Tired of your critical projects getting derailed by late CNC parts? This guide breaks down the exact, field-tested system we use to ensure your small-batch production is on time, every single time. Stop leaving your project timelines to chance and start implementing a process you can actually rely on.

Guaranteed on-time delivery for small-batch CNC production relies on a four-pillar system. It starts with systematic pre-production planning and data-driven scheduling. This is followed by transparent execution with a dedicated project manager and proactive communication, all supported by built-in risk management and a culture of continuous improvement.

But knowing the system is one thing.

In the full post below, we’ll break down the exact processes, share the data behind our strategy, and reveal the real-world case study that proves this works.

Why Your Small-Batch Orders Are Always at Risk

If you’ve ever felt like your small-batch order was an afterthought for a large supplier, you’re not imagining it.

The root of delivery uncertainty often lies in a fundamental mismatch between your needs and the operational model of many manufacturers.

The “Small-Batch Paradox” in Large Factories

Here’s the paradox: the very factories that have the most impressive machinery are often the least reliable for small-batch production. Why? Their entire system—from scheduling software and KPI metrics to employee training—is engineered for the efficiency of scale.

Their operational DNA is coded to minimize changeovers and maximize continuous production runs. In this model, your high-mix, low-volume order isn’t a welcome challenge; it’s a disruption.

It’s the “interference” that forces a machine to stop, get retooled, and break the rhythm of a multi-thousand-part run. Consequently, when a larger, more profitable order from a major client comes along, your job is the first to be pushed back.

At a factory optimized for scale, your order isn’t just tolerated; it’s systematically de-prioritized.

The “Hidden Factory” That Consumes Time

The second, less visible culprit is the “hidden factory”—the vast, unmeasured stretches of time where your parts are simply waiting.

The most significant delays don’t happen when the spindle is turning and chips are flying. They occur in the silent gaps between processes.

Think about it:

- Your drawings sit in a programming queue for two days.

- The machined parts wait another day for an inspector to become available.

- A quality issue is found, and the parts are sent back, waiting again for clarification.

These cumulative delays, born from inefficient workflows and a lack of process visibility, are where delivery schedules truly fall apart.

The actual CNC machining might only take a few hours, but the journey through the “hidden factory” can take weeks, consuming your timeline one silent wait at a time.

Our Delivery Philosophy: From “On-Time” to “No Surprises”

We believe you deserve a better promise. In fact, you deserve a better system entirely.

Our entire delivery philosophy is built on a subtle but crucial distinction that changes everything: shifting the goal from simple on-time delivery to a more powerful commitment of “No Surprises Delivery.”

Predictability Is More Valuable Than a Date

Here is a truth we’ve learned from collaborating on thousands of engineering projects: for a project manager or engineer, a one-day delay you are told about on the delivery date is infinitely more damaging than a three-day delay you were warned about a week in advance.

The real pain point isn’t the delay itself; it’s the surprise. It’s the unexpected shock that shatters your project plan and forces you into a reactive, firefighting mode.

You don’t just need your parts on a specific date; you need absolute, unwavering predictability. You need to know that what you were told yesterday will still be true today and tomorrow.

This is why we focus on delivering a predictable outcome, supported by a constant, transparent flow of information.

Our System Is Your Guarantee

This brings us to the core of our philosophy. Our confidence doesn’t come from making bold promises; it comes from having a robust production system designed with a single goal in mind: to make delays the absolute exception, not an accepted part of doing business.

As business management guru Dr. Michael Hammer pointed out, a process isn’t the end goal; its purpose is “to deliver value to a customer.” The value you seek is certainty.

You aren’t choosing us and hoping we keep our word. You are choosing a production system that is engineered from the ground up to eliminate the root causes of delays. The rest of this article is a transparent look into exactly how that system works.

| Common Risk Factor | Root Cause | Our Systemic Solution |

|---|---|---|

| De-prioritization | Large factory’s focus on volume | Specialized small-batch system |

| Process Gaps | The “Hidden Factory” (waiting time) | Transparent execution & PM |

| Material Shortages | Supply chain volatility | Strategic inventory & supplier network |

| Unexpected “Surprises” | Lack of proactive communication | “No Surprises” communication protocol |

Our Four-Pillar Delivery Guarantee System

Our commitment to a “No Surprises” philosophy is supported by a robust, four-pillar system.

This isn’t just a workflow; it’s an operational architecture designed to build predictability into every stage of your order. Let’s break down how each pillar works to protect your project.

Pillar 1: Systematic Pre-Production Planning

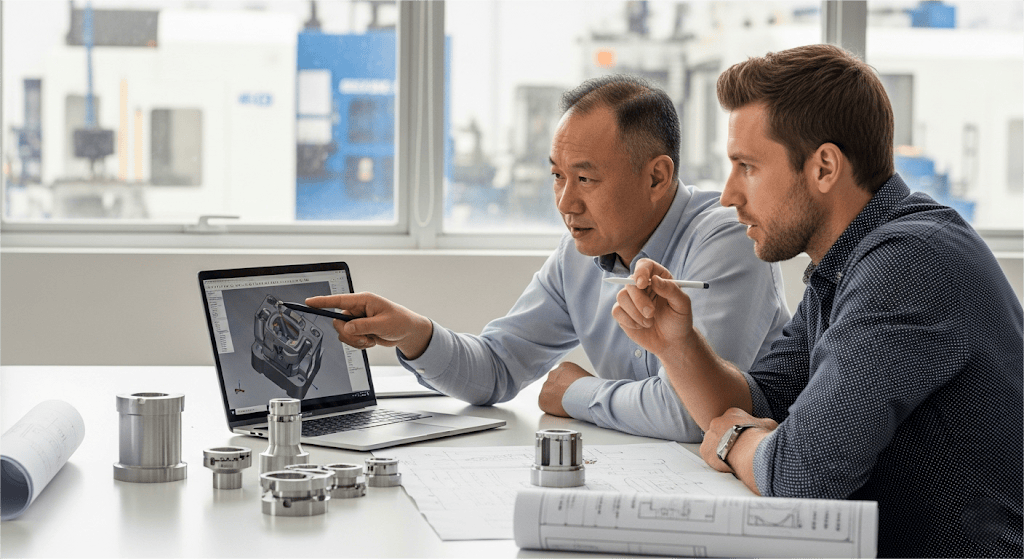

We believe that on-time delivery is decided long before a machine starts cutting metal. It begins with rigorous, intelligent planning that eliminates risks at the source.

- Intelligent Quoting and DFM Analysis: Our quoting process is your first line of defense. When you submit a design, we don’t just return a price. Our system and engineers perform a rapid Design for Manufacturability (DFM) analysis to identify potential challenges—such as deep pockets, thin walls, or complex surfacing—that could cause delays down the line. We address these issues with you upfront, ensuring the design is optimized for a smooth production run.

- Data-Driven Scheduling: The delivery date we provide isn’t an optimistic guess; it’s a scientific calculation. Our Advanced Planning and Scheduling (APS) system processes dozens of real-time variables, including current machine workloads, tool availability, operator schedules, and raw material lead times. This data-driven approach produces a realistic, achievable delivery date, turning uncertainty into a predictable forecast.

Pillar 2: Transparent Execution

The moment you place an order, the dreaded “black hole” of communication begins at many shops.

Our second pillar is designed to eliminate it entirely by giving you a clear window into your project’s progress.

- Your Dedicated Project Manager: You will never be bounced between departments. From start to finish, you will have a single point of contact: a dedicated Project Manager who serves as your internal advocate. They own your project, coordinate all resources, and are fully accountable for its success.

- Proactive Communication Protocol: You shouldn’t have to ask for an update. We operate on a proactive, milestone-based communication schedule. We will reach out to you with clear status updates at key stages: order confirmation, material arrival, production start, first article inspection, and finally, shipment with a tracking number. You will always know exactly where your project stands.

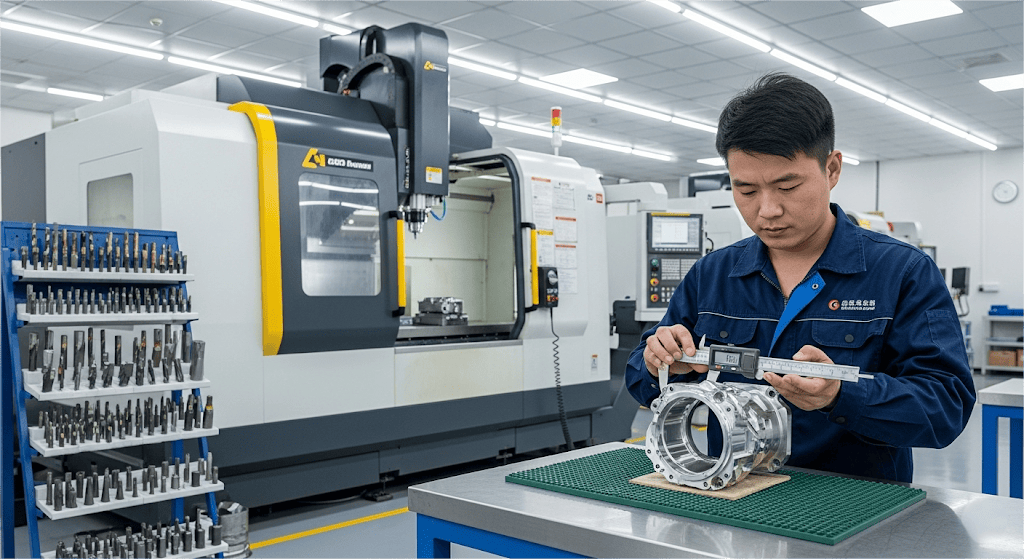

Need Reliable 5-Axis Machining?

Our advanced 5-axis capabilities are a core part of our delivery guarantee, enabling us to machine complex parts efficiently and with ultimate precision. See how our technology can support your most demanding projects.

Pillar 3: Built-in Risk Management

A perfect plan is not enough; a resilient plan must account for real-world variables.

Our third pillar is about having a robust Plan B that is already integrated into our daily operations.

- Strategic Material & Supply Chain Control: Industry data shows that up to 50% of production delays are caused by material shortages. We mitigate this primary risk by maintaining a strategic inventory of common materials (like Aluminum 6061, Stainless Steel 304, and PEEK) and cultivating a network of vetted, reliable backup suppliers.

- Equipment Redundancy & Cross-Trained Personnel: A single point of failure can bring a project to a halt. We prevent this by having multiple, similar high-precision CNC machines. If one machine is down for maintenance, your job seamlessly moves to another. Likewise, our key operators are cross-trained on multiple pieces of equipment, ensuring that a personnel shortage never becomes your project’s bottleneck.

As Dr. Eliyahu M. Goldratt famously stated, “An hour lost at a bottleneck is an hour lost for the entire system.”

We design our system to minimize those bottlenecks.

Pillar 4: A Culture of Continuous Improvement

Finally, our system is designed to learn and evolve. We are relentless in our pursuit of operational excellence, using data to refine our processes and ensure that every delivery is better than the last.

- Rigorous Data Tracking: We obsessively track our performance using key metrics like On-Time Delivery (OTD) and the more demanding On-Time In-Full (OTIF). For any delivery that deviates from the plan, we conduct a thorough Root Cause Analysis (RCA) to understand why and implement corrective actions.

- Customer Feedback Loop: Your experience is a critical source of data. We have a structured process for collecting and analyzing your feedback, using your insights to drive meaningful improvements to our communication, quality, and delivery systems.

Example: A Rescue Mission for CardioTech’s FDA Submission

Theory and systems are one thing, but how does this work in a real-world, high-stakes crisis?

Let us share the story of a medical device startup we’ll call “CardioTech.”

The Crisis

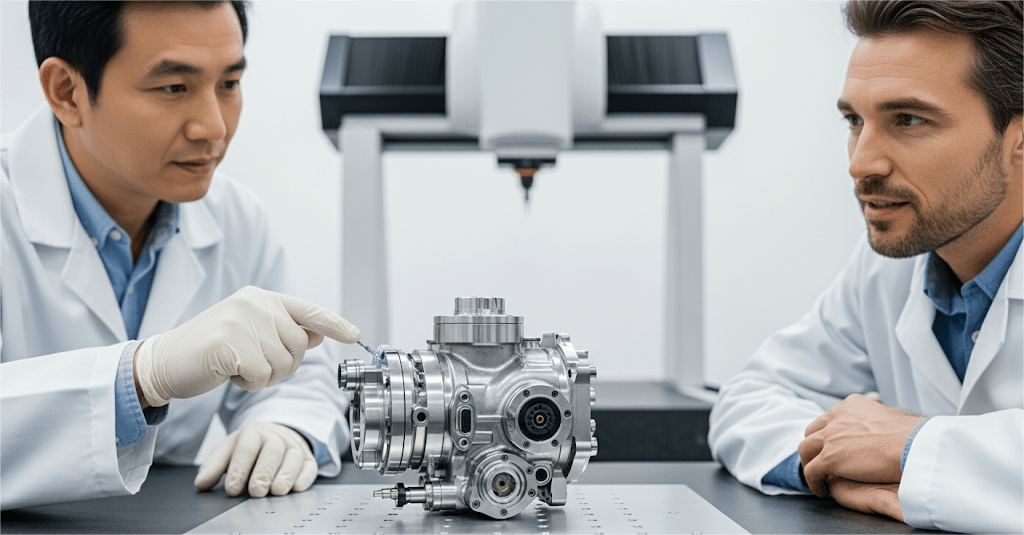

CardioTech was on the verge of a breakthrough. They had developed a revolutionary cardiac device and were preparing for the critical clinical trials needed for FDA approval.

Their next round of funding and the entire future of their company hinged on these trials starting on schedule. They had ordered a set of complex, high-tolerance PEEK components from a very large, well-known manufacturing firm.

Just one week before the scheduled delivery, they received a devastating email. The supplier was pushing the delivery back by three weeks.

The reason? A massive order from an aerospace giant had come in, and CardioTech’s “small-batch” job was bumped. The project was in jeopardy, and the CTO was facing a crisis born from being treated as a low-priority customer.

Our Intervention

When CardioTech’s CTO called us, he wasn’t just looking for a new quote; he was looking for a lifeline. Here’s how our four-pillar system immediately kicked into action:

- Instant Expert Consultation: Instead of simply quoting, we immediately organized a 30-minute “technical rescue” call between their CTO and our lead process engineer. We reviewed the CAD files together, screen-to-screen, and identified two minor design tweaks that would maintain integrity while significantly improving machinability. This wasn’t a sales call; it was a collaborative, problem-solving session.

- Transparent Scheduling: We didn’t make a vague promise. We took a screenshot of our live APS scheduling system and showed him exactly which 5-axis machine his parts would run on, when they would run, and how much time was allocated for quality inspection. We replaced his uncertainty with verifiable data.

- Proactive Communication: To eliminate any further anxiety, we created a dedicated Slack channel for the project. We committed to posting an update every morning at 9 AM and every afternoon at 4 PM, even if it was just to say, “Everything is running on schedule.”

The Outcome and the Lesson

We delivered the fully qualified components two days ahead of the emergency schedule. CardioTech’s clinical trials proceeded without a hitch.

The experience taught us all a valuable lesson: for critical, small-batch projects, the “fit” of your supplier is far more important than their size.

You don’t just need a vendor with the right machines; you need a partner whose entire business model is built to prioritize and protect your project.

What This Guarantee System Means for Your Next Project

So, what does this systematic approach to on-time delivery actually mean for you and your team?

It means transforming the entire dynamic of your partnership with a manufacturing supplier.

For the Engineer:

It means you finally get a true manufacturing partner, not just a job shop. You can hand off your designs with the confidence that they will be executed with precision and returned on schedule, allowing you to focus on what you do best: designing and innovating.

Our system is designed to accelerate your R&D cycles by providing reliable, fast-turnaround prototypes and small-batch parts. No more chasing down orders or explaining delays; just a seamless transition from CAD model to physical component, empowering you to test, iterate, and perfect your creations faster.

For the Project Manager:

It means you can confidently remove “supplier delay” from your project risk list. Our entire system is built to provide the one thing your role demands above all else: predictability.

You get a reliable partner who understands that your timeline is not just a suggestion, but the critical path to success. By providing transparent, proactive communication and a resilient production process, we help you safeguard your project schedule, maintain your credibility, and deliver on the promises you’ve made to your team, your leadership, and your customers.

Ready to Experience a “No Surprises” Delivery Model?

If you’re tired of the risks and uncertainty that come with small-batch CNC production, it’s time to try a different approach.

It’s time to partner with a team whose system is built from the ground up to provide the predictability your critical projects demand.

Let us show you the difference a true delivery guarantee system can make.

Upload your CAD file today. You won’t just get back a quote. You’ll receive a complimentary preliminary DFM analysis and a reliable delivery timeline calculated by our precision scheduling engine.

Let’s work together to inject certainty into your supply chain from the very first step and ensure the on-time delivery for small-batch CNC production that your project deserves.

Ready to Build a Reliable Supply Chain?

You’ve seen our system for guaranteeing delivery. Now, let our experts provide the precision parts and predictable timelines your projects deserve.

References & Notes

[1] Theory of Constraints: The quote “An hour lost at a bottleneck is an hour lost for the entire system” is a central tenet of the Theory of Constraints, detailed in Dr. Eliyahu M. Goldratt’s book, “The Goal.”

[2] Cost of Delay: The analysis of profit loss due to launch delays is a well-established principle in product development strategy, with foundational studies conducted by firms like McKinsey & Company.

[3] OTIF Metric: On-Time In-Full (OTIF) provides a more holistic view of delivery performance than simply tracking on-time rates, as it penalizes for incomplete or incorrect orders, which can equally disrupt a production line.