🟢 Highly Recommended | 🟡 Cycle Time Concern | Tapping offers the highest speed for single-hole efficiency. |

| Thread Diameter > M30 | 🔴 High Risk | 🟢 Highly Recommended | Tapping large diameters requires massive machine torque. |

| Blind Hole > 2.5x Diameter | 🟡 High Risk of Chip Packing | 🟢 Highly Recommended | Thread milling produces small chips that are easily removed. |

| Small Lot / Prototype Run | 🟡 Inflexible | 🟢 Highly Recommended | One thread mill can create multiple thread sizes and pitches. |

How to use this matrix: Simply cross-reference your specific job requirements. For instance, if you’re threading a single prototype part from Inconel with a value of $10,000, the matrix clearly points to thread milling as the only secure option.

Conversely, for a high-volume run of M6 holes in aluminum, tapping remains the most time-efficient method. This tool provides a logical starting point for your decision, allowing you to quickly justify your choice with clear, defensible criteria.

Calculating Your True Cost Per Thread

What’s the first thing you look at when comparing a tap and a thread mill? If you’re like most, it’s the price tag. A $25 tap versus a $120 thread mill seems like an easy decision.

But the initial tool price is just the tip of the iceberg. The true cost is hidden below the surface, in the variables that don’t show up on the purchase order.

To make a financially sound decision, you need to calculate the True Cost Per Thread. Here’s a model you can use:

Cost per Thread = (Machine Hour Rate × Cycle Time) + (Tool Cost / Tool Life) + (Failure Rate × Part Value)

Let’s break it down:

- Machine & Cycle Time Cost: This is straightforward. Tapping is often faster in the cut, giving it an initial advantage here.

- Tool Cost & Life: While the initial cost of a thread mill is 3x to 8x higher than a tap, its tool life can be 5x to 10x longer in difficult materials like stainless steel or titanium, often balancing this part of the equation.

- Failure & Risk Cost: This is the game-changer. This is the “hidden” cost that can destroy your profitability. For a tap, a conservative failure rate leading to a scrapped part might be 1-2%. For a thread mill, it’s less than 0.1%.

If your part is worth $5,000, a 2% failure rate adds a staggering $100 of risk cost to every single tapping operation. Suddenly, that $120 thread mill looks incredibly cheap.

I once worked with an automotive client who was convinced tapping was the king of efficiency for their high-volume aluminum brackets. Their cycle times were fantastic. Yet, their overall output never matched theoretical calculations.

After a week of data tracking, we found the culprit: the tapping machine was down an astonishing 15% of the time dealing with random issues—broken taps, inconsistent thread quality, and unpredictable tool changes.

We switched one key hole to thread milling. The cycle time per part increased by 2.5 seconds. But by the end of the week, the line’s total output had increased by 8%.

We eliminated the unplanned downtime. This proved a vital lesson: true production speed isn’t about the fastest single operation; it’s about the most stable and predictable overall process.

Deep Dive into Key Application Scenarios

While the matrix gives you a great overview, some situations demand a closer look. Let’s break down the most common and challenging scenarios you’ll face on the shop floor.

Difficult-to-Machine Materials

When you’re working with materials like hardened steels (>45 HRC), titanium alloys, or Inconels, conventional tapping ranges from difficult to impossible.

The extreme heat and cutting forces generated will destroy a tap in short order. In these cases, thread milling isn’t just a better option; it’s often the only viable option.

The lower cutting forces and superior heat dissipation of the milling process allow for predictable, high-quality threads without risking tool breakage.

Large Diameter and Deep Hole Threads

Need to machine an M30 thread? With a tap, you’d need a machine with immense spindle torque—something many smaller VMCs simply don’t have.

Thread milling requires up to 70% less torque, allowing you to create large-diameter threads on less powerful machines.

For deep holes (greater than 2.5 times the diameter), tapping becomes a gamble due to chip evacuation problems. The small, manageable chips produced by thread milling can be easily flushed out with coolant, ensuring a clean and accurate thread from top to bottom.

High-Precision and Special Threads

If your print calls for a high-precision 4H/5H fit or a special thread form like a UNJ, a standard tap won’t give you the control you need.

With thread milling, precision is programmed in. By simply adjusting the cutter’s path via CNC radius compensation, you can precisely control the pitch diameter to achieve exacting tolerances that are impossible with a fixed-size tap.

Small Batch and High-Mix Production

I once worked with a rapid prototyping shop that constantly dealt with design changes. A customer might change a thread from M10x1.5 to a fine-pitch M10x1.25.

In the past, this meant a 20-minute scramble to find the right tap, change tools, and reset. After standardizing on thread milling, that same change took 30 seconds.

The operator simply edited a single line of G-code. For any shop focused on agility, thread milling’s value isn’t just in its reliability, but in its incredible flexibility to adapt to change instantly. It transforms a physical tooling problem into a simple digital adjustment.

Building a Hybrid and Future-Ready System

The conversation around Thread Milling vs. Tapping often forces you into a false dilemma—as if you must choose one and abandon the other entirely.

The most efficient and profitable machine shops, however, operate on a higher level. They don’t just pick a tool; they build a system. The optimal strategy is often a hybrid approach where both processes are used intelligently.

Think about a complex part like an engine block. For the dozens of standard M6 and M8 coolant channel holes in cast aluminum, a high-performance forming tap is the undisputed champion of speed and cost-effectiveness.

But for the critical, high-tolerance main bearing cap threads, where failure is not an option, thread milling provides the absolute process security and quality required.

This is where you shift from a tactical tool-picker to a strategic process planner. And this strategic thinking becomes even more critical when you look to the future.

Industry 4.0 and the “Smart Process”

Tapping is essentially a “dumb process.” You command a G84 cycle and hope for the best, with little to no data feedback until it’s too late.

Thread milling, however, is a fully controlled contouring path, making it a “smart process” perfectly suited for data-driven manufacturing and Industry 4.0.

You can monitor spindle load in real-time to predict tool wear, allowing for true predictive maintenance in a “lights-out” automated environment. This level of process data and control is not just a nice-to-have; it’s a prerequisite for building the factory of the future.

De-risking Your System Amidst the Skills Gap

Experienced machinists who can “hear” when a tap is about to fail are becoming increasingly rare. Modern manufacturing must reduce its reliance on this kind of individual tribal knowledge.

Thread milling helps de-risk your entire system. Success is engineered into the CAM program and the process itself, not dependent on the feel or experience of the operator at the machine. It creates a standardized, repeatable process that anyone can execute reliably.

There is no single ‘better’ method; the choice is application-dependent. For high-volume production…a high-performance tap is still the undisputed king of productivity…However, when you encounter difficult materials…or when you need to produce a variety of thread sizes…thread milling becomes the problem solver.

Ultimately, you should stop asking, “Which tool is better?” and start asking, “In my manufacturing system, what is the correct role for each of these processes?”

Conclusion

We’ve covered a lot of ground, moving from gut feelings to a structured, data-driven approach for choosing your threading process. To make it even simpler, here is a final checklist to run through every time you face this decision.

Your Decision Checklist

- Assess the Risk First: Before you even think about the tool, calculate your risk. What is the total value of the part at the point of threading? If the cost of a single scrapped part is greater than the cost of a thread mill, your choice is already clear.

- Calculate the True Cost: Use the True Cost Per Thread formula. Don’t be swayed by the initial purchase price. Factor in tool life, machine time, and the hidden costs of failure and downtime.

- Match the Process to the Application: Refer back to the decision matrix. Is it a hard material? A large diameter? A high-volume run? Let the specific demands of the job guide your choice.

- Think System, Not Just Tool: Consider how this choice fits into your larger manufacturing strategy. Do you need the data and control for automation? Do you need the flexibility for high-mix production?

Making the right choice between Thread Milling vs. Tapping is a hallmark of a great manufacturing engineer. It shows you can balance speed with security, and tactical costs with strategic value.

By using the frameworks in this guide, you are now equipped to make decisions that are not only technically sound but also financially smart, protecting your parts, your budget, and your production schedule.

Ready to Eliminate Threading Failures?

You’ve learned the strategy. Now let our expert engineers apply it to your parts, ensuring every thread is perfect, every time. Let’s build a more reliable process together.

References & Notes

[1] True Cost Per Thread: This is a variation of the Total Cost of Ownership (TCO) model, specifically adapted for machining operations. It emphasizes quantifying risk, a factor often overlooked in traditional cost-per-part calculations.

[2] Helical Interpolation: A CNC machine capability (G-Code G02/G03 with a Z-axis value) that allows a cutting tool to move in a helical path. This is the foundational technology that enables thread milling.