Choosing between a Turn-Mill vs. a Traditional Lathe dictates your shop’s future efficiency and accuracy. Stop losing profit to secondary operations and tolerance stacking. This in-depth guide provides the definitive ROI framework and technical data engineers need to justify the move to one-hit machining.

A traditional lathe requires multiple machine setups for milling and turning, causing major delays and “tolerance stacking” accuracy errors. A Turn-Mill integrates both processes, using sub-spindles and live tooling to complete complex parts in a single setup. This one-hit machining approach drastically cuts cycle time, eliminates setup errors, and lowers cost per part.

But the analysis doesn’t stop there. We’ve compiled the critical data, ROI formulas, and hidden implementation traps (like the “programming bottleneck”) that every engineer must know before signing that PO.

Technical Showdown: Clarifying the Three “Solutions” on the Market

As an engineer, your first major risk isn’t in the ROI calculation; it’s in the RFQ. The single most expensive mistake we see clients make is fundamentally misidentifying the machines. The market intentionally blurs the lines, but your search for “Turn-Mill vs. Traditional Lathe” is actually a three-way choice. Confusing them will lead you to buy a machine that fails to solve your core problem.

Let’s clarify the options right now.

Option A: The Traditional Process (Lathe + VMC)

This is your baseline: a process using traditional CNC lathe capabilities for the turning operation, and a separate 3-axis vertical milling center (VMC) for all drilling and milling. This process is the very definition of the multi-setup trap.

Its only remaining valid application? Extremely high-volume, simple parts where you can dedicate two separate, fully automated lines and the (already paid-for) machines can run for weeks on end. For everyone else, this is the process that is creating your scrap bin and killing your lead time.

Option B: The “In-Between” Trap (Lathe with Live Tools & Y-Axis)

This is the most dangerous machine category. Why? Because it looks like a solution. This machine is, at its heart, still just a lathe. Its milling capabilities come from small, driven tools powered by the turret’s servo motor.

Here is the trap we’ve seen engineers fall into time and time again: You buy this machine thinking you’re getting “one-hit” capability. But as soon as you try to perform real milling—like an aggressive face mill, a deep pocket, or a complex 3D contour—you instantly discover its limitations.

The rigidity isn’t there. The torque is insufficient. The Y-axis travel is minimal. The result? For your most complex and profitable parts, you still have to un-chuck the part and move it to the VMC for a secondary operation. You’ve just bought an extremely expensive lathe that failed to solve your single biggest problem.

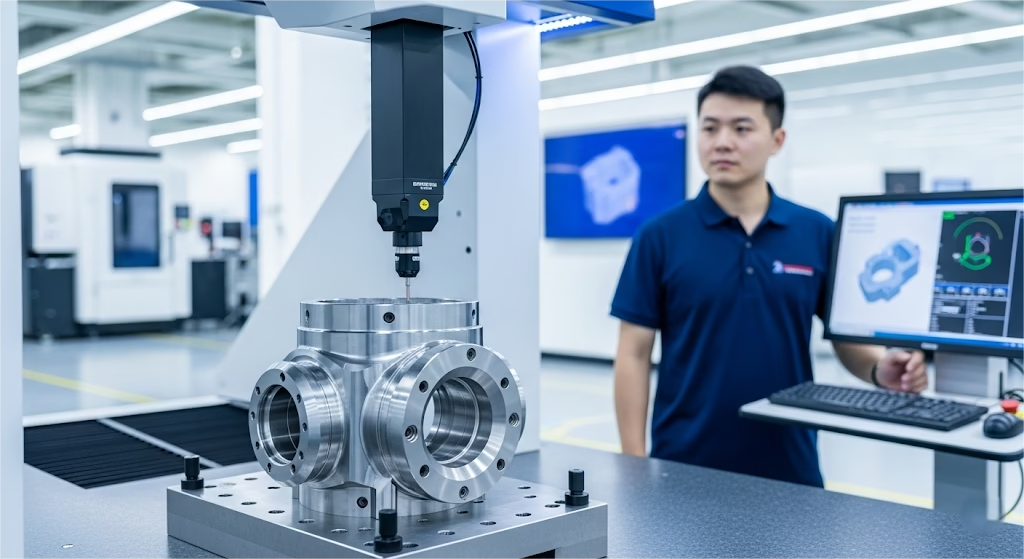

Option C: The True Solution (The Turn-Mill Center)

A true Turn-Mill (or Mill-Turn) center is not a lathe that can mill. It is a completely different machine—a “fused” solution. It is a full 5-axis milling center and a high-performance twin-spindle lathe combined into one chassis.

Its milling power comes from a dedicated, high-torque B-axis milling spindle, often fed by its own 40- or 80-tool ATC. Its “Done-in-One” capability is unlocked by a sub-spindle that can grab the part from the main spindle, transferring it automatically to machine all six faces of the component without ever releasing it.

This is the only machine that physically delivers on the promise of one-hit machining. Yes, the investment is higher, but unlike Option B, it actually solves the problem.

When is Upgrading a Necessity?

This guide isn’t here to just give you a generic comparison. As an engineer, you need a decision model. You need to know the exact “crossover point” where sticking with your traditional process stops being “good enough” and starts being a critical financial liability.

How do you know if you’ve already crossed that line? It comes down to three factors.

Tipping Point 1: When Geometric Tolerance (GD&T) Becomes a Nightmare

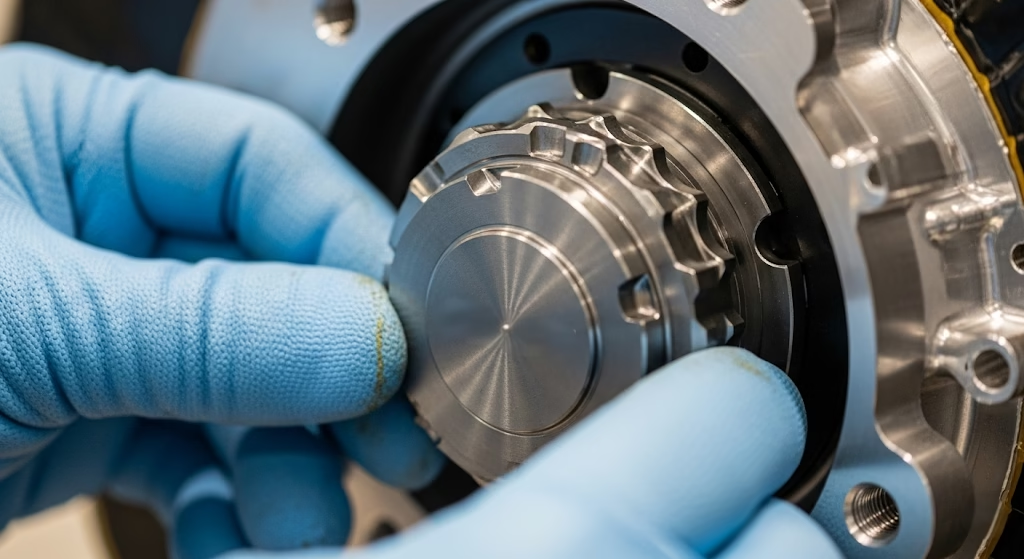

This is the most critical factor. Look at your part drawings. Are you seeing GD&T callouts that require tight positional or coaxial relationships (think < 0.025mm, or 0.001″) between features machined in different setups? Are you chasing concentricity between a turned diameter (Op 1) and a milled hole pattern (Op 2)?

If the answer is yes, you’re already past the tipping point. At this level of precision, you are not just fighting the machine; you are fighting physics. That 5-25 micron error we discussed, which is guaranteed with every re-clamp, makes holding those tolerances a game of chance.

Your scrap rate is a direct, unavoidable consequence of your process. A Turn-Mill, by machining all features from a single chucking, physically eliminates this error source.

Tipping Point 2: When Part Complexity Exceeds Three Operations

Count the setups. If your part needs turning, then milling on the face, drilling on the radius, and maybe an angled hole on the end—it’s a 3+ setup part. Every setup adds labor, fixture design, queue time, and another point of potential error.

The cost of traditional processing doesn’t rise linearly; it rises exponentially with each added setup. A Turn-Mill center is designed to consolidate these operations. That angled hole that requires a custom fixture on your VMC? For a B-axis Turn-Mill, it’s just another toolpath, handled in seconds without ever stopping the machine.

Tipping Point 3: When Your Mix is “High” and Your Volume is “Low-to-Medium”

This is the operational insight that many managers miss. The true power of a Turn-Mill is not just in slashing cycle time (though it does that); its primary ROI comes from eliminating setup time.

If you are running 100,000 of the same simple part, dedicated traditional lines might still compete. But if your shop is like most, you live in a world of High-Mix, Low-to-Medium Volume (HMLV).

You might have 5 different part numbers to run in a single shift. In this environment, your traditional setup (8 hours of setup for 4 hours of run time) is destroying your capacity. A Turn-Mill, with its ability to switch jobs rapidly (often just by calling up a new program and swapping a few tools), turns all that setup downtime back into profitable spindle uptime.

How to Justify the ROI to Management

As an engineer, you’ve analyzed the precision, the process, and the tipping points. You know a Turn-Mill center is the correct technical answer. Now comes the hardest part: proving it to the people who sign the check.

Your manager isn’t looking at the GD&T requirements; they are looking at a massive price tag. Your one and only job is to reframe that price tag. You must stop them from seeing this as a simple “machine cost” and show them that it is a strategic “process investment” with a calculable, rapid payback.

This strategy is about consolidating the entire production flow.

As Dan Janka, President of Mazak Corporation, has stated, the “Done-in-One” philosophy (which Mazak pioneered) “encompasses not just the machine tool, but the total manufacturing process.” By processing a workpiece from raw material to a finished part in a single setup, manufacturers “eliminate multiple setups, reduce work-in-process [WIP] inventory, [and] shorten lead times.”

That is the core of your business case. You are not just buying a machine; you are buying process integration.

When you build your justification report, your numbers must be bigger than the machine’s price. Use these industry benchmarks:

- Manufacturing Throughput: Because “one-hit machining” removes nearly all intermediate queue time (parts sitting in bins waiting for the mill), the total manufacturing lead time—from raw stock to finished part—is often shortened by up to 75%.

- Accuracy & Scrap: By physically eliminating the source of secondary setup errors (re-clamping), scrap rates related to tolerance stacking are slashed. This routinely results in scrap reductions of 50% or more, especially on complex parts.

- WIP & Cash Flow: The “Done-in-One” philosophy typically reduces Work-in-Process inventory by 80% or more. This isn’t just a shop floor benefit; it’s a massive cash flow win that your CFO needs to hear.

Stop Guessing, Start Justifying

This guide is the first step. The next is applying this logic to your parts. Our engineers specialize in analyzing complex parts to provide clear cost-benefit analyses, helping you prove the ROI of advanced machining to your team.

The Four Savings Buckets

Management needs the Payback Period calculation. The machine cost (Initial Investment) is the easy part. Your job is to calculate the “Total Annual Savings (S).” Your calculation must include these four buckets:

- SLabor (Labor Savings): This is the most obvious win. You are eliminating the labor required for all secondary operations: the setup on the mill, the manual part handling, the transfer, and the extra inspection steps. This also frees that highly skilled operator to perform other value-added tasks while the Turn-Mill runs attended.

- SScrap (Scrap Savings): Take that 50% reduction seriously. Calculate your current annual cost of scrap on this part family (including material, time, and labor). Cutting that cost in half is hard cash returned directly to the business.

- SCycleTime (Cycle Time & Capacity Value): By combining operations, you are creating new, profitable capacity out of thin air. You are eliminating the setup time plus the run time of the secondary machines. This new capacity means you can take on more jobs without buying more machines.

- SOverhead (Overhead & WIP Savings): This is the hidden gold. This bucket includes the savings from reducing floor space (one machine replaces two or three), eliminating the cost of designing and building complex fixtures for secondary ops, and the massive financial gain of converting that 80% WIP reduction back into cash.

Facing the Pitfalls We’ve Lived Through

A specification sheet can’t prepare you for the real-world challenges of implementation. This is where most engineers, even the best ones, get blindsided. As someone who has guided dozens of shops through this exact transition, I want to address the fears you (rightfully) have. Your professional credibility is on the line, and avoiding these three proven pitfalls is just as important as your ROI calculation.

Pitfall 1: The Bottleneck Moves from the Shop Floor to Your Office

This is the most common and painful failure we see. You win the budget. You buy a magnificent, $500,000, 9-axis B-axis Turn-Mill center. It lands on your floor. And then… it sits.

Here’s a true story: a client’s machine was delivered, and their most senior programmer—a genius on their 3-axis mills—was completely paralyzed. The company had spent everything on the hardware, assuming their existing CAM could “figure it out” and their team could “learn on the fly.”

For the first three months, that half-million-dollar machine was used as the world’s most expensive 2-axis lathe to run simple shaft work. The trust from management evaporated.

The Solution: You must treat your CAM software (a high-end package like Esprit or Mastercam 5-axis), a professionally built post-processor, and intensive, multi-week programmer training as a mandatory 10-15% line item of the total investment.

Buying the machine without buying the “brain” to run it is a guaranteed failure. You are not eliminating your bottleneck; you are simply moving it from the setup cart to the programmer’s desk. Budget accordingly.

Pitfall 2: The $80,000 Surprise Tooling Bill

This pitfall is just as devastating. An engineer I worked with built a flawless ROI case, but he assumed his existing library of VMC tool holders and lathe turning sticks would just… work. He was wrong.

When the machine was installed, he realized the tight working envelope, sub-spindle, and multi-axis operations required a completely different tooling strategy. He needed modular quick-change systems (like Capto or KM), compact angle heads, high-pressure coolant tooling, and dozens of specialized holders.

His first quote from his tooling supplier to simply get the machine operational was $80,000. His original tooling budget was $15,000. The project was immediately over-budget, delayed, and his credibility was damaged.

Don’t let this be you. Your tooling system is not an accessory; it is a core component of the machine, and it demands its own significant budget line.

Pitfall 3: The “Keep it Busy” Anti-Logic

Once the machine is running, the final trap appears. Management will see their expensive new asset and their first instinct will be, “It must never stop. Put all our parts on it to keep it busy.” This logic is financially toxic.

Your Turn-Mill center has a machine-hour-rate of perhaps $150-$250. Your 20-year-old paid-off lathe is $60/hour. If you run a simple, two-axis turned part on your expensive Turn-Mill, you are actively losing money on every single piece.

Your new job as an engineer is to become a “part segregator.” A Turn-Mill’s ROI comes only from the 20% of your parts that are truly complex: the high-margin, multi-setup, tight-tolerance components. Your traditional, cheaper machines must continue to run the 80% of simple work.

Your Turn-Mill is a surgical scalpel, designed to solve your most complex problems. Do not let management turn it into a sledgehammer.

A Decision Summary and Action Plan

We’ve analyzed the technical traps, the financial justification, and the hidden implementation pitfalls. The decision between a Turn-Mill vs. a Traditional Lathe process is not about which machine is “better”—it’s about matching the right solution to the complexity of your problem.

For your reference, here is the final decision matrix summarizing the three solutions:

| Evaluation Metric | Option A: Traditional Process (Lathe + Mill) | Option B: Live Tool Lathe (The “Trap”) | Option C: True Turn-Mill Center |

|---|---|---|---|

| Primary Capability | Segmented Operations | Turning-dominant, with light milling/drilling. | Fully integrated 5-Axis Milling & Turning. |

| Capital Investment | Low (if machines exist) | Medium | High / Very High |

| Key Limitiation | Catastrophic WIP; Setup bottlenecks; Tolerance stacking. | Lacks rigidity/power for real milling. Fails to solve complex parts. | Requires major investment in CAM software & training. |

| Precision Ceiling | Low (due to multiple setups) | Medium (Consolidates simple features) | Highest. Eliminates all secondary setup error. |

| Best For… | Simple, high-volume parts with loose tolerances. | Simple parts needing basic holes or flats. | Complex parts needing “One-Hit Machining.” |

Stop Guessing, Start Solving

So, what is your next step?

Stop trying to justify this investment by analyzing your entire part library. That approach will fail (as we noted in our “surgical scalpel” insight).

Instead, go to your quality assurance department. Find the “ghost part”—that single component that haunts your shop. It’s the one that always has GD&T arguments, the one that lives in the scrap bin due to tolerance stacking, the one that holds up your most profitable assembly. It’s probably a complex part made of an expensive material, just like that titanium spinal implant case we reviewed.

That one part is your entire business case.

Build your ROI justification around that part alone. Calculate what your company loses every year on that part in scrap, wasted labor, fixture costs, and lost capacity. When you present that data, the decision is no longer about buying a machine; it’s about solving your most expensive problem.

Don’t Buy a Spec Sheet

Ultimately, you should never invest in a spec sheet. You must invest in a process. The only way to eliminate your risk as an engineer is to verify the solution before the purchase order is signed.

This is why our offer isn’t a generic quote. It’s a complete process diagnosis.

Send us the drawing for that one “ghost part.” Our application engineers will provide you with a comprehensive comparative report, detailing the current process cost versus a complete, fully simulated “one-hit machining” solution.

We will deliver the data you need—the final cycle time, the tooling requirements, and the concrete ROI calculation—to build an irrefutable business case for your management team.

Translate This Guide into Action

You have the framework. Now, let our engineering team help you apply it. Send us your most challenging part drawing, and we will build the definitive ROI case to justify your next manufacturing breakthrough.

References & Notes

[1] Expert Viewpoint on Process Integration: The quote from Dan Janka is derived from Mazak Corporation’s foundational “Done-in-One” manufacturing philosophy, which emphasizes process integration (combining all steps from raw material to finished part) as the primary driver for reducing lead times and eliminating handling errors.

[2] The Cost of “Queue Time”: The analysis of “spindle uptime vs. part velocity” references the core bottleneck principles articulated by multiple industry authorities, including Peter Zelinski of *Modern Machine Shop*. The central argument is that idle parts waiting in queue (WIP) represent a greater financial drain than inefficient cutting speeds.

[3] Implementation Budgeting (E-E-A-T): The recommendation to budget 10-15% of the machine cost for software, training, and post-processing is based on direct industry experience (E-E-A-T) from multiple integration projects, where failing to fund this “software ecosystem” is the most common cause of ROI failure for new multi-axis machine investments.