CNC Grinding Service

Achieve sub-micron tolerances, superior surface finishes, and flawless geometric accuracy. We are your ISO 9001 certified partner for the most demanding grinding applications.

- Tight Tolerance Guaranteed

- Complex Geometry Capability

- Rapid Process Planning & Production

A Complete Range of Grinding Solutions

From cylindrical and surface to internal and centerless grinding, we have the specialized technology to meet your exact specifications. Explore our core services below.

Your Strategic Advantage with Our Grinding Expertise

Go beyond standard machining. Our grinding expertise provides key advantages in precision, material capability, and production efficiency, directly contributing to a superior final product.

Our Grinding Capabilities at a Glance

We are equipped to handle a wide range of demanding grinding projects. The table below outlines our standard capabilities for precision, materials, and the key industries we serve.

|

Feature

|

Zenithin's Specification

|

|---|---|

|

Certifications |

ISO 9001:2015 |

|

Grinding Types |

Cylindrical (External/Internal), Surface, Centerless |

|

Max Part Size |

Cylindrical: Ø300 x 1000 mm | Surface: 600 x 400 mm |

|

Highest Tolerance |

±0.001mm (1μm) |

|

Best Surface Finish |

|

|

Key Materials |

Hardened Steels (HRC60+), Tool Steel, Stainless Steel, Aluminum, Carbides |

|

Industries Served |

Aerospace, Medical, Automotive, Tool & Die, Robotics |

Proven Results Across Demanding Industries

From hardened tool steel for the automotive sector to high-precision medical components, see how our grinding expertise delivers tangible results.

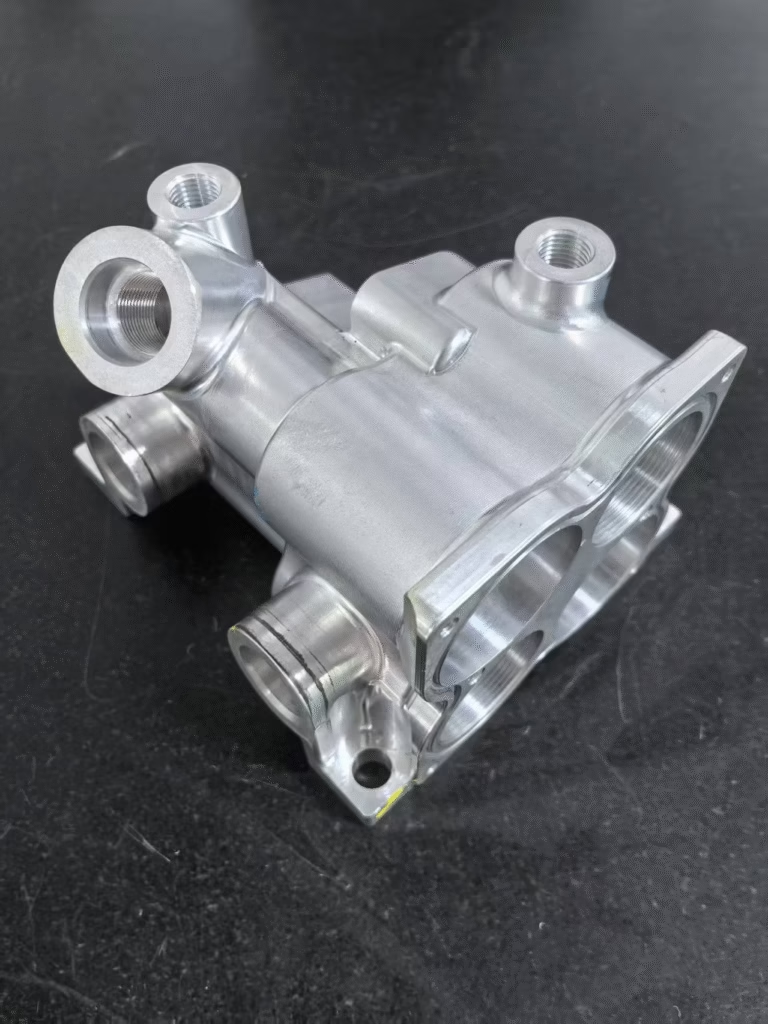

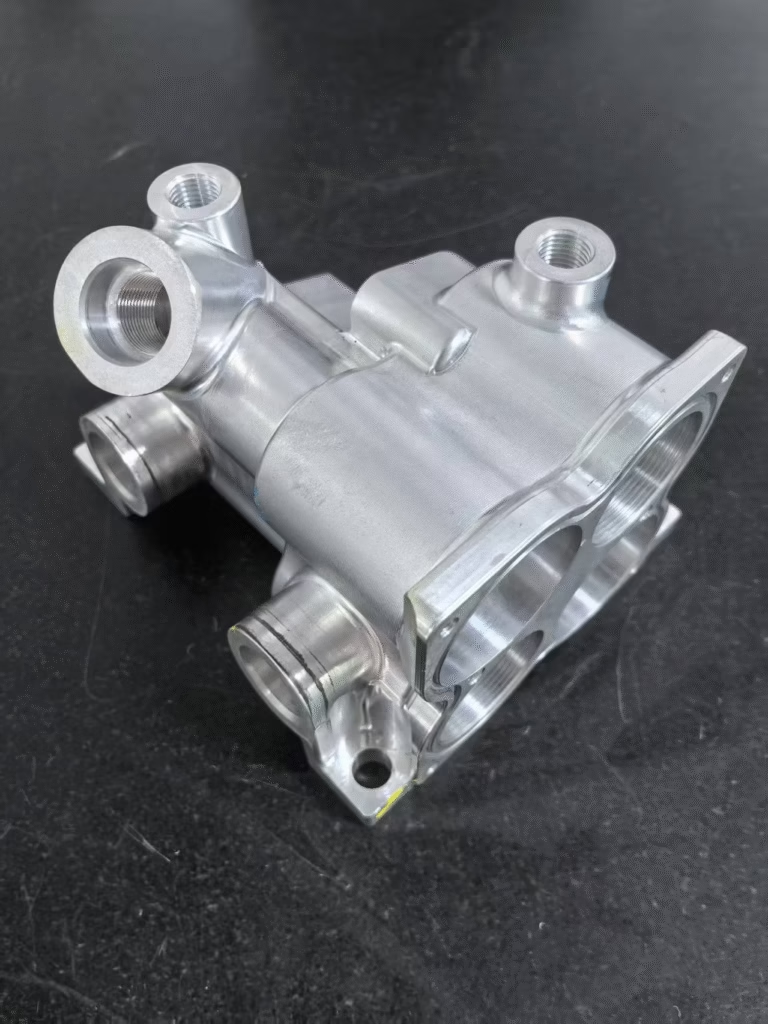

Complex Aluminum Housing

A complex housing produced with 5-axis CNC from Aluminum 7075 , featuring tight H7 tolerances and a clear anodized finish.

Complex Aluminum Housing

A complex housing produced with 5-axis CNC from Aluminum 7075 , featuring tight H7 tolerances and a clear anodized finish.

- Teléfono:+1 (859) 254-6589

- Correo electrónico:[email protected]

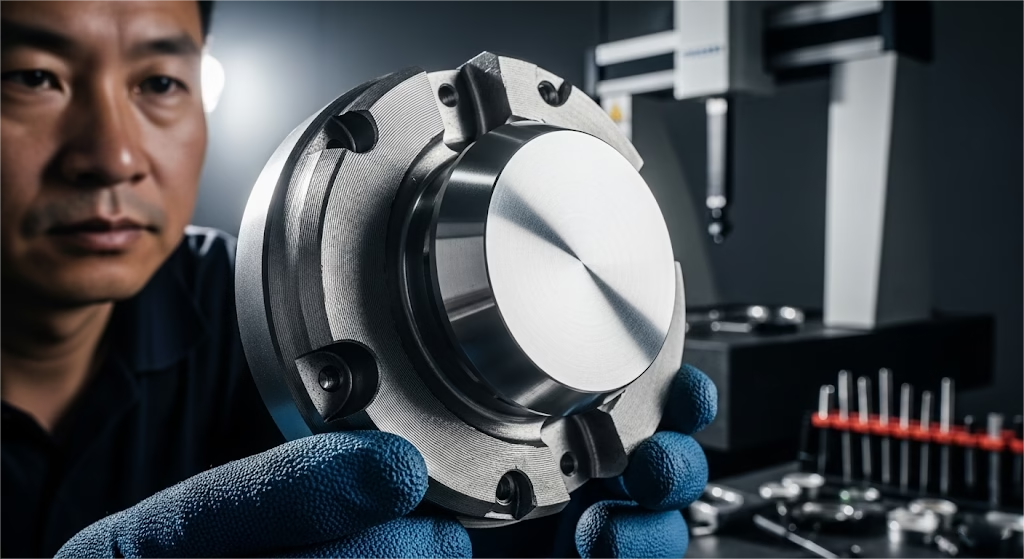

Custom Chrome-Plated Steel Flange

Multi-process machined from 45# steel (turning, CNC, drilling) and finished with chrome plating for superior wear resistance.

Custom Chrome-Plated Steel Flange

Multi-process machined from 45# steel (turning, CNC, drilling) and finished with chrome plating for superior wear resistance.

- Teléfono:+1 (859) 254-6589

- Correo electrónico:[email protected]

5-Axis Milled Aluminum Enclosure

A 5-axis milled enclosure in Aluminum 6061 , holding strict geometric tolerances (⊥/▱/◎ 0.01mm) for perfect alignment.

5-Axis Milled Aluminum Enclosure

A 5-axis milled enclosure in Aluminum 6061 , holding strict geometric tolerances (⊥/▱/◎ 0.01mm) for perfect alignment.

- Teléfono:+1 (859) 254-6589

- Correo electrónico:[email protected]

Impressed by Our Work? Let's Build Yours

We are ready to apply the same precision and commitment to quality to your project. Upload your design files to get started with a free, no-obligation quote from our expert engineers.

PRECISION

Powered by Precision Grinding Technology

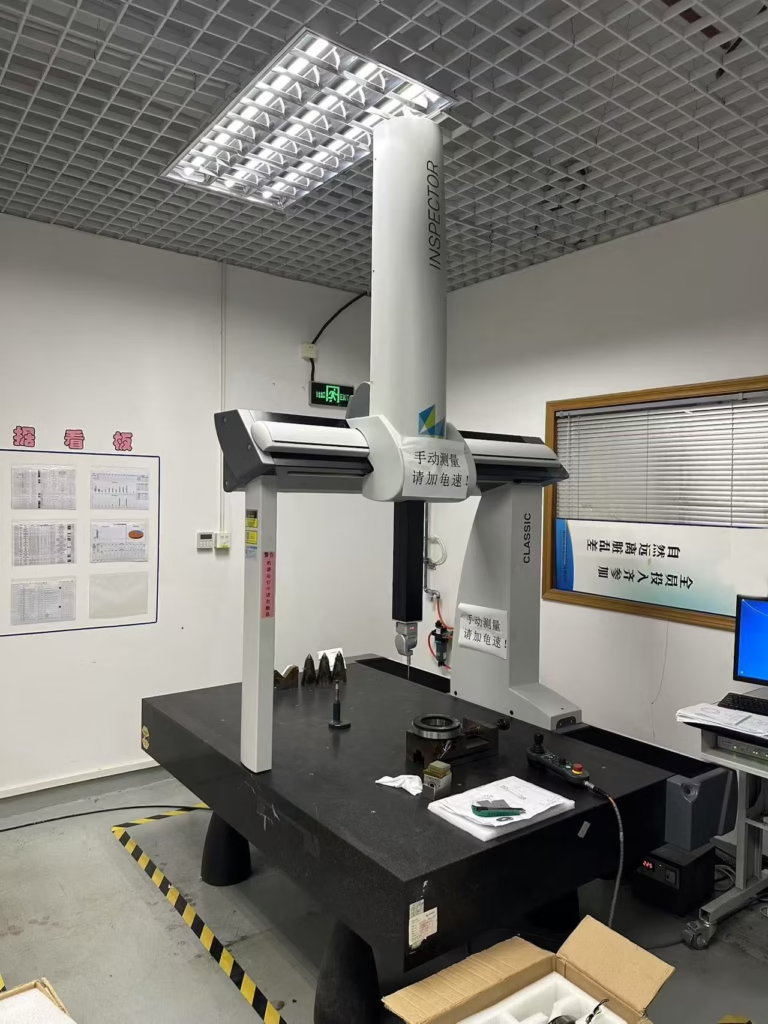

Our commitment to quality is backed by advanced technology. We utilize high-precision grinders and verify the results with state-of-the-art inspection tools, including CMMs, optical projectors, and surface roughness testers.

Grinding machine equipment for grinding processing

- Teléfono:+1 (859) 254-6589

- Correo electrónico:[email protected]

Precision, Verified.

We don’t just machine with precision; we prove it. Every turned component is subject to a rigorous quality control process, culminating in a final verification on our high-precision CMM to ensure it meets your exact specifications.

High-precision Digital Height Gauge

Three-dimensional Measuring Instrument

Three-dimensional Measuring Instrument

Your Grinding Questions, Answered

To assist with your design and sourcing process, we’ve answered some of the most common technical questions about precision grinding. If you need more information, our engineering team is always ready to help.

The key is how the part is held. Cylindrical grinding holds the part between centers, best for complex profiles and shoulders. Centerless grinding rests the part between wheels, ideal for high-volume production of simple parts like pins and rods.

Specify grinding when you need:

Tolerances tighter than ±0.01mm.

Surface finishes smoother than Ra 1.6 μm for functional reasons.

To machine hardened materials (over 50 HRC).

Proper grinding induces beneficial compressive stress on the surface, which significantly increases a part's fatigue life. Our strict process control completely eliminates the risk of "grinding burn," ensuring optimal material integrity.

For best results and cost-effectiveness:

Leave stock: Allow for 0.1mm - 0.3mm of material for removal.

Add undercuts: Design reliefs for wheel clearance at shoulders.

Tolerance wisely: Apply tight tolerances only to critical features.

Key cost drivers include the tightness of the tolerance/finish, the type of material (harder materials are slower to grind), and the batch size (larger quantities reduce the per-part cost).

Yes, absolutely. This is a primary strength of grinding. We routinely machine hardened materials like tool steels and carbides up to 65 HRC and beyond.

Let's Achieve Your Most Demanding Specifications

Don’t let tight tolerances or surface finish requirements be a bottleneck. Partner with us to achieve the precision your project deserves.

Upload your files for a comprehensive quote from our grinding experts.

Take the first step today !

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.

-scaled.avif)

-scaled.avif)

-scaled.avif)