Struggling with complex parts, multiple setups, and rising manufacturing costs? This guide provides a proven, step-by-step framework to determine if 5-axis milling is the key to unlocking higher precision, single-setup efficiency, and lower total project costs. Make the right manufacturing decision, every time.

You should use 5-axis milling when parts have complex 3D contours, undercuts, or multiple angled faces that are unreachable with 3-axis machines. It is also essential for components requiring high-precision positional accuracy (tight GD&T) that is lost through multiple setups, and when single-setup efficiency offers a lower total project cost.

Now that you know the key indicators, the real question is how to implement this strategy without falling into common traps. In this guide, we reveal the costly mistakes many companies make and provide a checklist for selecting a truly capable 5-axis partner.

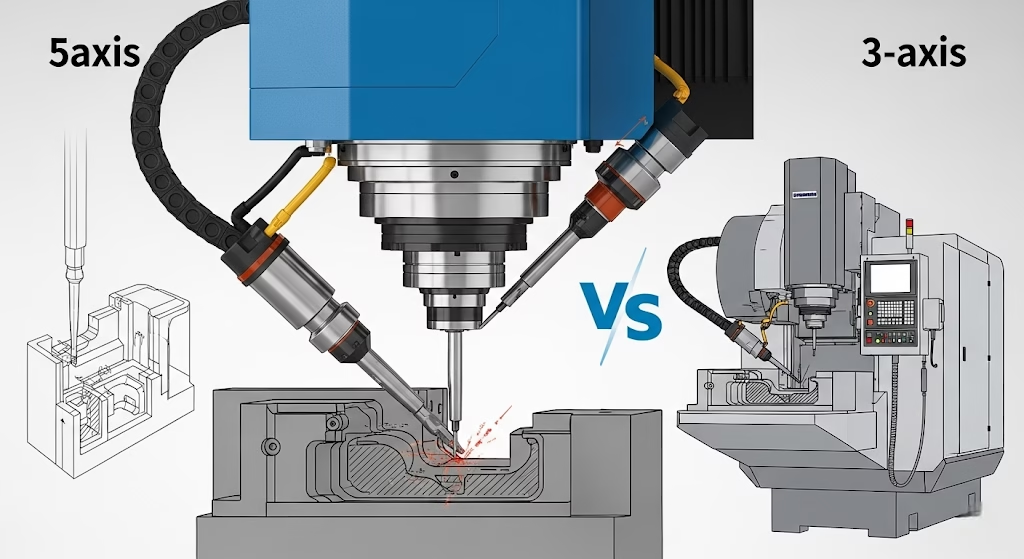

The Limitations of 3-Axis Machining

To understand when you need 5-axis, you first have to recognize the fundamental limitations of traditional 3-axis machining. A 3-axis machine operates on the X, Y, and Z axes. Imagine a drill press—the tool can only move up and down, and the workpiece can move left and right, forward and back.

While effective for simpler parts, this approach creates two significant problems when faced with complex geometry, problems that our advanced 5-axis CNC machining services are specifically designed to solve.

First is the problem of reach. With its fixed, vertical tool orientation, a 3-axis machine simply cannot “reach” certain features. Undercuts, angled holes, and the deep, curved pockets found in parts like impellers are physically inaccessible. The only way to machine these features is to stop the machine and manually re-fixture the part at a new angle—a process that is both time-consuming and a major source of error.

This leads to the second, more critical problem: accuracy decay. Every time a part is removed and re-fixtured, microscopic errors are introduced. Think of it like trying to draw a perfect circle by connecting a series of short, straight lines. Each line might be close, but the end result is never truly round.

In machining, this is known as “cumulative error” or “tolerance stacking.” While a single setup might be accurate to within 0.01 mm, after five or six setups, those tiny errors can accumulate, pushing your part’s critical dimensions out of tolerance. For any component where the precise relationship between different faces is critical, this method introduces an unacceptable level of risk.

A 3-Step Framework for Deciding on 5-Axis

So, how do you know when it’s time to make the switch? This simple three-step check will help you determine if your part is a prime candidate for 5-axis milling.

Step 1: The Geometry Test

First, examine the physical characteristics of your part. Does it contain any of the following “5-axis exclusive” features?

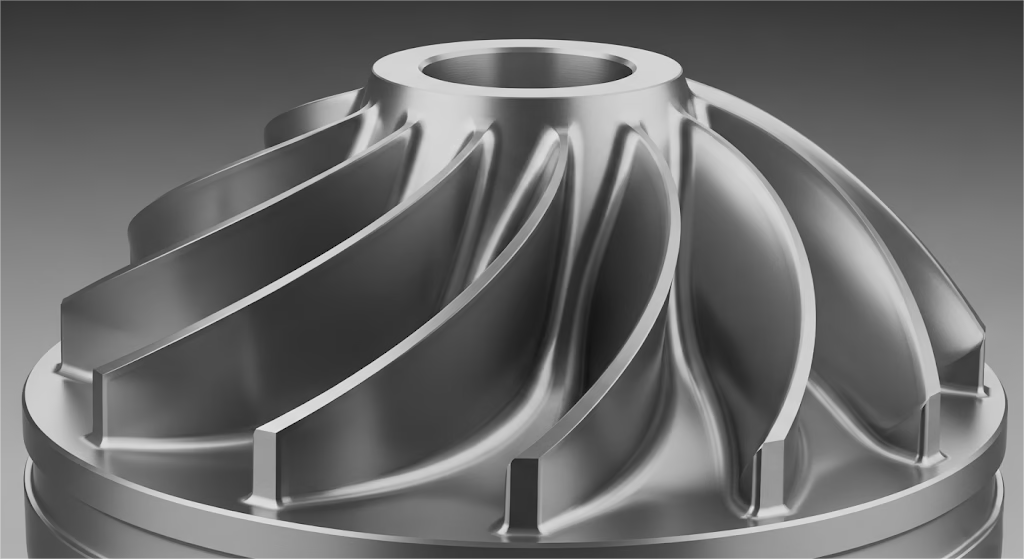

- Complex 3D Contours: Think of the sculpted, continuously curving surfaces on parts like impellers, turbine blades, or ergonomic handles. A 5-axis machine can follow these contours in one smooth, continuous toolpath, creating a superior surface finish.

- Multiple Angled Faces or Holes: Components like engine blocks or valve bodies often have holes and features on many different faces, at various angles. A 5-axis machine can orient the part to drill these holes in a single setup, whereas a 3-axis machine would require a new, complex fixture for each angle.

- Deep Pockets and Undercuts: These are features where the tool needs to enter a cavity and cut sideways, which is impossible for a fixed vertical tool. Medical implants and complex molds often feature undercuts that can only be machined by tilting the tool or the workpiece.

If your part has any of these features, 5-axis isn’t just an option; it’s a necessity.

Step 2: The Accuracy Test

Next, look at your 2D drawing to see if it requires a deep understanding of Geometric Dimensioning and Tolerancing (GD&T), with strict callouts for positional relationships like profile, position, or parallelism?

If the answer is yes, then single-setup machining is your only reliable path to success. As discussed, every time you re-fixture a part, you lose accuracy. By machining all critical features in one holding, 5-axis milling eliminates cumulative error and ensures that all features are in the correct relationship to each other, just as they were defined in the CAD model.

Step 3: The Efficiency and ROI Test

Finally, you need to ask a crucial business question: Are you chasing the lowest price-per-part or the lowest total project cost? This is where many fall into the low-quote trap.

As industry expert Mike Cope, a Senior Product Specialist at Autodesk, often emphasizes, the real revolution of 5-axis is “using it to make simpler, prismatic parts more profitably.” The true cost of a part goes far beyond the machining time.

Consider this total cost model:

| Cost Factor | Traditional 3-Axis (Multiple Setups) | 5-Axis (Single Setup) |

| Machining Cost | May seem lower per hour | May seem higher per hour |

| Custom Fixture Cost | High (potentially 3-5 unique fixtures) | Low (often one simple fixture) |

| Setup Labor Time | High (required for every re-fixturing) | Minimal (only once) |

| Scrap Rate | Higher (due to cumulative error) | Near-zero |

| Total Lead Time | Long | Short |

| Total Project Cost | High | Low |

While the hourly rate for a 5-axis machine might be higher, the dramatic savings in fixture costs, labor, and scrap rate often lead to a significantly lower total cost and a much faster time-to-market.

Preparing for a Successful 5-Axis Project

Once you’ve determined that 5-axis milling is the right choice, proper preparation is key to a successful outcome. This isn’t just about sending a file; it’s about a collaborative effort between you and your manufacturing partner.

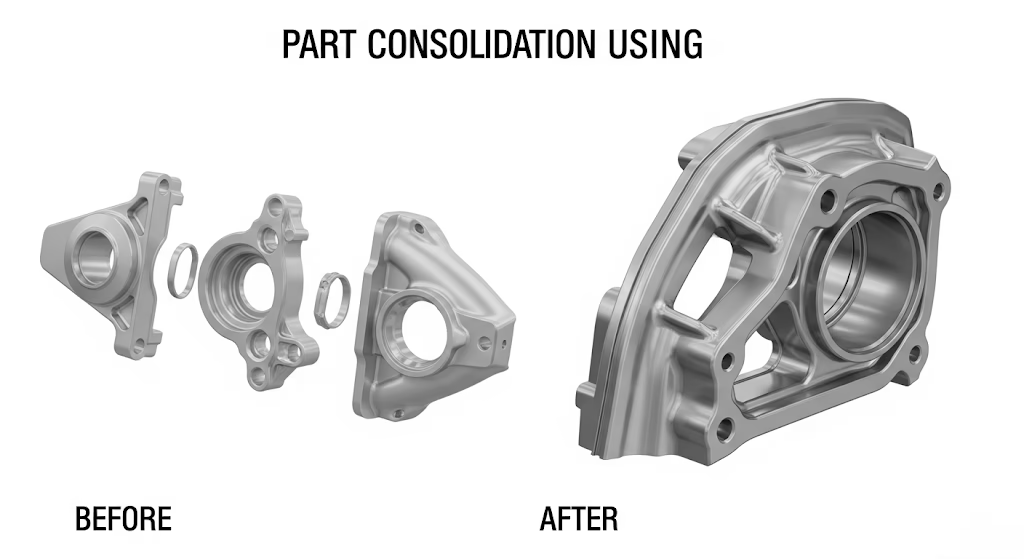

First, it is critical to optimize your design, a core part of our expert Design for Manufacturability (DFM) services.

This is where you can unlock tremendous strategic value. We worked with a competitive drone racing team whose drone arms were originally assembled from three separate carbon fiber parts. This design was heavy and had structural weak points at the joints. By collaborating with their designer, we used 5-axis capabilities to redesign the arm as a single, hollow, monolithic part.

The result? A 22% reduction in weight and a 40% increase in strength. This is the power of DFM. Ask yourself: can multiple parts in my assembly be consolidated into one stronger, lighter component?

Second, ensure your CAD model’s surface quality is pristine. For designers, this is critical. In your CAD software, a surface transition that is merely tangent (G1 continuity) might look smooth, but to a high-speed machine tool, it’s a sharp corner. The machine will decelerate, pivot, and accelerate, leaving a visible mark on the finished part.

To achieve a flawless, “Class-A” surface finish, all critical aesthetic surfaces must have curvature continuity (G2). A brief DFM review with your manufacturing partner early on can save weeks of revisions.

Finally, prepare a professional Request for Quote (RFQ) package. To get an accurate and fast quote, provide your supplier with:

- A 3D model in a universal format like STEP or X_T.

- A 2D drawing that clearly calls out critical tolerances, materials, and any required heat treatment or surface finishes.

- The required quantity and desired lead time.

How to Select a True 5-Axis Partner

Choosing the right supplier is just as important as choosing the right process. The industry secret is that a company’s capability is like an iceberg: the machine itself is just the 10% you can see, while the crucial 90%—the software, process knowledge, and talent—lies hidden beneath the surface. Owning a 5-axis machine doesn’t guarantee expertise.

To find a partner with true deep capability, ask these three questions:

- “What is the experience level of the programmer who will handle my project?”

The soul of 5-axis machining is the programmer. An experienced expert can create efficient, safe toolpaths for the most complex parts, while a novice can lead to delays and errors. - “Which CAM software do you use for 5-axis programming?”

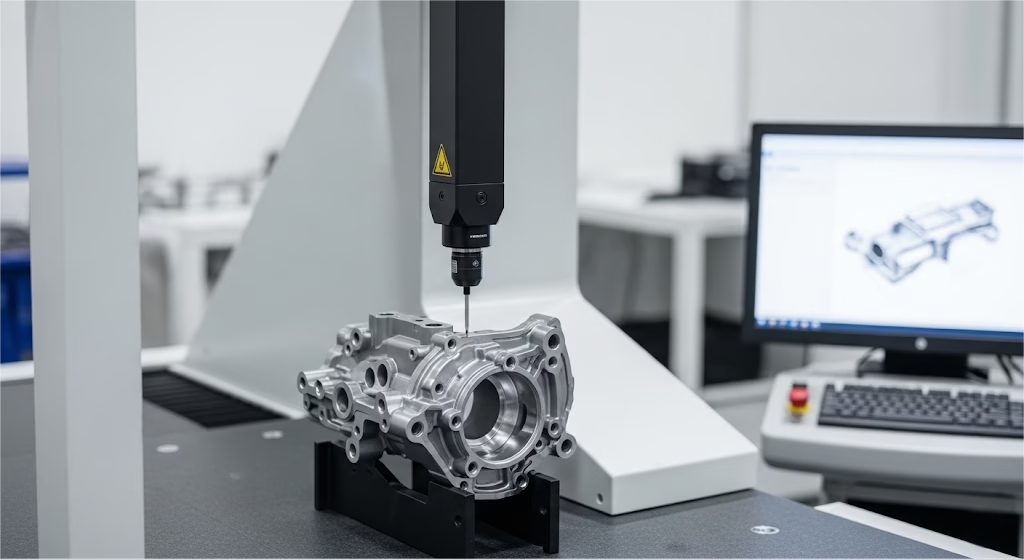

Top-tier shops invest in advanced software like PowerMill or Hypermill. This reflects a commitment to quality and handling complexity. - “How do you verify final part accuracy?”

The ability to machine a complex part is useless without the ability to inspect it. A credible partner must have high-end inspection equipment, like a Coordinate Measuring Machine (CMM), and be able to provide detailed inspection reports.

Conclusion: From Technical Choice to Strategic Advantage

Ultimately, the decision to use 5-axis milling is more than a technical choice—it’s a strategic investment in your product’s future.

It provides designers with the freedom to innovate without compromise, gives engineers the control to guarantee quality and precision, and offers managers a powerful tool to reduce total project costs and accelerate time-to-market. By understanding when and why to leverage this advanced technology, you can build a significant competitive advantage.

If you have a complex part that fits the criteria we’ve discussed, our team at Zenithin is here to help. Upload your design today for a confidential and complimentary manufacturability analysis from our experienced 5-axis engineers.