Tired of receiving CNC machined parts that don’t meet your specs? This guide gives you a proven framework to look past the sales pitches and identify a truly reliable manufacturing partner. We’ll show you how to use the ISO 9001 standard as a tool to guarantee your project’s success.

ISO 9001 certification is crucial for high-precision CNC machining because it mandates a Quality Management System (QMS) that ensures consistency and mitigates risk. This system enforces strict process controls, material traceability, and regular equipment calibration, which directly translates to reliable dimensional accuracy, stable tolerances, and repeatable quality for every part produced.

Now, you’re going to see the exact steps you can take to verify a supplier’s quality system is more than just a piece of paper.

How ISO 9001 Ensures Physical Precision at a Systemic Level

An ISO 9001 certificate is more than just a marketing tool; it’s evidence of a commitment to processes that directly impact the physical attributes of your machined parts.

Let’s break down how the abstract requirements of a quality management system (QMS) translate into tangible, real-world engineering benefits.

| QMS Requirement | Engineering Benefit | Impact on Your Project |

|---|---|---|

| Material Traceability | Performance Certainty | Guaranteed material specs, no risk of counterfeits. |

| Process Control & Calibration | Tolerance Stability | Consistent and repeatable part accuracy. |

| Documented Information (SOPs) | Communication Clarity | Reduced errors from misinterpretation. |

Material Traceability Ensures Performance Certainty

A critical requirement of the ISO 9001 standard is traceability. This means a certified shop must be able to track the journey of the raw materials from the moment they arrive at the facility to the final part shipped to you. For an engineer, this is a crucial safeguard.

We once worked with a medical device startup that, before partnering with us, chose a non-certified, cheaper supplier for a critical prototype. When they requested the material test report (MTR) for the 316L stainless steel used, the supplier could only produce a generic certificate, offering no verifiable proof that the correct material was used. This traceability black hole is a catastrophic risk in a regulated industry.

An ISO 9001 certified system eliminates this risk, ensuring the mechanical properties and chemical composition of your parts are exactly what you specified, every single time.

Calibration and Process Control Deliver Tolerance Stability

The quality management expert Philip B. Crosby famously stated, “Quality is free… What costs money are the unquality things — all the actions that involve not doing jobs right the first time.”

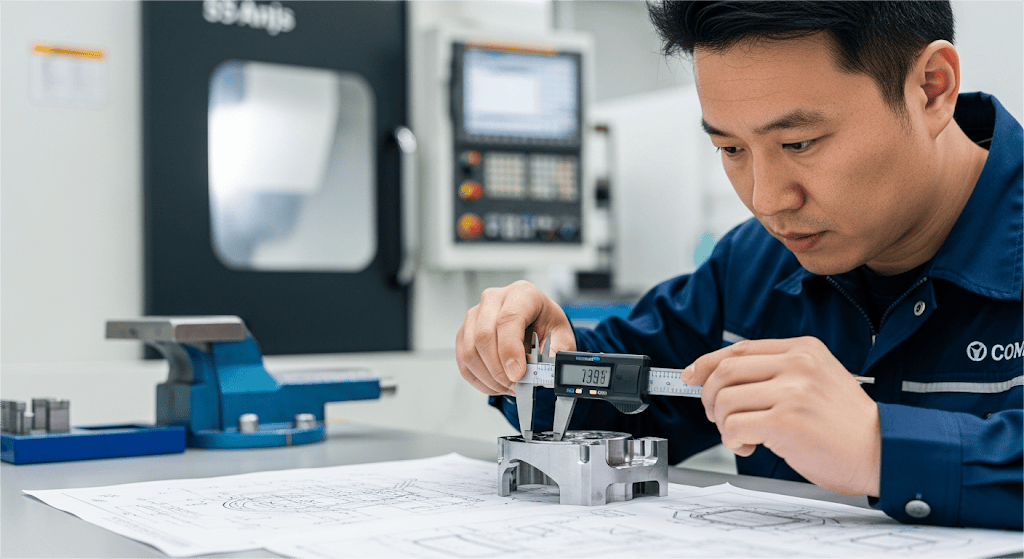

This gets to the heart of process control. The standard mandates the regular calibration of all measuring equipment, from CMMs to calipers. This ensures that when a part is inspected, the data is reliable. Furthermore, it demands control over the production process itself.

This systematic approach is designed to catch deviations early, aligning with the “1-10-100 Rule” of quality costs: it costs $1 to prevent a defect, $10 to correct it in production, and $100 or more to fix it once it has reached the customer. By focusing on process control, an ISO 9001 system ensures that the tolerances on the first part are just as accurate as on the thousandth.

Documented Information Provides Clarity in Communication

Vague instructions lead to inconsistent results. The ISO 9001 framework requires that critical processes are documented in the form of Standard Operating Procedures (SOPs) and work instructions. This means that every step, from machine setup and tool selection with our CNC Milling Services to the final inspection checklist, is clearly defined.

This structured approach replaces ambiguity and assumptions with clear, written directives, ensuring your technical requirements are understood and executed precisely as intended by every member of the supplier’s team.

It’s a system designed to prove the wisdom in W. Edwards Deming’s famous words: “A bad system will beat a good person every time.”

By choosing a supplier with a robust system, you are ensuring the foundation for quality is built into their operations.

Need to Ensure Your Supplier’s Quality?

Our comprehensive quality control process is built on the ISO 9001 framework. See how we guarantee every part meets your exact specifications.

The Engineer’s Due Diligence Checklist for ISO 9001 Suppliers

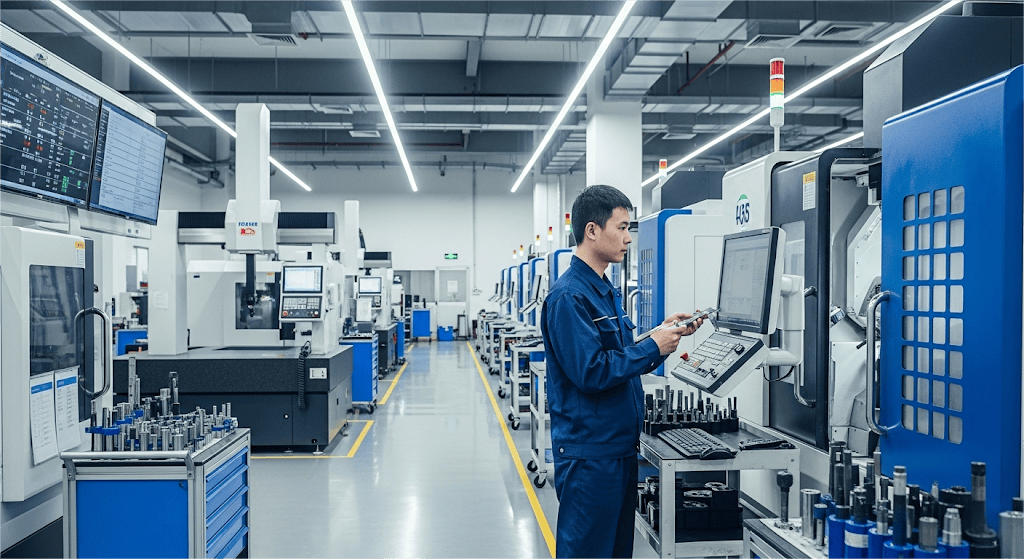

Having an ISO 9001 certificate is a strong starting point, but as you’ve likely experienced, not all certified suppliers operate at the same level, which is why a deep understanding of how to properly vet suppliers is essential.

The real value is in how deeply the quality system is integrated into their culture.

Your task is to determine if the certificate on the wall is a reflection of their daily practices in the workshop. But what happens when the certificate looks good, yet the parts are still bad? That’s a common trap, and it requires vetting quality beyond the certificate.

Here is a practical checklist to help you perform your due diligence:

Identify the “Flavor” of Their Certification

There are two types of certified suppliers: those who get certified to win contracts, and those who get certified because they are genuinely committed to quality. The former treats their QMS as a bureaucratic burden, while the latter uses it as a tool for continuous improvement.

To uncover this, ask a simple but revealing question: “Could you share a recent example of a quality or efficiency improvement that was suggested by a shop-floor employee and implemented through your quality system?” A supplier whose quality system is part of their DNA will have a story to tell. A supplier with a “check-the-box” certification will likely give you a vague, generic response.

Ask Penetrating Questions

Go beyond the basics. The questions below will help you gauge the maturity of their quality system:

- Regarding problem-solving: “Could you provide a sample of a non-conformance report (NCR) you have issued? I’m interested in seeing your standard process for addressing issues.”

- Regarding adaptability: “How do your quality processes and documentation requirements differ for a rapid prototype versus a full-scale production run?” A mature QMS is flexible, offering a “prototyping lane” with streamlined processes, not a one-size-fits-all bureaucratic approach.

- Regarding system reliability: “If the lead machinist for my project were unavailable, how do you ensure the quality of the next production run is identical to the first?” A strong answer will reference documented work instructions, tooling guides, and saved program parameters—not just the skills of another individual.

Request “Process Evidence”

The most reliable evidence of a functioning QMS is the documentation it generates. Don’t hesitate to ask for samples of a First Article Inspection (FAI) report or a Statistical Process Control (SPC) chart for a part with similar features to yours.

These documents are the tangible output of a quality system in action. For procurement managers, knowing how to read a CMM inspection report is a key skill to independently verify this commitment to precision and control.

Leveraging Your Supplier’s QMS to Turn Them into a Technical Partner

The true potential of partnering with a top-tier, ISO 9001 certified supplier goes far beyond simply receiving correct parts on time. When a quality management system is deeply embedded in a company’s culture, it transforms them from a passive order-taker into an active technical partner who can add significant value to your project.

Turn a Contract Review into a Design Optimization Session

A mature QMS requires a thorough contract and design review before a single chip is cut. This is your first and best opportunity to leverage your supplier’s expertise.

We recently worked with a company developing a complex, thin-walled housing for a new drone sensor. The design prioritized minimal weight, but we identified a significant risk during our review process: a critical wall section had a high probability of warping under the stress of machining.

Instead of simply accepting the order and risking failure, our documented Design for Manufacturability (DFM) process kicked in. We provided the client’s engineering team with a brief report, including simulation data, that recommended adding two minuscule, 0.5mm reinforcing ribs.

Because our feedback was based on data, not just opinion, the client confidently approved the change. The result? A 100% first-pass yield. This is the power of a proactive QMS: it identifies and solves problems before they happen.

Use Their Data for Your Continuous Improvement

An ISO 9001 certified supplier is a data-rich environment. They are constantly tracking metrics like First Pass Yield (FPY), scrap rates, and on-time delivery percentages. This data shouldn’t just be for their internal reports; it’s a valuable resource for you.

Don’t hesitate to ask your supplier to share key quality metrics related to your parts. By periodically reviewing this data together, you can identify trends and opportunities for improvement, such as minor design tweaks that could increase manufacturing efficiency or lower costs over the long term, a key part of our High-Precision Manufacturing philosophy.

Benefit from True, System-Level Risk Mitigation

Ultimately, when you partner with a supplier that lives and breathes its quality system, you’re getting more than just parts. You are engaging a partner who is using their entire system to underwrite the success of your project.

They are not just executing your instructions; they are actively managing risk at every step. This deep, systemic approach provides a level of assurance and partnership that a non-certified shop simply cannot offer.

Conclusion: An Engineering Decision that Protects Your Hard Work

Ultimately, choosing a CNC machining partner that has truly integrated the ISO 9001 standard into its DNA is more than a procurement decision; it is a fundamental engineering decision. You are not just buying a certificate; you are investing in a manufacturing system designed for predictability, continuous improvement, and the consistent, faithful execution of your design.

This choice directly protects your most valuable assets: your time, your project’s budget, and your professional reputation. It ensures that your hard work and ingenuity in the design phase are honored with a final product that performs exactly as you intended. By making the quality management system a cornerstone of your selection process, you are choosing a partner who is as invested in the success of your high-precision CNC machining project as you are.

Ready to Partner with a True Precision Expert?

You’ve seen how a systematic approach creates quality. Now, experience it. Let our team of engineers help you turn your complex designs into perfectly executed parts.

References & Notes

[1] The “1-10-100 Rule” of Quality Costs: This is a widely accepted principle in quality management, illustrating that the cost to address a failure increases tenfold as it moves from prevention to correction to post-sale failure.

[2] W. Edwards Deming: A highly influential American engineer, statistician, and management consultant. His work, particularly the concept of the “System of Profound Knowledge,” formed the foundation for modern quality control and the Total Quality Management (TQM) movement.