This is the definitive guide to Design for Manufacturability (DFM) for small, complex turned parts. We’ll show you exactly how to optimize your designs to slash manufacturing costs and accelerate your time to market. Stop fighting with your machine shop and start designing parts that are both brilliant and buildable.

To optimize the design of small, complex turned parts, focus on three key areas:

- Material Selection: Choose materials based on a balance of performance, cost, and machinability, not just performance alone.

- Geometric Design: Design features like internal corners and wall thickness for “one-hit” CNC Swiss turning to eliminate costly secondary operations.

- Smart Tolerancing: Apply tight tolerances only to critical functional surfaces to avoid exponential cost increases.

Ready to see how a simple change to an internal corner can cut costs by 200%? We break down the exact DFM strategies for small, complex turned parts, including actionable data and case studies on tight tolerance turning.

Strategic Mindset: The Multiplier Effect of Cost

Before you draw the first circle or extrude the first feature, let’s establish a new way of thinking about cost. Experienced engineers understand that the total cost of a component isn’t a simple sum of its features.

Our team, specializing in complex turned parts, knows that the cost is instead a multiplier effect, where each design choice amplifies the cost of the others. Instead, it’s a multiplier effect, where each design choice amplifies the cost of the others.

Imagine it with this simple formula:

Total Cost ≈ (Base Machining Time) x (Material Factor) x (Tolerance Factor) x (Complexity Factor)

A seemingly small decision, like choosing a slightly more exotic material, doesn’t just add a fixed amount to the bill. It multiplies the cost across every other factor. That harder material increases machining time, makes holding tight tolerances more difficult, and can limit the complexity of features you can create efficiently.

This is why a myopic focus on “piece price” can be misleading, especially in today’s global landscape. A part that costs $0.50 less from an overseas supplier might seem like a win, but what is the total cost of ownership?

If that part is delayed by three months due to shipping, or if a quality issue requires hours of your time in conference calls across time zones, the initial savings are quickly erased.

For American companies, particularly in the medical or aerospace sectors, supply chain resilience and clear communication are now calculated as real, quantifiable value. Adopting this strategic mindset is the first step toward designing parts that are not just functionally sound, but also commercially viable.

Pillar 1: The Strategic Triangle of Material Selection

Choosing the right material is one of the earliest and most impactful decisions you’ll make. The best way to approach this is by envisioning a “strategic triangle” with three competing points: Performance, Cost, and Machinability. You can rarely maximize all three; a gain in one area often requires a trade-off in another.

For instance, 316L Stainless Steel offers exceptional corrosion resistance (high performance), but it’s more expensive and harder to machine than its cousin, 303 Stainless Steel. This is where understanding the true need becomes critical.

We recently worked with a client designing an internal testing fixture. They had defaulted to 316L, their company’s standard for medical-grade products. We saw this and asked a simple question: “What is the operating environment for this specific part?”

It turned out the fixture would only be used in a dry, room-temperature lab. We suggested switching to 303 Stainless Steel. The material was more than adequate for the application, and its superior machinability cut the part cost by nearly 40%.

This proactive “downgrade” is a perfect example of experience in action. It’s about looking past the “what” on the drawing to understand the “why” behind it.

Here’s a quick reference to guide your thinking:

| Material | Relative Cost | Machinability Rating* | Key Characteristics |

|---|---|---|---|

| Brass 360 | 1.0x | 90% | Excellent machinability, conductive |

| Stainless Steel 303 | 1.8x | 78% | Good corrosion resistance, easy to machine |

| Stainless Steel 316L | 2.2x | 42% | Superior corrosion resistance, biocompatible |

| Titanium (Ti-6Al-4V) | 8.0x | 22% | High strength-to-weight, biocompatible |

| PEEK | 15.0x+ | 55% | Biocompatible, high-temp resistance |

*Based on a 1212 Steel rating of 100%.

By using this framework, you move from simply picking a material to making a strategic choice that balances every project constraint.

Pillar 2: Designing Geometry for “One-Hit” Machining

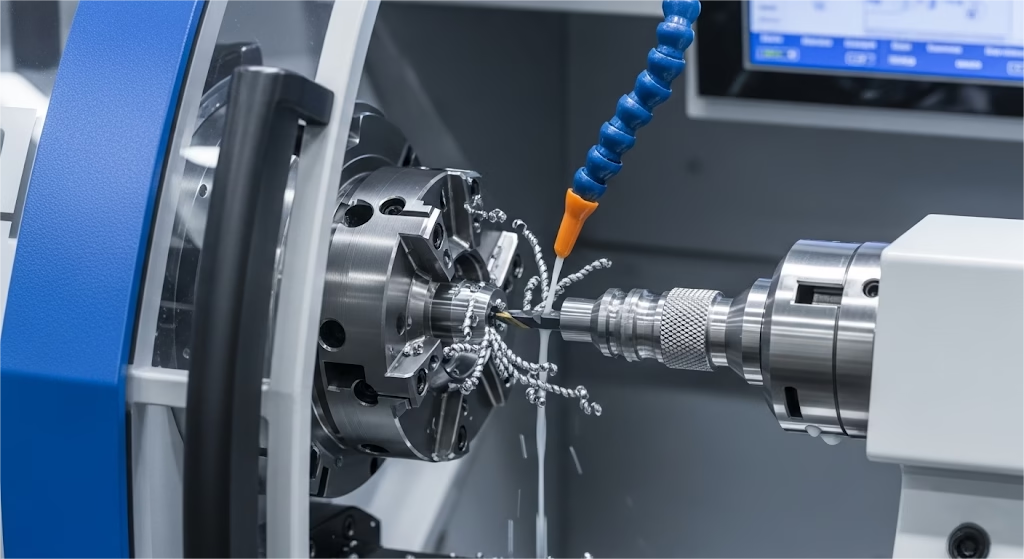

This is where your design choices have a direct, physical impact on the manufacturing process. The goal is to design features that can be completed in a single setup on a CNC Swiss-type lathe, what we call “one-hit” machining.

Avoiding secondary operations—like moving a part to another machine for milling or deburring—is the single most effective way to reduce both cost and lead time.

Internal Corners and Features

Sharp internal corners are a common and costly design feature. A standard cutting tool has a radius, making a perfect 90-degree internal corner impossible to machine in a single pass.

- Costly Design: Specifying a sharp internal corner (a radius of 0). This requires a secondary process like Electrical Discharge Machining (EDM), which can increase the part’s cost by 200% or more.

- Efficient Design: Designing a corner with a radius of at least 0.25mm (0.010″). This allows a standard tool to create the feature quickly and cleanly during the main turning cycle.

Don’t let your assumptions about what’s possible limit your design, however. We once had a client designing a connector with a complex internal undercut they believed was impossible to machine. They were about to split it into a two-piece, assembled part.

Our solution was a custom-ground form tool that created the “impossible” feature in a single, 0.5-second pass on the lathe. Before you compromise your design, talk to your manufacturing partner.

Wall Thickness and Deep Holes

When working with small diameter turned parts, maintaining part rigidity is key.

- Wall Thickness: For metals like steel and titanium, try to keep wall thickness above 0.5mm (0.020″). Thinner walls can lead to vibration, chatter, and deformation under cutting pressure, compromising your tolerances.

- Deep Holes: A standard rule of thumb for drilling is to keep the hole’s depth-to-diameter ratio below 4:1. While specialized processes can go deeper, this is a safe starting point. When a part’s length-to-diameter ratio exceeds 7:1, a Swiss-type lathe becomes the most effective and economical option, as its guide bushing provides the necessary support to maintain stability.

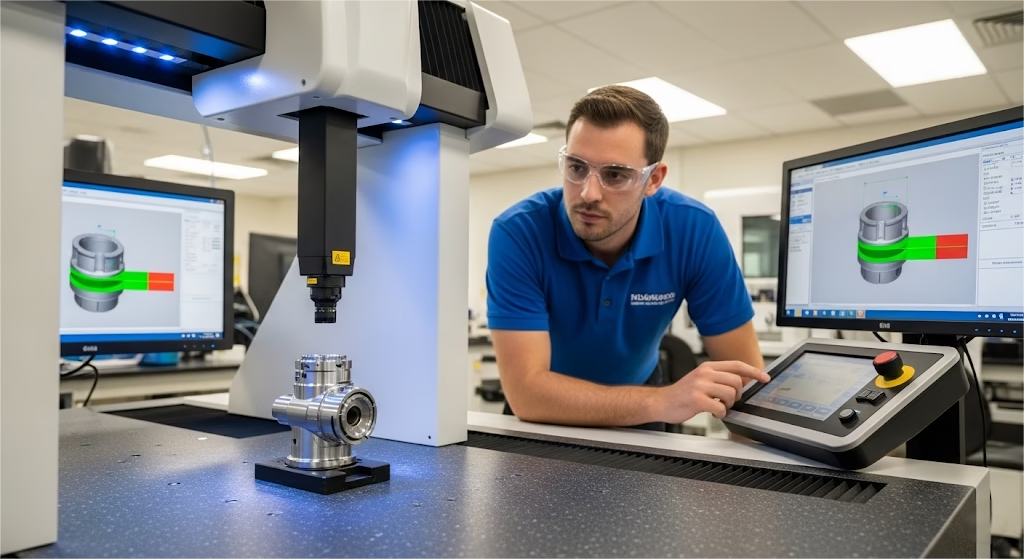

Pillar 3: The Art of Smart Tolerancing & Communication

We understand the impulse. When in doubt, you tighten the tolerance. It feels like the safe, responsible choice to ensure quality. However, this single habit is often the primary driver of unnecessary cost in small, complex turned parts. The relationship between tolerance and cost isn’t linear; it’s exponential.

Just look at the numbers. Moving from a standard, achievable tolerance to a very tight one doesn’t just increase the cost slightly; it can multiply it.

| Tolerance Range | Relative Cost Increase | Process Implication |

|---|---|---|

| ±0.1 mm (±0.004″) | 1.0x (Baseline) | Standard CNC Turning |

| ±0.025 mm (±0.001″) | 2.5x – 4.0x | Precision Turning, Climate Control |

| <±0.005 mm (<±0.0002″) | 15.0x + | Secondary Grinding/Lapping |

This is why we champion the principle of “functional tolerancing.” Instead of applying a blanket tolerance across the entire part, ask yourself: which specific surfaces are doing the critical work?

A medical startup recently learned this lesson firsthand. They designed a 50mm titanium pin and, aiming for the highest quality, specified a mirror finish and a tight tolerance of ±0.002mm across its entire length. The quote we returned was, understandably, a shock. To achieve that specification, the part required extensive secondary grinding and polishing.

Our engineers asked the key question: “Which part of this pin actually mates with another component?” It turned out to be just a 5mm section in the middle. By applying the tight tolerance only to that critical functional area and relaxing it everywhere else, we eliminated the need for secondary operations and reduced the part cost by 70%.

Before you specify a tolerance tighter than ±0.05mm, apply this simple three-question test:

- Does this surface have a precise fit with another part?

- Is it a dynamic sealing or bearing surface?

- Will loosening this tolerance cause the product to fail?

If the answer to all three is “no,” you’ve found a perfect opportunity to save money without sacrificing an ounce of performance.

The Path from Prototype to Production

Rapid prototyping has revolutionized product development, but it has also created a subtle and dangerous trap. Getting a perfectly-formed prototype in your hands is a great feeling, but it’s crucial to ask: how was it made? The truth is, a successful prototype does not guarantee a successful production run.

This is the “prototype trap.” To deliver parts quickly, prototype suppliers often use methods that are not scalable. They might use a 5-axis mill to meticulously carve a part that should be efficiently produced on a Swiss lathe, or use soft jaws and manual adjustments that are impossible in an automated production environment. These shortcuts mask the real-world challenges of heat buildup, tool wear, and material stresses that only appear during mass production.

This is why leaders in demanding fields like medical devices champion early collaboration.

As Tom O’Mara, a veteran of the medical device manufacturing industry, has consistently stated, “the most successful projects are those where the design and manufacturing teams work together from the earliest stages.”

To avoid the prototype trap, insist that your prototypes are made using the same processes intended for final production. It may add slightly to the initial cost and lead time, but it is an invaluable insurance policy against discovering a fatal design flaw after you’ve already invested in tooling and materials for a 10,000-piece order.

Conclusion: Become a More Valuable Engineer

Designing small, complex turned parts is about more than just form and function; it’s about foresight. By embracing the multiplier effect of cost, making strategic material choices, designing for “one-hit” machining, and applying intelligent tolerances, you elevate your role far beyond that of a drafter.

You become a crucial driver of project success, an innovator who controls costs, mitigates risk, and accelerates your company’s path to market. The principles in this guide are your tools to build not just better parts, but a more valuable career. When you’re ready to partner with a team that understands this philosophy from the inside out, we’re here to help.