Precision CNC Drilling Service

Achieve flawless assembly with our comprehensive drilling services, providing everything from simple pilot holes to precisely tapped and reamed bores for guaranteed component fit and function.

- High Positional Accuracy

- Versatile Hole Types

- High-Volume Efficiency

A Complete Hole-Making Solution

Our capabilities extend beyond standard drilling to provide a full spectrum of hole-making and finishing services to meet all your functional requirements. For an in-depth comparison of advanced techniques, read our guide to reaming vs. boring.

The Strategic Advantage of Reliable Drilling

Accurate and reliable hole-making is fundamental to the success of any mechanical assembly. Partner with us to ensure your components fit together perfectly, every time.

Our CNC Drilling Capabilities at a Glance

The table below outlines our standard capabilities. If your project has requirements that go beyond these specifications, please contact our engineering team.

|

Feature

|

Zenithin's Specification

|

|---|---|

|

Certifications |

ISO 9001:2015 |

|

Hole Types |

Through-hole, Blind-hole, Threaded, Reamed, Counterbored |

|

Hole Diameter Range |

Ø0.5mm - Ø50mm |

|

Positional Accuracy |

±0.02mm |

|

Max Drilling Depth |

Up to 20x Diameter (material dependent) |

|

Thread Types |

Metric (M2-M30), UNC/UNF |

|

Key Materials |

Aluminum, Steel, Stainless Steel, Brass, Copper, Engineering Plastics |

Proven Results in Complex Hole Patterns

From high-density threaded arrays in advanced polymers to intricate hole patterns on curved surfaces, our precision drilling services deliver reliable solutions for the most demanding applications. Explore some of our work below.

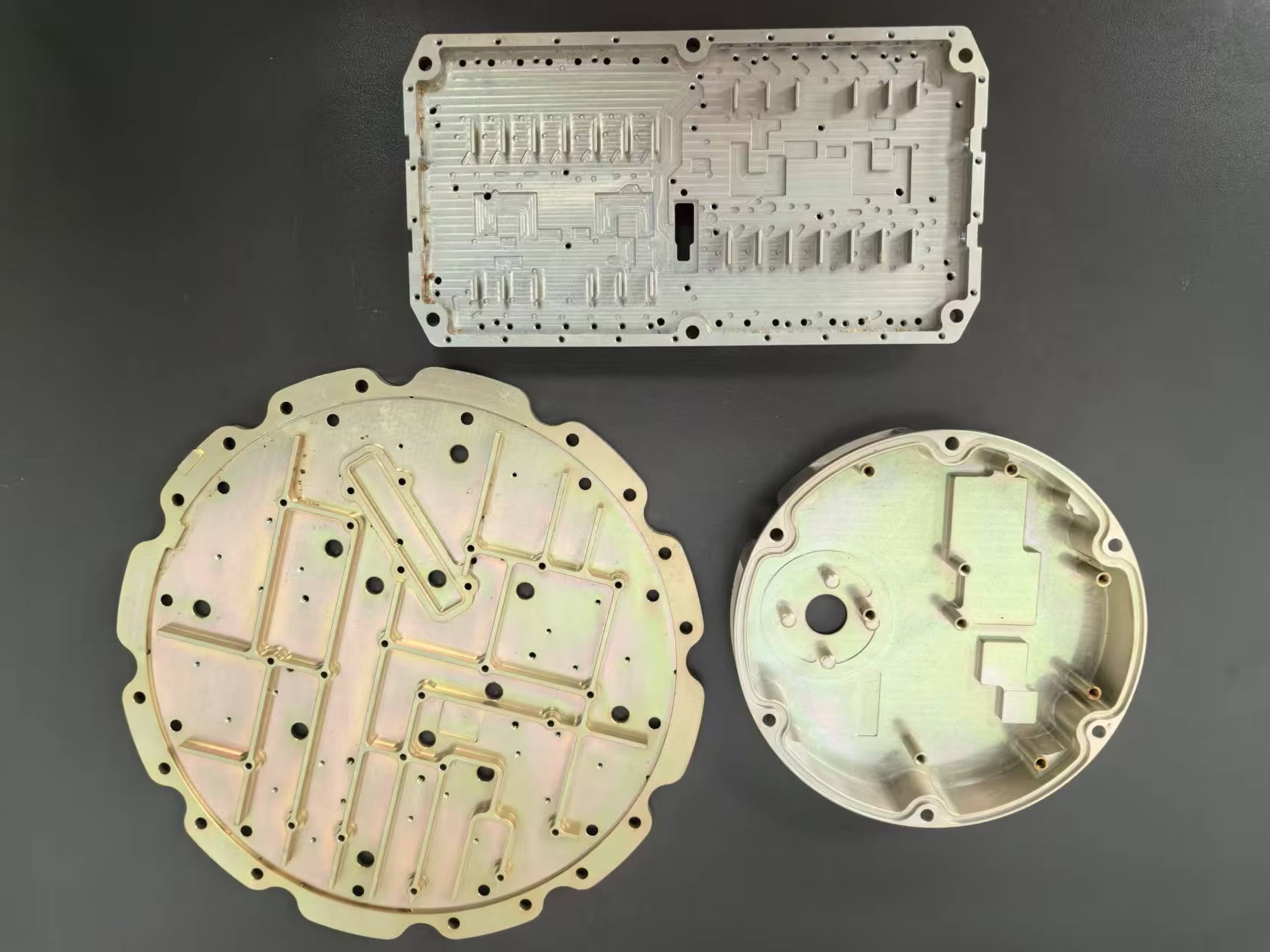

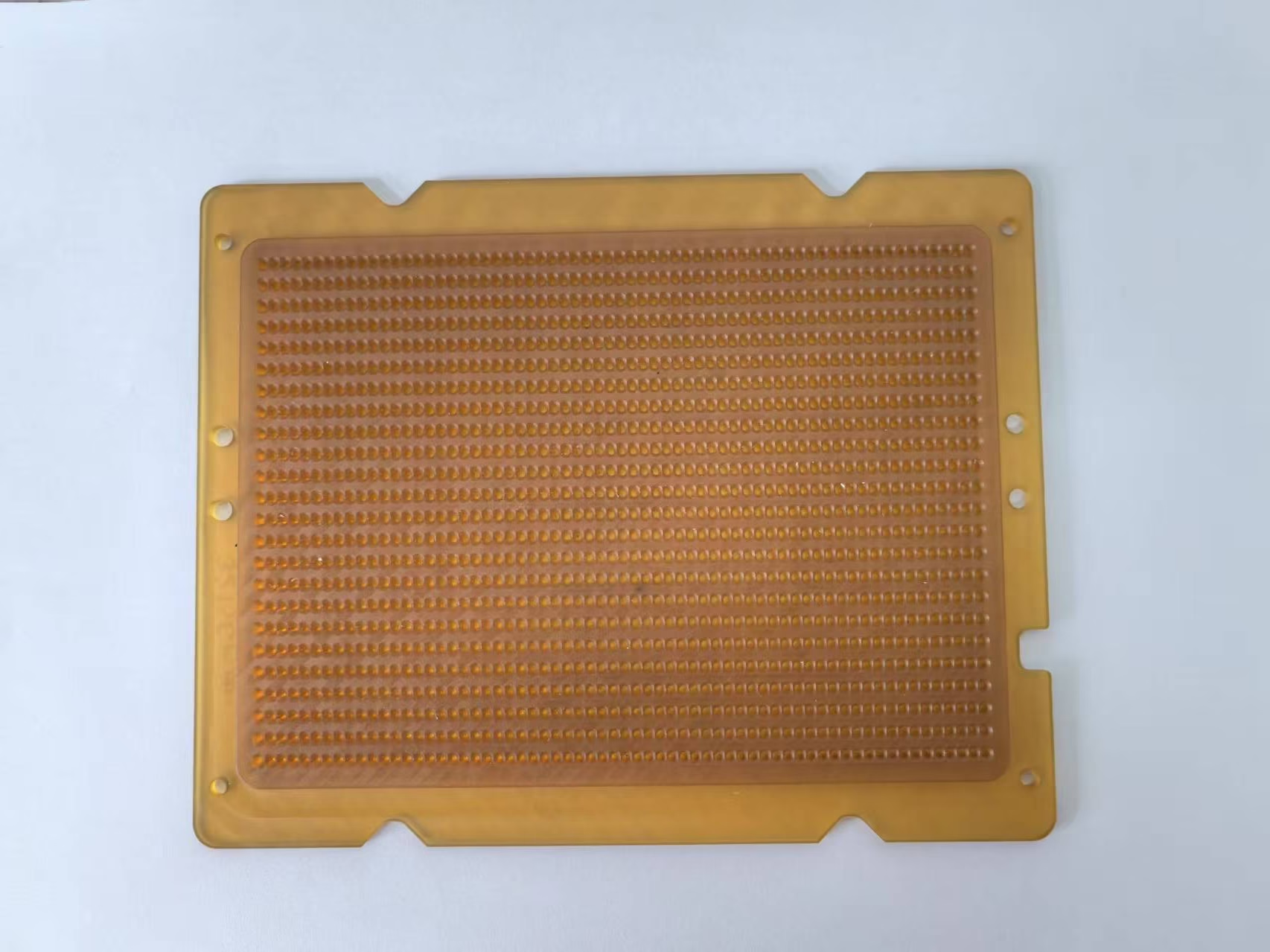

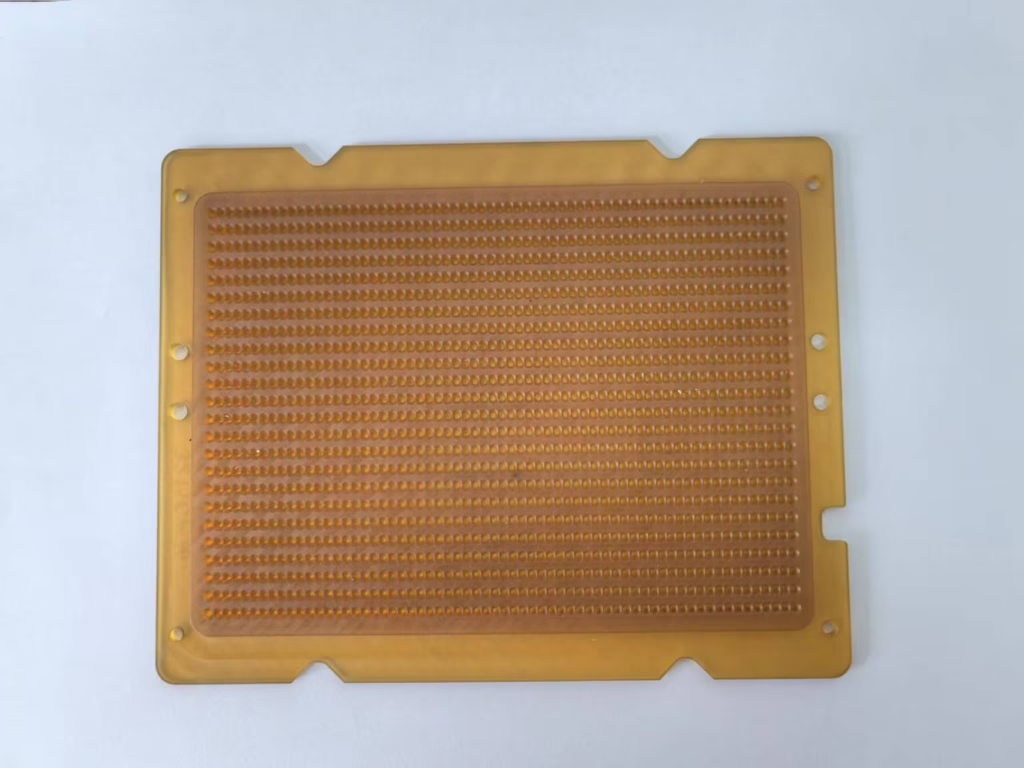

High-Density PEEK Loading Tray

A PEEK loading tray featuring over 1000 precisely tapped M3 holes, produced with high-efficiency multi-spindle drilling.

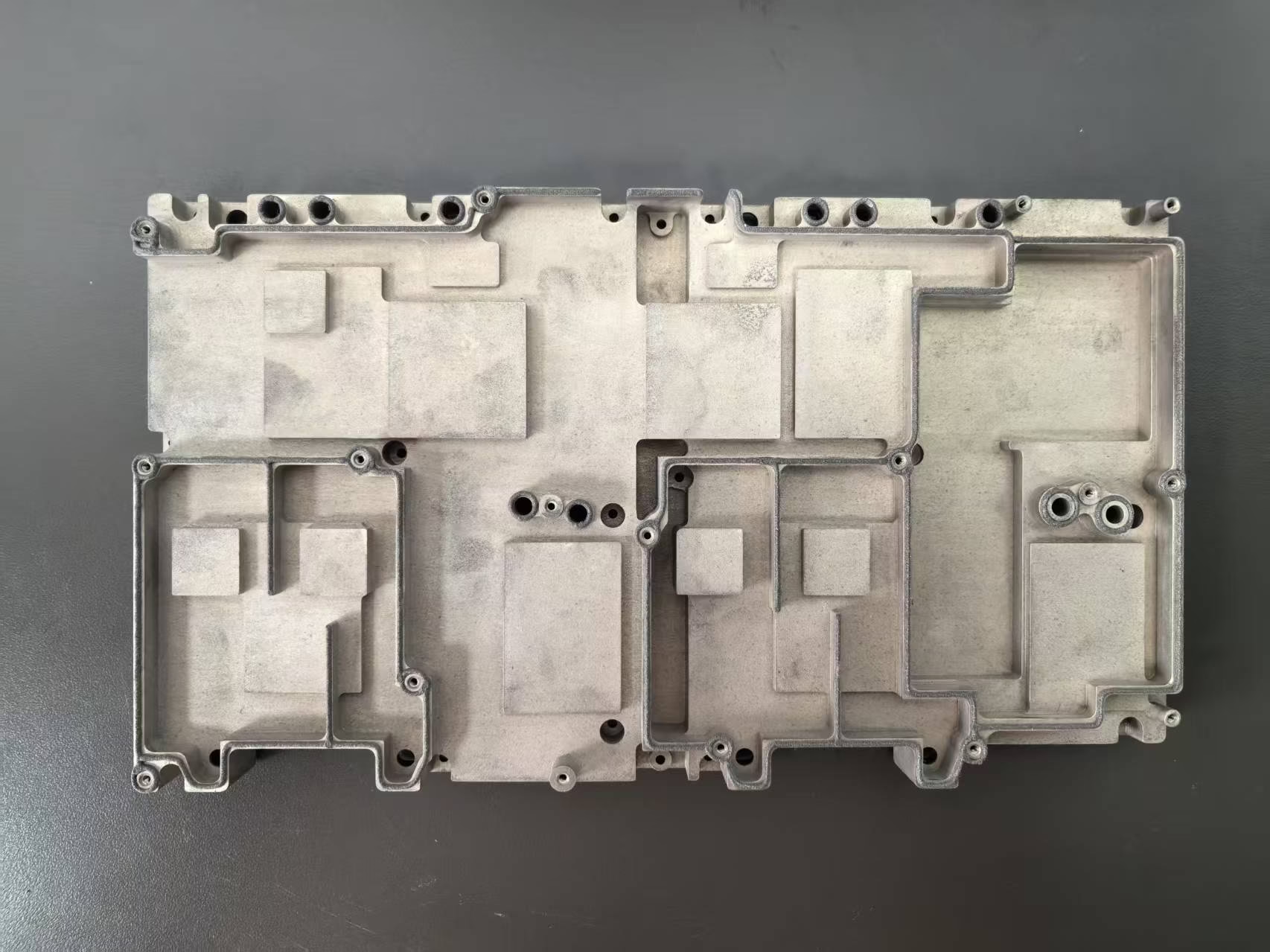

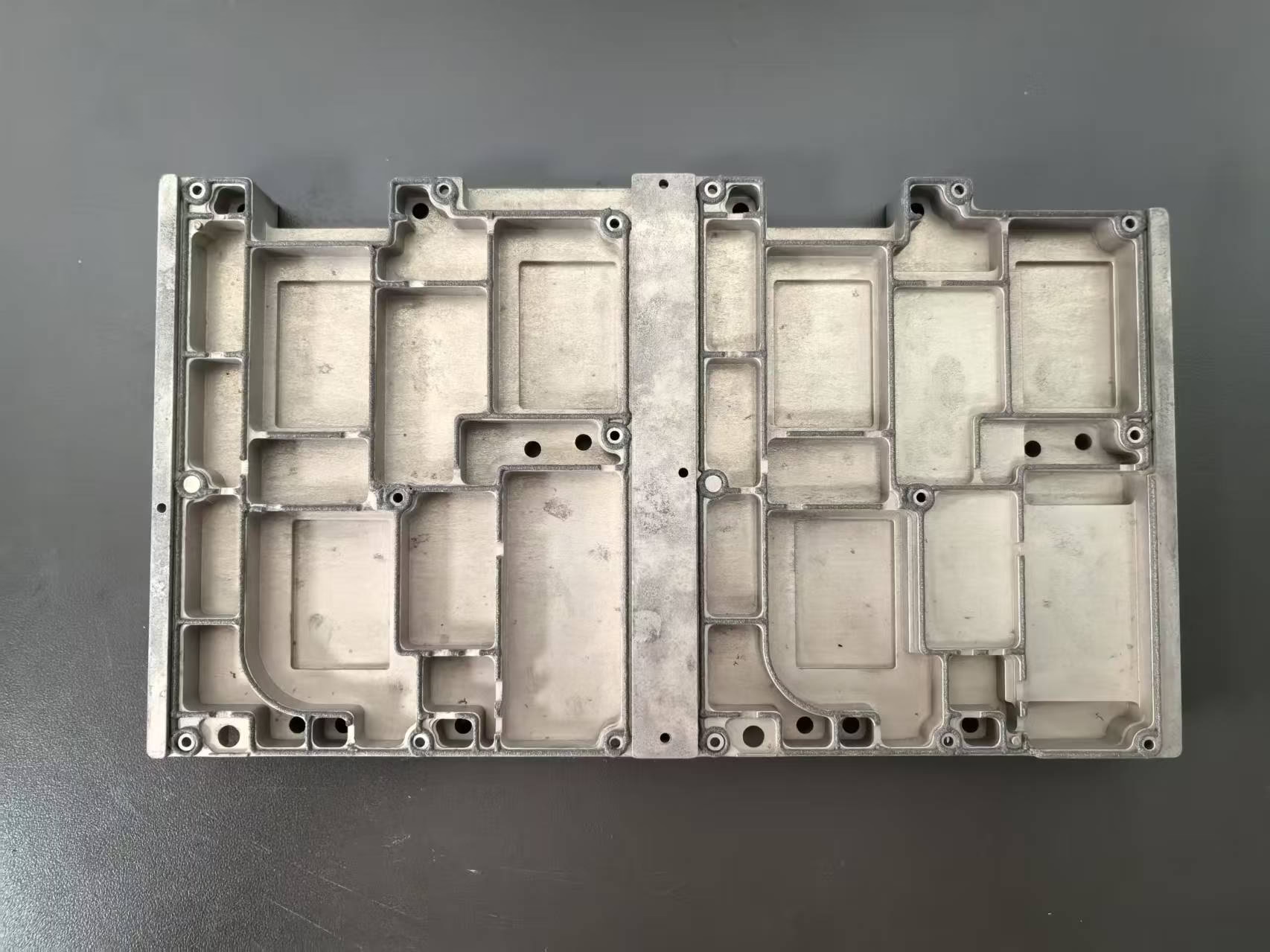

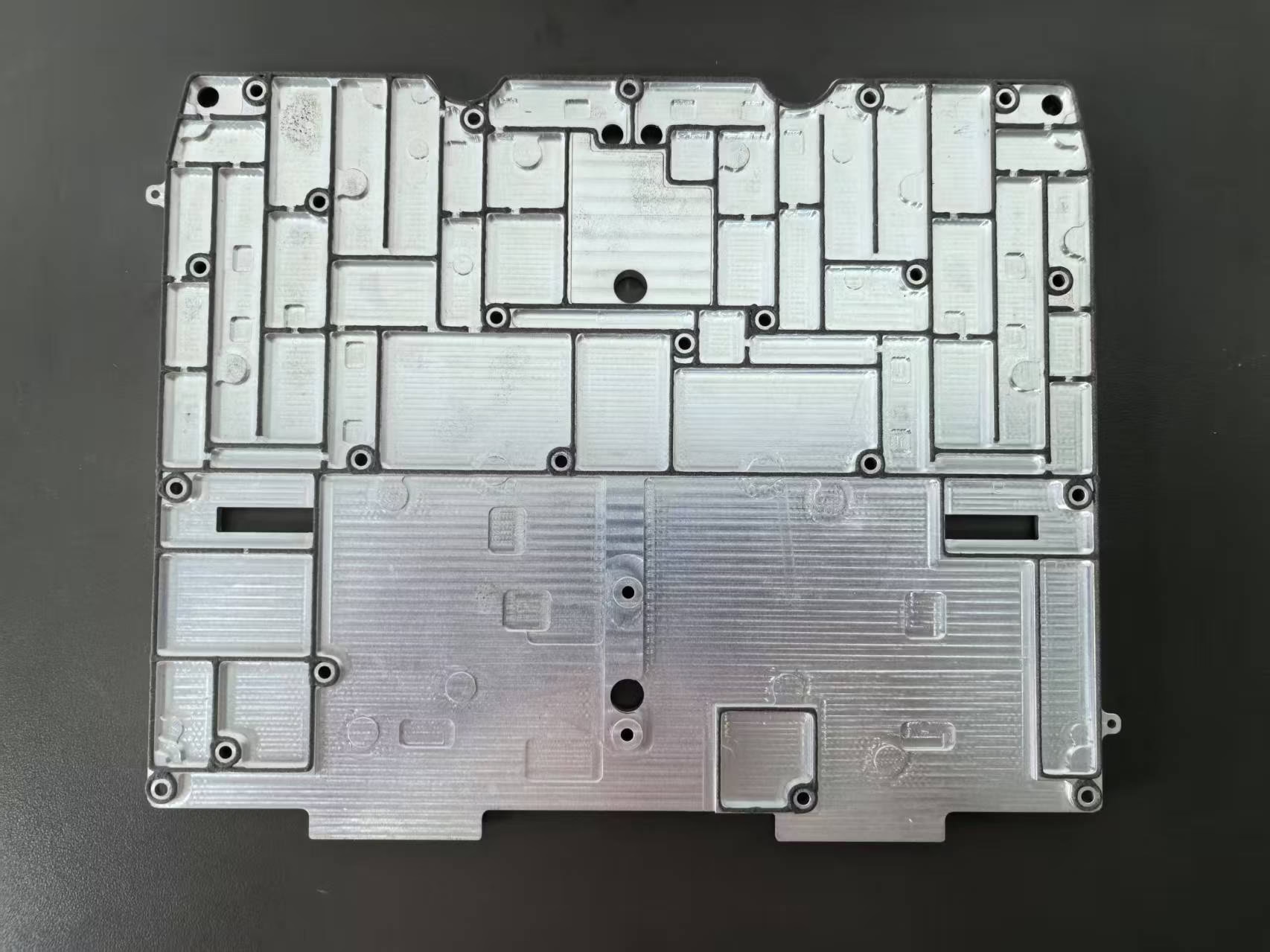

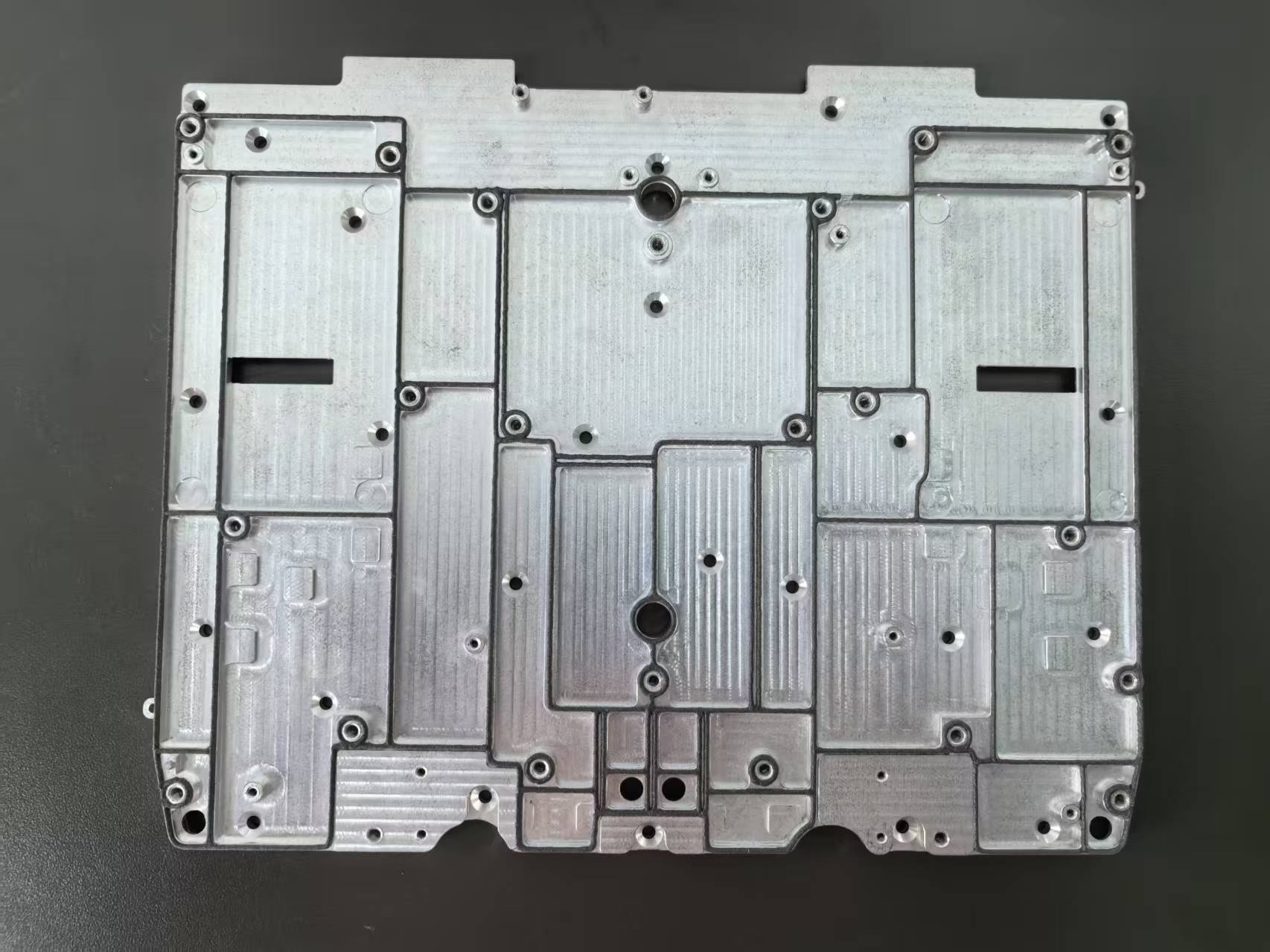

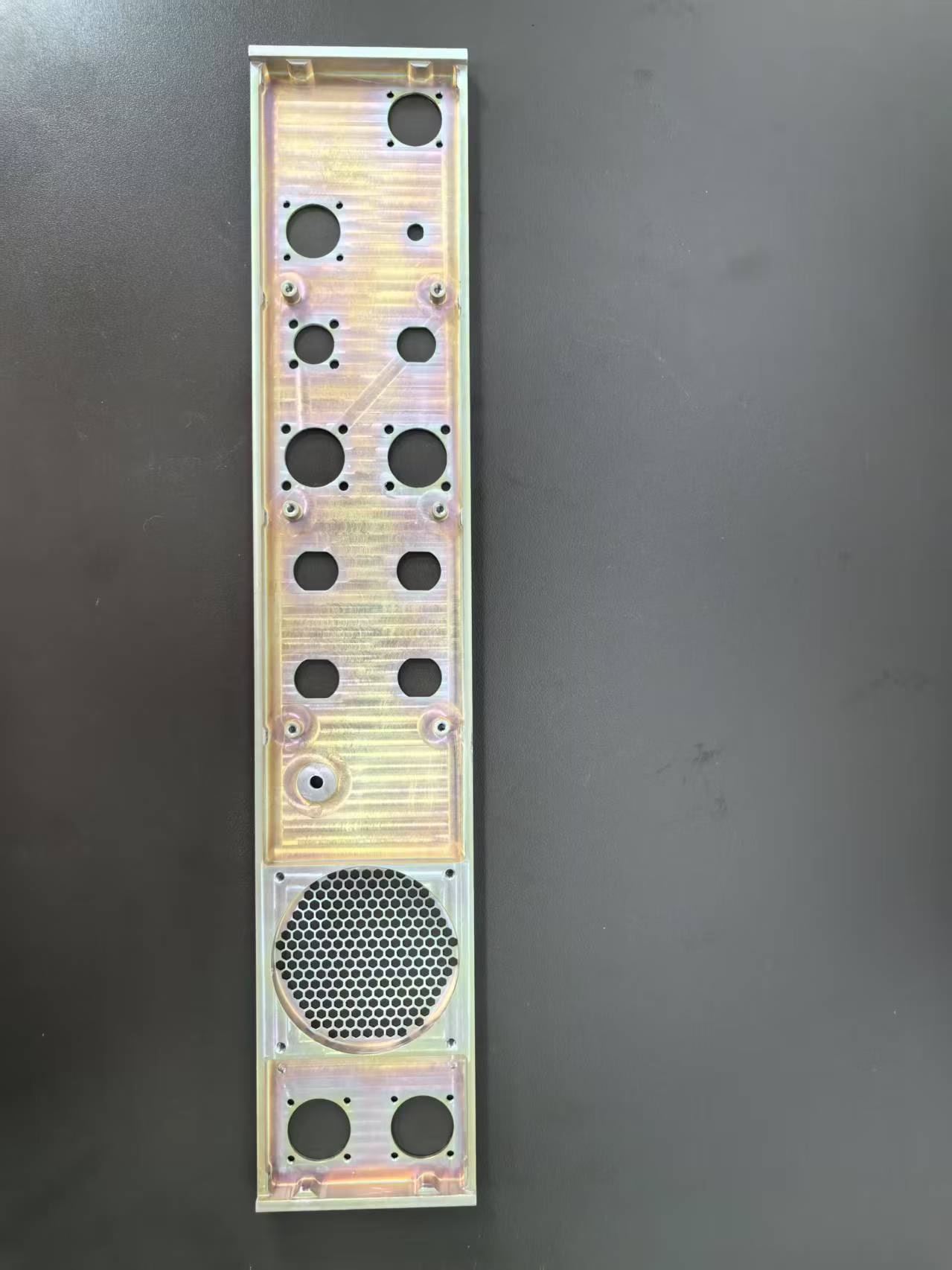

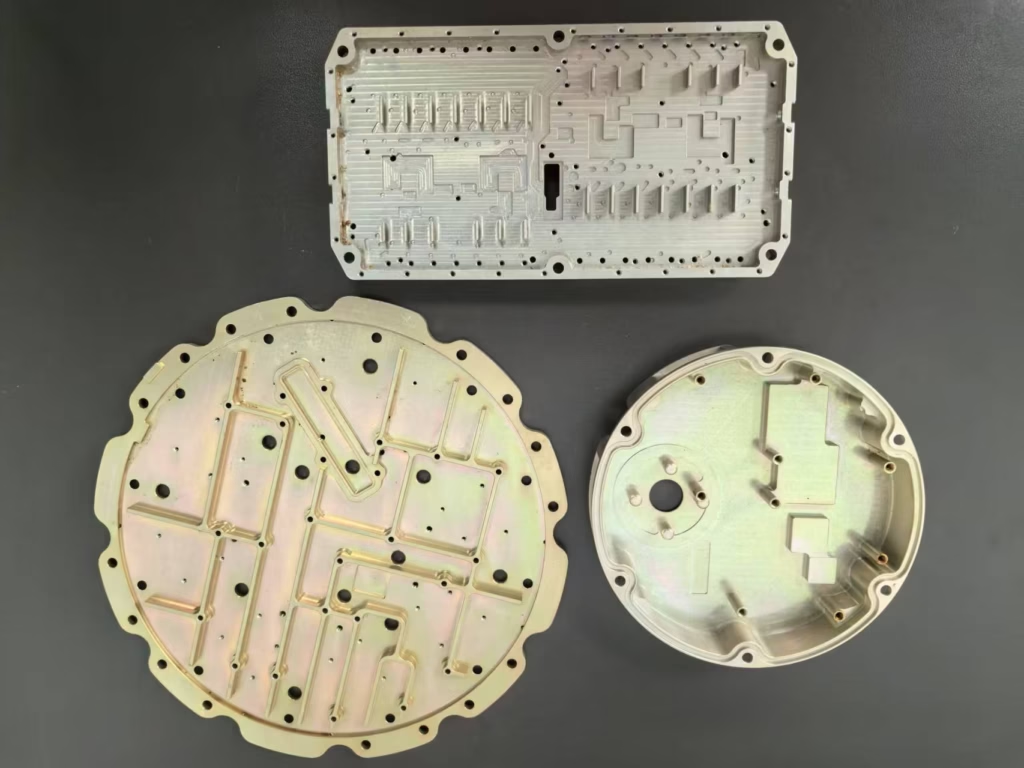

Magnesium Alloy Shield Case

A lightweight magnesium alloy shield case with a complex pattern of drilled and tapped holes, finished with a durable hard anodizing.

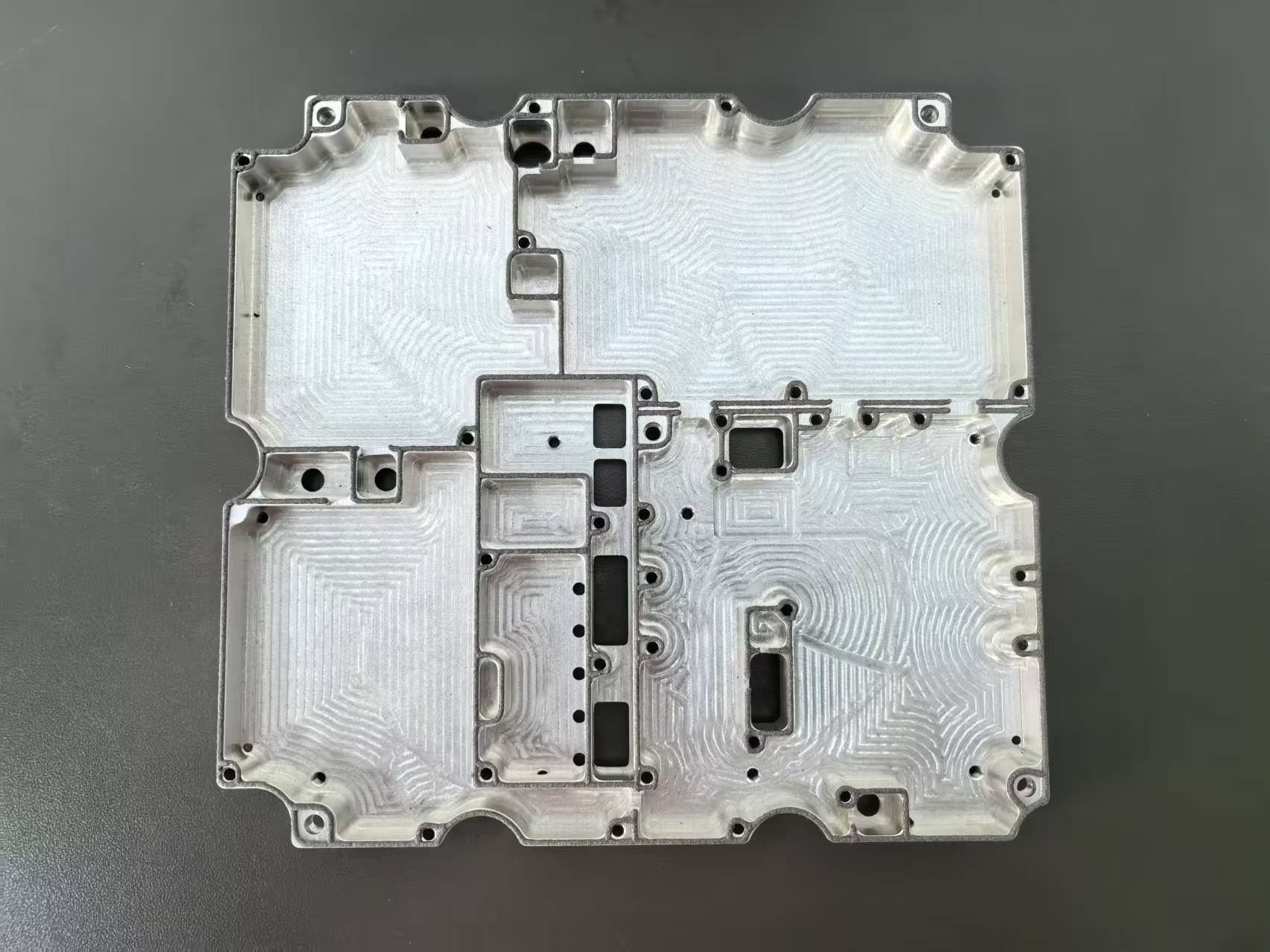

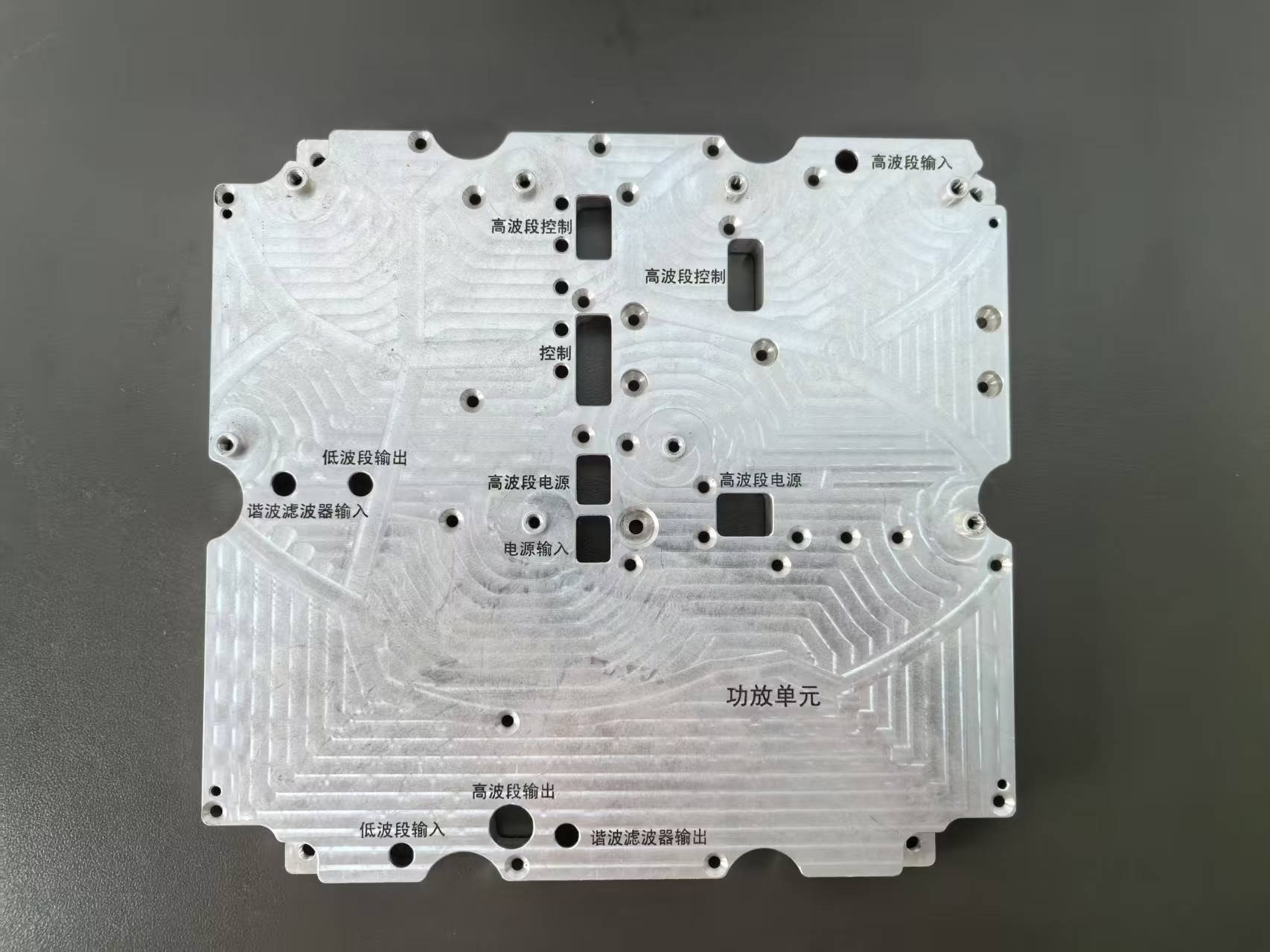

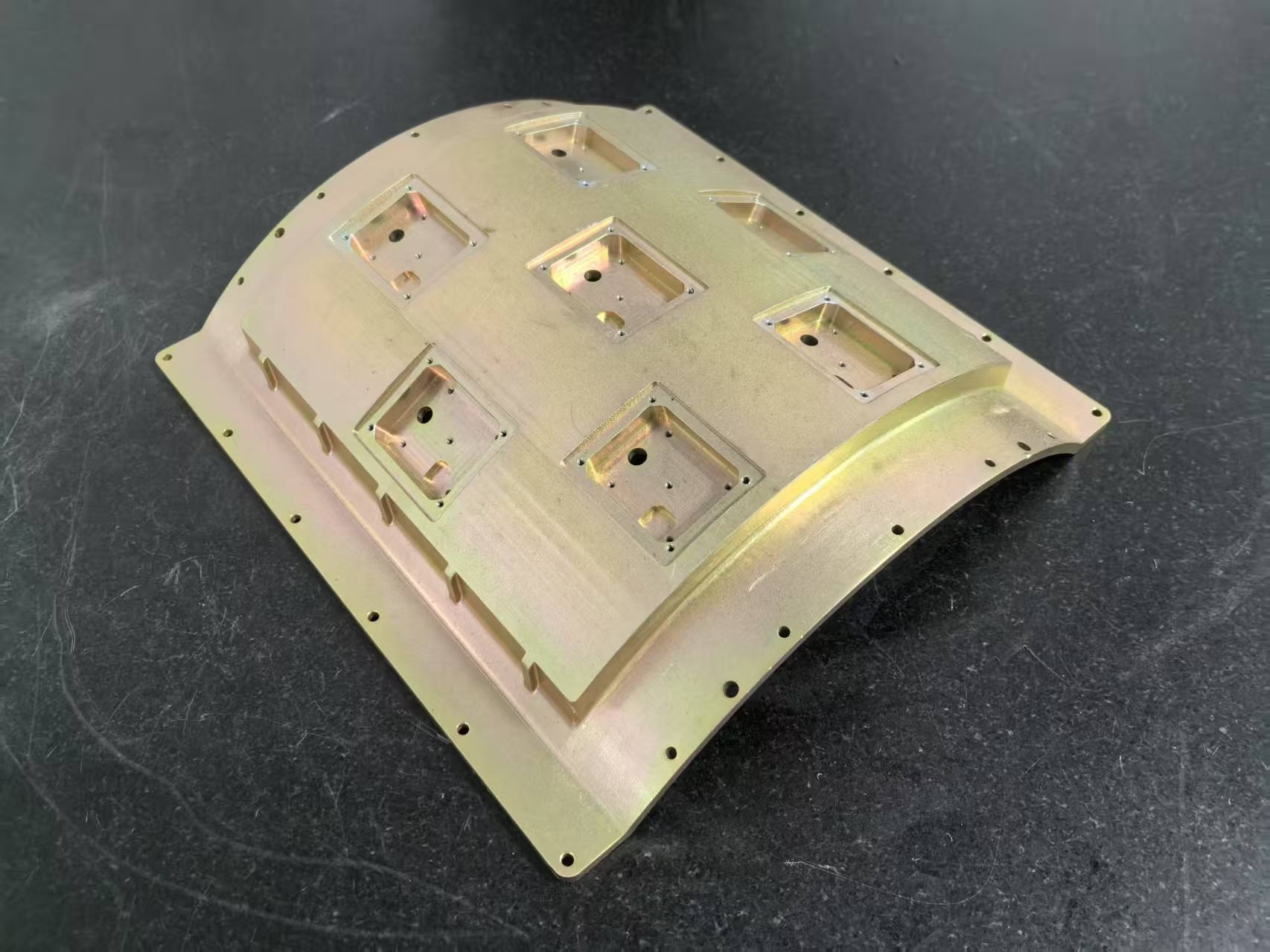

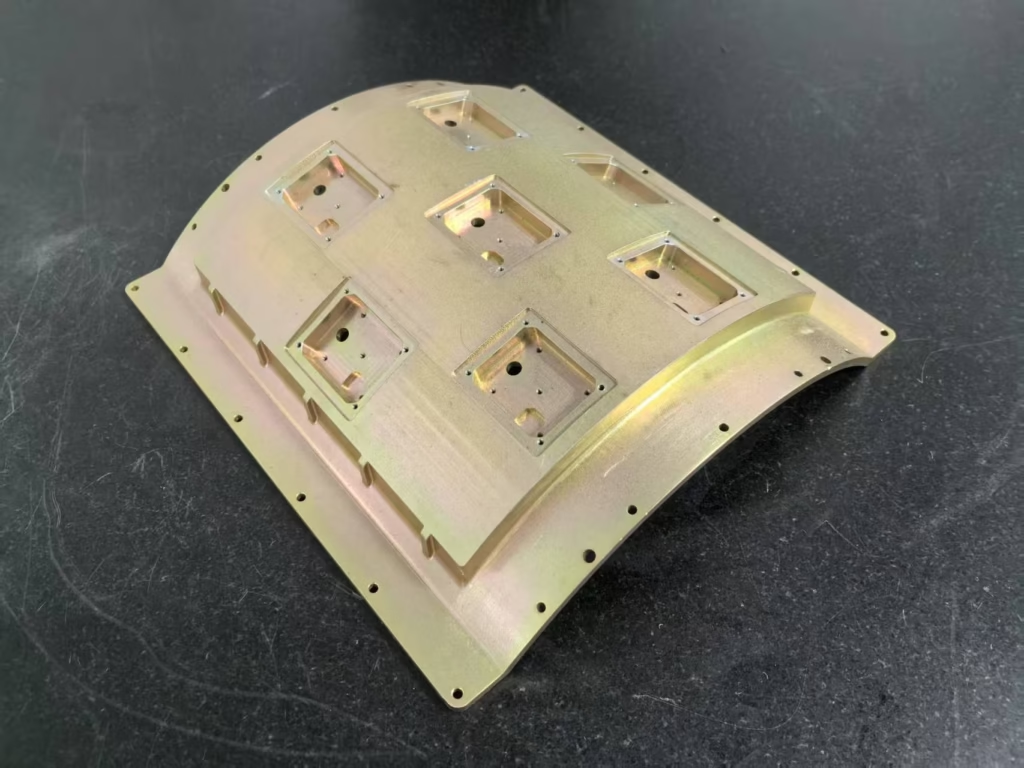

Curved Surface Shield Disc

This magnesium alloy disc required advanced 5-axis positioning to drill perfect, perpendicular holes on its complex curved surface.

Impressed by Our Work? Let's Build Yours

We are ready to apply the same precision and commitment to quality to your project. Upload your design files to get started with a free, no-obligation quote from our expert engineers.

PRECISION

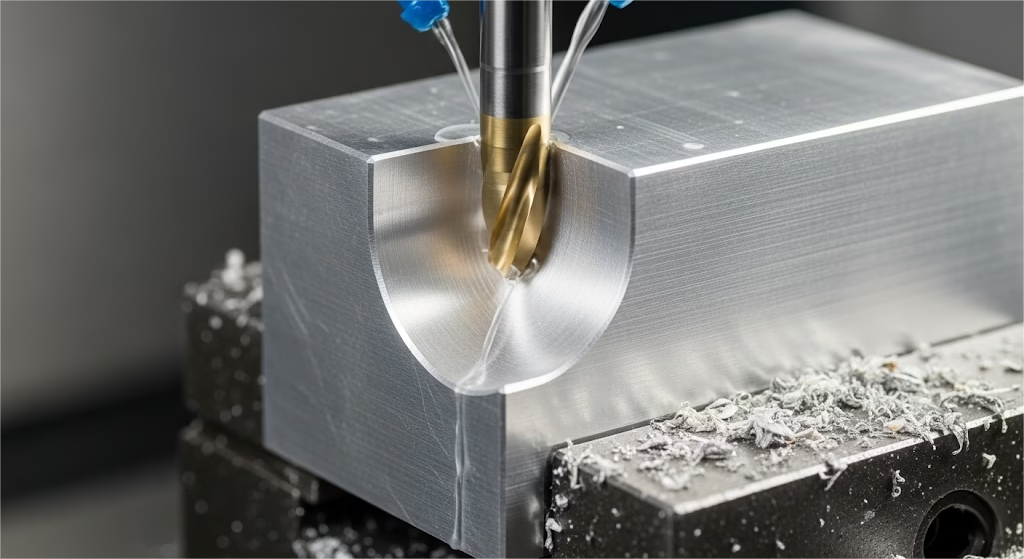

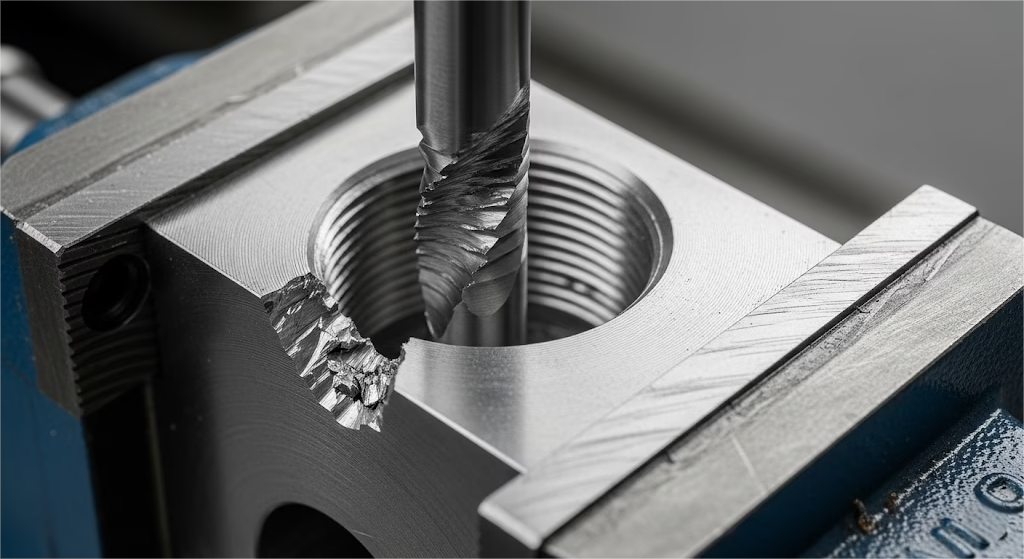

Powered by Advanced CNC Technology

We utilize modern CNC machining centers to perform all drilling operations. This automated approach guarantees higher accuracy and consistency than manual methods.

Drilling machine for drilling processing

Drilling machine for drilling processing

Drilling machine for drilling processing

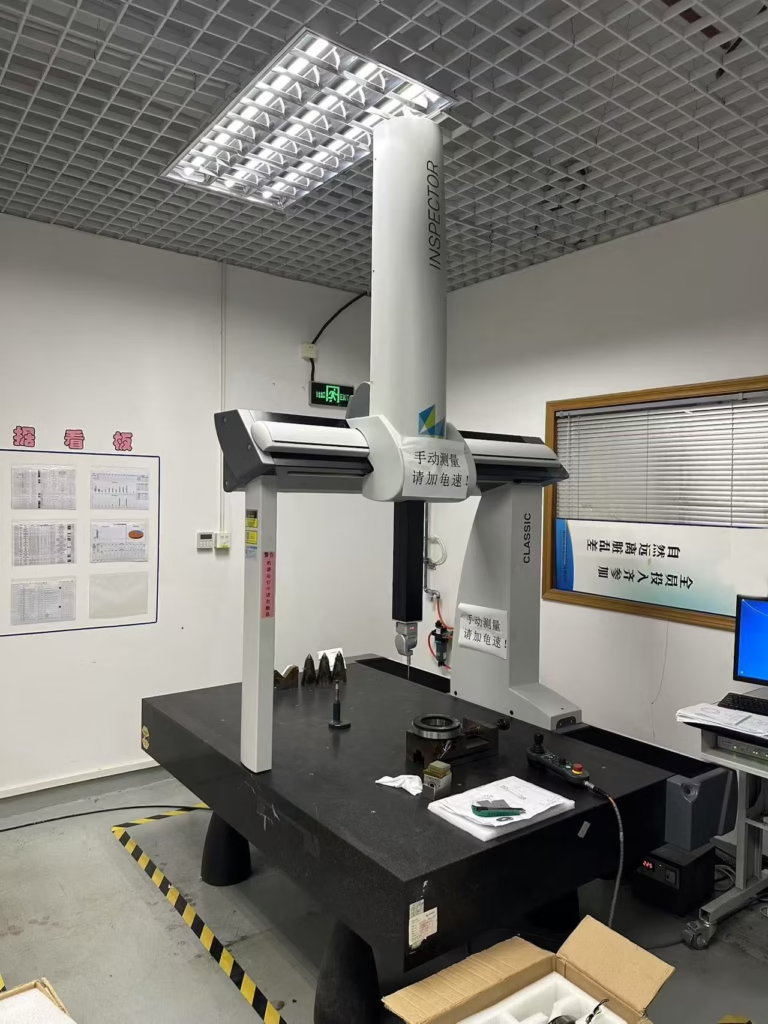

Precision, Verified.

We don’t just drill holes; we verify them. Every critical hole is checked on our high-precision CMM for positional accuracy and with calibrated pin gauges for diametrical tolerance.

High-precision Digital Height Gauge

Three-dimensional Measuring Instrument

Three-dimensional Measuring Instrument

Your Drilling Questions, Answered

Find answers to common technical questions about our CNC drilling services below.

Drilling creates the initial hole. Reaming is a secondary finishing process that enlarges the hole slightly to achieve a much tighter diameter tolerance and a smoother internal surface.

Yes. For hardened materials, we don't use standard cutting taps. Instead, we utilize stronger "form taps" or a process called "thread milling" to create precise and durable threads.

Our standard positional tolerance for CNC drilled holes is ±0.02mm. Tighter tolerances can often be achieved, so please specify your critical requirements on your drawing for our engineering review.

As a general rule, we can reliably drill to a depth of 10 times the hole's diameter (10:1). For specific applications, using advanced "peck drilling" cycles and high-pressure coolant, we can often achieve deeper ratios. We recommend consulting with us for any deep-hole requirements.

Yes. Using our 4-axis and 5-axis CNC machines, we can accurately drill holes at various angles relative to the primary surfaces. This ensures the hole is perfectly perpendicular to the local surface, which is critical for many advanced applications.

For maximum clarity, please use hole callouts that specify all features in one note (e.g., diameter, depth, counterbore size, thread type). Always dimension hole locations from clear datums (A, B, C). A well-defined drawing prevents errors and speeds up quoting. If you're unsure, feel free to send us your preliminary design for DfM (Design for Manufacturing) feedback.

Ready to Tackle Your Most Complex Project?

Our team thrives on complexity. From aerospace components to medical devices, we leverage advanced 5-axis technology to turn your most challenging designs into reality.

Submit your files for a comprehensive quote and an expert engineering review.

Take the first step today !

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.