Frustrated by CNC quotes that promise savings but deliver budget-breaking problems? This guide provides a proven Total Cost of Ownership (TCO) framework to move beyond the price tag, helping you eliminate hidden fees for predictable, profitable projects.

The true cost of a CNC part includes hidden expenses like rework from high scrap rates that increase total spend, engineering overhead from managing poor suppliers, and costly project delays that jeopardize launch schedules.

But identifying these hidden costs is only half the battle. Simply knowing they exist doesn’t provide a systematic way to compare two vastly different quotes.

The real challenge lies in quantifying these risks before you commit. What follows is not just a list of tips, but the simple decision-making framework that top engineering leads use to transform ambiguous risk into a hard number, ensuring they can defend their choice with data, not just gut feeling.

The Iceberg Below the Surface: Quantifying the Hidden Costs

The fundamental flaw in a price-tag-only analysis is that it treats manufacturing as a simple transaction. It’s not. It’s a process, and a flawed process creates waste that you ultimately pay for.

This is why a quote may include NRE (Non-Recurring Engineering) Costs, which represent the upfront investment in building that high-quality process.

Experts call this the Cost of Poor Quality (COPQ), and according to the American Society for Quality (ASQ), it can cost companies between 15% to 25% of their annual sales. That’s a staggering figure, and it’s where the true cost of that “cheap” part is hiding.

To find it, you need to think in terms of Total Cost of Ownership (TCO). This isn’t just an accounting term; it’s a decision-making framework for calculating all the costs associated with a part, including a deep dive into material choice’s impact on machining cost.

Let’s break down the three biggest hidden costs that never appear on a quote.

1. Rework & Scrap Costs (C_rework)

This is the most straightforward hidden cost. But beyond these process-related risks, it’s crucial to understand the most significant factor on any quote: how production volume affects price.

When a batch of parts arrives out of tolerance, with poor surface finishes, or made from uncertified material, what happens?

- Direct Loss: The defective parts are scrapped. You paid for them, and now they are worthless.

- Internal Labor: Your team spends time on receiving, inspecting, and identifying the non-conforming parts.

- Shipping & Logistics: You incur costs sending parts back or waiting for a new shipment.

A low-cost supplier might not have robust quality control processes, meaning a higher scrap rate is a statistical probability, a critical factor when evaluating high-risk operations as detailed in this thread milling vs. tapping guide. Even a 10% scrap rate on a $42,500 order instantly adds $4,250 to your “true cost.”

2. Engineering & Management Overhead (C_overhead)

This is the most underestimated—and often the largest—hidden cost. Your time, and your engineers’ time, is your company’s most valuable resource. An unreliable supplier drains this resource at an alarming rate, which is why evaluating their project management process is so critical.

Think about the hours spent on:

- Endless email chains trying to clarify technical details, a problem often solved by creating a comprehensive guide to the RFQ for high-precision CNC machining services from the start.

- Phone calls at odd hours to accommodate different time zones—a major factor in any local vs. overseas TCO framework.

- Debating whether a cosmetic defect is “acceptable.”

- Managing the fallout of a delayed shipment.

A senior engineer’s loaded hourly rate can easily be over $100. If you spend just 10 extra hours managing a problematic supplier over the course of a project, that’s $1,000 of pure overhead that has evaporated from your budget. That “saving” from the cheaper quote vanishes quickly.

3. Delay & Opportunity Costs (C_delay)

What is the cost of a one-week delay to your project?

This cost is harder to quantify but is often the most damaging, which is why understanding how a supplier guarantees on-time delivery is so critical. If a critical part is late, it can trigger a cascade of expensive consequences:

- Production Line Stoppage: Your assembly line sits idle, wasting labor and capacity.

- Delayed Product Launch: You miss your launch window, giving competitors an advantage and delaying revenue.

- Contract Penalties: You may face penalties for being late on a customer commitment.

As the legendary quality guru Dr. W. Edwards Deming famously stated:

“A rule that says ‘give the business to the lowest bidder’ will result in poor quality and high cost.”

He understood that the initial price is meaningless without a guarantee of quality and reliability, because the downstream costs of failure always outweigh the upfront savings.

Quick-View: Hidden Cost Comparison

| Hidden Cost Factor | Low-Price Supplier Risk | Cost Impact Example |

|---|---|---|

| Rework & Scrap (C_rework) | Higher defect probability | +$4,250 (on a 10% scrap rate) |

| Management Overhead (C_overhead) | Increased communication & problem-solving time | +$1,000 (for 10 extra eng. hours) |

| Delay Costs (C_delay) | Launch delays, production line stoppage | +$10,000s (in opportunity cost) |

How to Vet Suppliers Like an Expert: The Beyond-the-Price Checklist

To confidently assess the true value of a quote, you need to ask better questions. Moving beyond price requires you to interview your potential suppliers to understand their processes, not just their promises.

Here is a practical checklist designed to help you distinguish a true manufacturing partner from a simple order-taker.

1. Probe Their Quality Process

Don’t just ask if they have a certification; ask how they implement it. This reveals their real-world commitment to quality and their rigorous quality control process.

- Instead of asking: “Do you have ISO 9001 certification?”

- Ask this: “That’s great you’re certified. Could you walk me through your specific process for handling a non-conforming part? From the moment a problem is found to the corrective action report (CAR), how is the customer involved and kept informed?”

- Follow-up question: “What are your standard inspection procedures? Do you perform first-article inspection (FAI), and can we get a copy of the report with our first shipment?”

2. Verify Their Technical Experience

A supplier’s website might list dozens of capabilities. You need to know if they have specific, relevant experience with a project like yours.

- Instead of asking: “Can you machine Titanium?”

- Ask this: “Our part is made from Ti-6Al-4V and requires tight tolerances. Could you share an example of a recent project you’ve completed with a similar material and complexity? What challenges did you encounter, and how did you resolve them?”

- Follow-up question: “What are your thoughts on our part’s design for manufacturability (DFM)? Do you see any features that could be modified to improve quality or reduce machining time without impacting function?”

3. Understand Their Communication & Project Management

Smooth production is built on clear and timely communication. A cheap quote is worthless if you can’t get a straight answer when problems arise.

- Instead of asking: “How long will the quote take?”

- Ask this: “Once the project kicks off, who will be our single point of technical contact? What is your standard communication frequency, and what is your process for handling an urgent design change mid-production?”

- Follow-up question: “How do you track and communicate project status? Do you use a project management portal, or will we receive email updates?”

A high-quality supplier will welcome these questions and provide confident, detailed answers. A supplier who is merely competing on price may be evasive or unprepared. Their response will tell you everything you need to know.

Case Study: How a $12,500 “Saving” Nearly Derailed a Product Launch

Theory and checklists are useful, but a real-world example demonstrates the stakes better than anything. Let’s look at the story of “Innovate Robotics,” a promising startup that learned the true cost of a CNC part the hard way.

The Setup

Innovate Robotics was preparing to launch its new collaborative robot. The centerpiece was a sleek controller with a precision-machined 6061-T6 aluminum housing. It was a critical cosmetic and structural component.

They received two quotes for a run of 500 housings:

- Our Quote (The Value Partner): $110 per unit, for a total of $55,000. We included a complimentary DFM report suggesting minor tweaks to two internal corner radii to increase strength and reduce machine time.

- Supplier B (The Low-Cost Option): $85 per unit, for a total of $42,500. The quote was fast and impressively cheap.

Facing pressure from investors to manage their burn rate, the choice seemed obvious. They went with Supplier B, booking a satisfying $12,500 in upfront savings.

The Unraveling

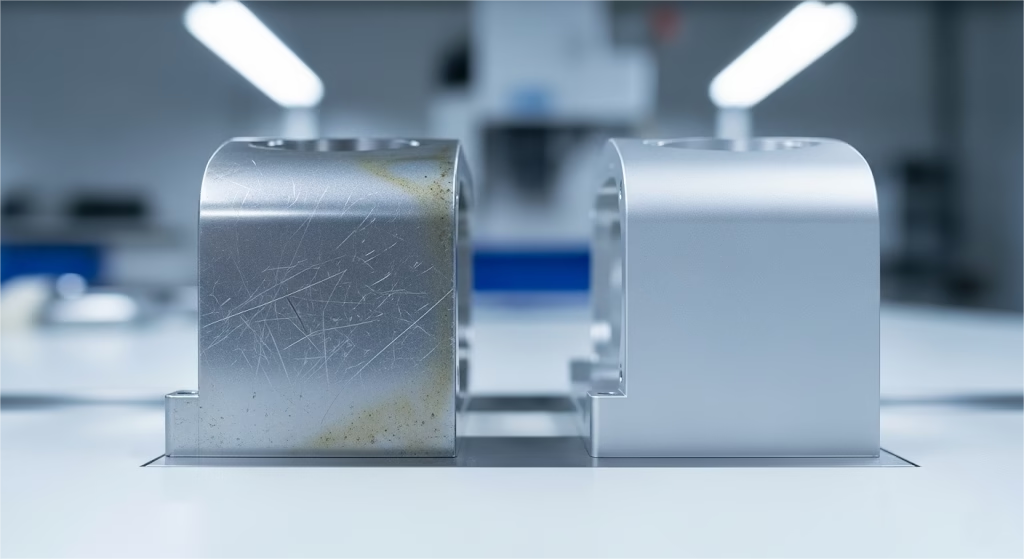

The first batch of 100 housings arrived, and the “savings” began to evaporate.

- Tolerance Stacking Failure: Around 30% of the housings had incorrectly toleranced anodizing. The supplier hadn’t accounted for the thickness of the anodized layer, making the internal mounting holes for the PCB too tight. The boards simply wouldn’t fit.

- Cosmetic Defects: Over 20% of the parts had visible surface scratches and inconsistent color from the anodizing process—unacceptable for a primary cosmetic component.

- The Communication Black Hole: When Innovate Robotics raised these issues, the supplier was slow to respond and deflected blame, claiming the defects were “within industry standards.” Communication across time zones was frustratingly inefficient.

The True Cost of the “Deal”

The team scrambled to assess the damage. The cheap quote was now generating very real, and very high, costs.

- Direct Material Loss: 50 unusable parts × $85/unit = $4,250

- Wasted Engineering Time: Their lead mechanical engineer spent nearly 40 hours—a full work week—sorting parts, documenting defects, arguing with the supplier, and trying to find a fix. At a conservative blended rate of $120/hour, that’s another $4,800 in pure overhead.

The total tangible cost of the problems had already reached $9,050, wiping out 72% of their initial “savings.”

But the biggest cost was the one they couldn’t easily measure: time. With their product launch just a month away, they faced the terrifying prospect of not having enough working controllers. The entire company’s market momentum was at risk.

This is the very definition of a false economy. The decision to save a few dollars upfront created a far more expensive problem downstream. It proves that choosing a manufacturing supplier isn’t a simple purchase; it’s an investment in certainty.

From Supplier to Partner: Building Your Competitive Advantage

The most experienced engineering leaders don’t think in terms of “finding a good supplier.” They think in terms of “building a strategic supplier portfolio.”

They understand that the goal isn’t just to buy a part; it’s about building a resilient supply chain through strategic partnerships. This is your ultimate competitive advantage.

This shift in mindset from a transactional relationship to a partnership model is crucial. A supplier simply executes a purchase order. A partner actively works to make your product better and your process more efficient.

As Taiichi Ohno, the father of the Toyota Production System, wisely noted:

“Costs do not exist to be calculated. Costs exist to be reduced.”

A low quote is a static calculation. A true partner helps you actively reduce costs by eliminating waste in all its forms—defects, delays, and wasted engineering time.

Develop a Tiered Supplier Portfolio

The most sophisticated approach isn’t to find one perfect supplier for everything. It’s to build a small, trusted portfolio tiered to your needs:

- Tier 1: The Strategic Partners. These are your go-to experts for the most critical, tight-tolerance components where the cost of failure is catastrophic. Their quotes may be higher, but they function as an extension of your engineering team. They provide proactive DFM feedback and can handle the most complex challenges.

- Tier 2: The Reliable Workhorses. These are trusted suppliers for the majority of your standard parts. They have proven quality, reliable communication, and competitive pricing. You don’t need them to co-design your product, but you trust them to deliver consistently.

- Tier 3: The Speed & Prototype Players. For non-critical internal brackets, early-stage prototypes, or fit-checks, speed and low cost are the primary drivers. You use this tier for jobs where you can tolerate more management overhead and a higher risk of minor imperfections.

A mature sourcing strategy isn’t about finding the lowest price for every part. It’s about having the wisdom to match the right part to the right tier of supplier, a decision detailed in this 3-axis vs. 5-axis machining analysis. This article’s entire purpose is to give you the tools to make that judgment call correctly.

The Litmus Test: How They Handle DFM

The single best indicator of a supplier’s potential as a partner is how they approach Design for Manufacturability (DFM).

- A low-cost supplier sees your CAD file as a final instruction. They will machine it exactly as requested, even if they spot features that will increase cost, risk failure, or compromise quality.

- A true partner sees your CAD file as the start of a conversation. They will proactively come back to you with suggestions like:

- “We noticed this internal pocket has sharp corners. By changing them to a 0.5mm radius, we can use a standard end mill instead of slow EDM, which will reduce the part cost by 15%.”

- “This wall thickness is quite thin. Have you considered adding a small rib here to improve rigidity during machining and prevent warping?”

Optimizing for Complex Features?

Our CNC Milling Services are built on proactive DFM feedback to solve challenges like internal pockets and thin walls.

This proactive feedback is where value is created. It is the clearest possible sign that the supplier is invested in your success, not just in winning the order.

Your Decision Defines Your Value

Choosing a CNC machining supplier is never just a line item on a budget. It’s a critical decision that reflects your priorities as an engineering leader.

Your value to your organization comes not just from managing costs, but from proactively managing risk and ensuring project success. By shifting your focus from the initial quote to the total cost, you move from being a price-taker to being a value-driver.

The frameworks and stories in this guide are designed to empower you to make that shift. You now have the tools to quantify hidden costs, the questions to vet suppliers like an expert, and the real-world evidence to justify your decisions to your team.

Beyond CNC: A Universal Principle for Manufacturing

Now that you have a robust framework for evaluating CNC machining, you might be wondering: how does this apply to other manufacturing processes like injection molding or sheet metal fabrication?

The answer is: the underlying principles are universal. While the specific technical questions will change, the core methodology of looking beyond the price tag remains the same. The costs of poor quality—rework, overhead, and delays—are present in every manufacturing discipline. By mastering this TCO-focused mindset for CNC, you’ve developed a strategic competency that will make you a more effective leader across your entire supply chain.

Start with a Risk-Free Quote

Are you ready to experience a quoting process that prioritizes value and certainty?

Upload your CAD file today. Our engineering team will do more than just return a price. We will provide you with a comprehensive quote that includes a complimentary DFM analysis, highlighting opportunities where you can genuinely reduce costs without sacrificing quality or function. This is your first step toward understanding the true cost of CNC parts and building a partnership that pays dividends long after the invoice is settled.