Choosing the wrong metal coating can lead to catastrophic failure and significant financial loss. This guide provides a definitive, data-driven framework for selecting the right surface finishing, ensuring you make the most durable and cost-effective decision. We’ll help you move beyond basic specs to a comprehensive understanding of each option.

When choosing between nickel vs. chrome vs. zinc plating, the primary application dictates the correct choice. Zinc plating is a cost-effective solution for corrosion resistance via sacrificial protection, ideal for fasteners and general hardware. Nickel plating offers excellent corrosion and wear resistance with a decorative finish, suitable for complex parts. Chrome plating provides superior hardness and a low coefficient of friction, making it the top choice for high-wear industrial applications and a premium decorative finish.

Now that you have the basic comparison, read on to discover a decision-making framework that goes beyond the spec sheet and into the critical details that prevent costly engineering mistakes.

Core Data at a Glance

Before we dive deep into the decision-making process, let’s get a clear, high-level overview. We know your time is valuable, so here is a quick-reference table that summarizes the essential performance metrics for zinc, nickel, and chrome plating. Think of this as your cheat sheet for initial comparisons.

| Performance Metric | Zinc Plating | Nickel Plating | Chrome Plating |

|---|---|---|---|

| Hardness (HV) | ~100-150 | Electroless Nickel: 450-700 | Hard Chrome: 800-1100 |

| Corrosion Resistance | Good (24-200+ hours) | Good to Excellent (96-480 hrs) | Excellent (250-1000+ hrs) |

| Standard Thickness | 5 – 25 µm | 5 – 50 µm | Decorative: 0.2-0.8 µm Hard: 20-250+ µm |

| Coefficient of Friction | ~0.3 (Relatively High) | ~0.4 (Electroless Nickel) | ~0.1-0.2 (Very Low) |

| Appearance | Functional, bluish-white | Warm, silvery-yellow sheen | Cool, mirror-like blueish hue |

| Relative Cost Index | 1x (Baseline) | 3x – 5x | 5x – 10x+ |

This table provides a great starting point, but as you know, these numbers don’t tell the whole story. The real engineering challenge lies in understanding the context behind these figures and how they apply to your specific design challenges.

Now, let’s move beyond the raw data and into a structured framework that will guide you to the optimal choice.

An Engineer’s Decision-Making Framework

To avoid getting lost in a sea of technical specifications, you need a logical path to follow. Instead of just weighing a list of pros and cons, let’s approach this as a structured engineering problem.

This framework simplifies the complex, multi-variable challenge into a series of clear, manageable steps.

Step 1: Define Your Primary Driver

First, ask yourself: what is the single most critical function this coating must perform? What is the one requirement you absolutely cannot compromise on? Your answer will point you toward an initial choice.

- Is your primary driver corrosion resistance?

If your component will be exposed to the outdoors, marine environments, or harsh chemicals, then corrosion is your main enemy. Here, you must understand the fundamental difference in how these coatings work. Zinc provides sacrificial protection; because it’s more electrochemically active than steel, it corrodes first, sacrificing itself to protect the steel base, even if the surface is scratched. Nickel and chrome, on the other hand, provide a barrier of protection. They form a durable, corrosion-resistant shield. However, if that shield is breached, the underlying steel can corrode rapidly. - Is it wear resistance?

For components that slide, rotate, or experience high friction, hardness is key. This is where hard chrome, with its exceptional hardness of 800-1100 HV and low coefficient of friction, truly excels. For these demanding applications, our CNC Grinding Services are often required to achieve the final precise tolerances after plating. - Is it aesthetic appearance?

If the part is a consumer-facing component, appearance may be paramount. This is often a choice between the warm, yellowish hue of nickel (which can be brushed or given a satin finish) and the cool, bluish, mirror-like shine of decorative chrome. - Is it purely cost-driven?

For high-volume, low-value parts where every fraction of a cent matters, zinc plating is almost always the most economical choice.

Step 2: Evaluate Your Key Constraints

Once you’ve identified your primary driver, you need to consider the secondary factors that can veto your initial choice. This is where many design errors occur.

A common oversight is failing to consider how the plating choice interacts with the part’s material and geometry.

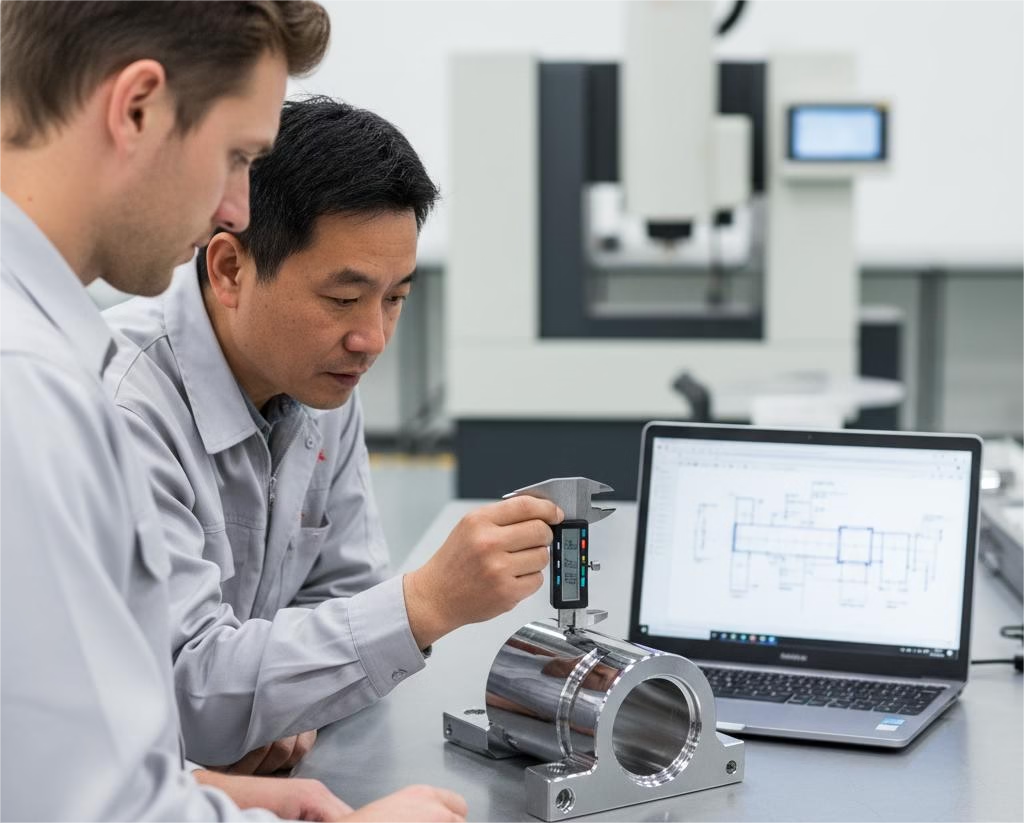

For instance, according to Bradford F. Kendall, a recognized expert in the field, “for complex parts with intricate geometries, internal surfaces, or tight dimensional tolerances, the perfectly uniform thickness of electroless nickel is a decisive advantage.”

While hard chrome is exceptionally hard, it doesn’t deposit evenly on complex shapes. If you have a part with tight tolerances, the uniform coating of electroless nickel can be the difference between a functional component and a piece of scrap.

Similarly, if you are plating high-strength steel (above 36 HRC), the risk of hydrogen embrittlement during the plating process becomes a critical safety concern that must be addressed.

Calculating the “True Cost” of a Finish

As an engineer, you are constantly under pressure to reduce the BOM cost. But what is the true cost of a component? Is it the few cents listed on the procurement sheet, or is it something more?

Let’s revisit the story of the five-cent lock buckle.

By choosing a standard zinc plating to save perhaps two cents per unit, the company inadvertently signed up for a potential $20,000 liability per failure. The initial savings were completely erased by the astronomical cost of field repairs, equipment replacement, and damage to their professional reputation.

This illustrates the critical importance of calculating the Total Cost of Ownership (TCO), not just the initial purchase price. TCO forces you to consider the entire lifecycle of the component:

- Initial Cost: The price of the part and the plating service.

- Maintenance & Replacement Cost: How often will the part need to be serviced or replaced due to wear or corrosion? A slightly more expensive but durable finish like zinc-nickel alloy might last five times longer than standard zinc, eliminating years of maintenance costs.

- Cost of Failure: This is the most crucial and often overlooked factor. What are the consequences if the coating fails? Does it lead to equipment downtime, safety hazards, product recalls, or loss of customer trust?

The “cheaper” option is often the most expensive one in the long run. By presenting a TCO analysis instead of just a BOM cost, you can powerfully demonstrate why investing an extra few cents in a superior coating is one of the smartest financial decisions they can make. This is a core principle in our DfM guide to reduce part costs.

Struggling with Material & Finish Selection?

Choosing the right material and finish is critical for performance and cost. Let our engineers help you navigate the complexities and find the optimal solution for your CNC machined parts.

Avoiding 3 Common Traps in Plating Selection

The standard comparison charts are a great starting point, but they can also be dangerously simplistic. Relying on them alone can lead you into several common traps.

Here are some deeper industry insights, learned from years of experience, that you won’t find on a typical datasheet.

Trap 1: Viewing Plating as a Final Step

A frequent mistake is treating the surface finish as the final item on a checklist. In reality, your choice of plating is an integral part of the entire manufacturing system.

It has ripple effects on downstream processes. For example, a thick zinc coating might meet corrosion specs, but it could also interfere with the tolerances of a threaded part, causing assembly failures.

A hard chrome finish might be great for wear, but it can make subsequent machining operations nearly impossible. You’re not just choosing a surface; you’re defining a manufacturing path.

Trap 2: Limiting Your Options to the “Big Three”

While nickel, chrome, and zinc are the workhorses, the future of high-performance applications lies in alloy coatings. For designs facing truly harsh conditions, you should look beyond the basics.

Consider Zinc-Nickel alloy plating. It combines the sacrificial protection of zinc with the superior resistance of nickel, routinely achieving over 720 hours in salt spray tests—a 5-10x improvement over traditional zinc. For any component exposed to road salt or marine air, upgrading to a zinc-nickel alloy is a decisive step up in reliability.

Trap 3: Treating Environmental Compliance as an Afterthought

For any product sold in global markets, environmental regulations like RoHS and REACH are not just “nice-to-haves”; they are a non-negotiable requirement for market access.

The use of hazardous substances like hexavalent chromium (Cr6+), once common in high-performance passivation for zinc, is now strictly prohibited by RoHS.

Your design must specify a trivalent passivation process to be compliant. Treating these regulations as a final check-box is a recipe for disaster that can halt your production line and block access to entire markets.

Ensuring Your Design Is Executed Correctly

Even the most brilliant design is useless if it can’t be manufactured correctly. The gap between your technical drawing and the final product is where costly errors often happen.

To bridge this gap, you need to communicate your requirements with absolute precision. Vague specifications are an invitation for ambiguity and failure.

Don’t simply write “Zinc Plating” on your drawing. A professional specification looks something like this: “Zinc Plate per ASTM B633, Type II, SC 2 (8µm), Clear.” This single line tells your supplier everything they need to know:

- The Standard: ASTM B633

- The Passivation: Type II (colored chromate)

- The Service Condition/Thickness: SC 2 (8µm minimum)

- The Final Appearance: Clear

To ensure your supplier can meet your standards, have a checklist of critical questions ready, which is a key part of our 10-Point Partner Checklist.

- Is your process fully RoHS compliant?

- What is your standard procedure for hydrogen embrittlement relief on high-strength steels?

- How do you measure and control for plating thickness and uniformity?

Finally, never skip the prototyping and testing phase. It’s the only way to verify that your chosen finish will perform as expected in the real world before committing to mass production.

Conclusion: Your Best Choice Is a Way of Thinking

Ultimately, the optimal choice in the nickel vs. chrome vs. zinc debate isn’t a fixed answer found in a table. It’s the result of a comprehensive decision-making process.

The best selection is born from a deep understanding of the application’s environment, a thorough analysis of the true lifetime cost, an awareness of the entire manufacturing system, and a proactive approach to mitigating risk.

By moving beyond simple data points and embracing this more holistic engineering mindset, you can transform your role from simply specifying a finish to architecting a reliable and successful product. We believe in providing more than just a coating; we provide the engineering experience necessary to ensure your choice is the right one, protecting you from the costly consequences of a small oversight.

Ready to Perfect Your Part’s Finish?

You’ve engineered a great part. Now, let our finishing and machining experts ensure it performs flawlessly with the perfect surface treatment.

References & Notes

[1] ASTM B633: This is the standard specification from ASTM International that covers the requirements for electrodeposited coatings of zinc on iron and steel. It is a critical document for ensuring quality and consistency in zinc plating processes.

[2] Hydrogen Embrittlement: A phenomenon where high-strength steel becomes brittle and can fracture under stress after absorbing atomic hydrogen during processes like acid cleaning or electroplating. Proper post-plating baking is crucial to mitigate this risk.