5-Axis CNC Machining Service

Manufacture your most complex parts without compromise. Our 5-axis services allow you to realize intricate designs with superior surface finishes and tight tolerances, all produced with the enhanced accuracy and efficiency of a single setup.

- Tight Tolerance Guaranteed

- Complex Geometry Capability

- Rapid Process Planning & Production

Pushing the Boundaries of Precision

5-axis machining represents a leap forward from conventional methods, offering solutions for parts once considered impossible to make. Understand our expert approach and discover how this advanced technology provides superior accuracy, a flawless finish, and unparalleled design freedom for your project.

Our Approach to 5-Axis Machining

Beyond the standard 3 axes, 5-axis simultaneous machining allows the cutting tool to move across five axes concurrently.

This enables the creation of highly complex shapes, deep undercuts, and organic contours that are impossible with conventional methods.

-

Unmatched Part Complexity Machine virtually any geometry, including complex curves and multi-faceted surfaces.

-

Higher Accuracy & Consistency Completing a part in a single setup eliminates errors associated with re-fixturing, ensuring exceptional accuracy.

-

Superior Surface Finishes The tool can always maintain an optimal angle to the part surface, resulting in a smoother, higher-quality finish.

The Advantages of a 5-Axis Machining Strategy

Investing in a 5-axis machining strategy can deliver significant returns for your project. By enabling more complex designs and reducing setups, this advanced technology offers key advantages in lead time, design freedom, and overall cost-effectiveness for intricate parts.

Our 5-Axis Capabilities at a Glance

The table below details the standard specifications of our 5-axis machining services. Our investment in advanced technology allows us to consistently meet these demanding parameters. If your project requires capabilities beyond what is listed, please contact our team to discuss a custom solution.

|

Feature

|

Zenithin's Specification

|

|---|---|

|

Equipment |

PRIMINER V9L 5-Axis Machining Centers (2 units) |

|

Max Part Size |

Ø600 x 400 mm |

|

Highest Precision |

± 0.01 mm |

|

Key Materials |

Aluminum (7075, 6061), Stainless Steel, Titanium, PEEK |

|

Typical Industries |

Aerospace, Medical, Automotive, Robotics |

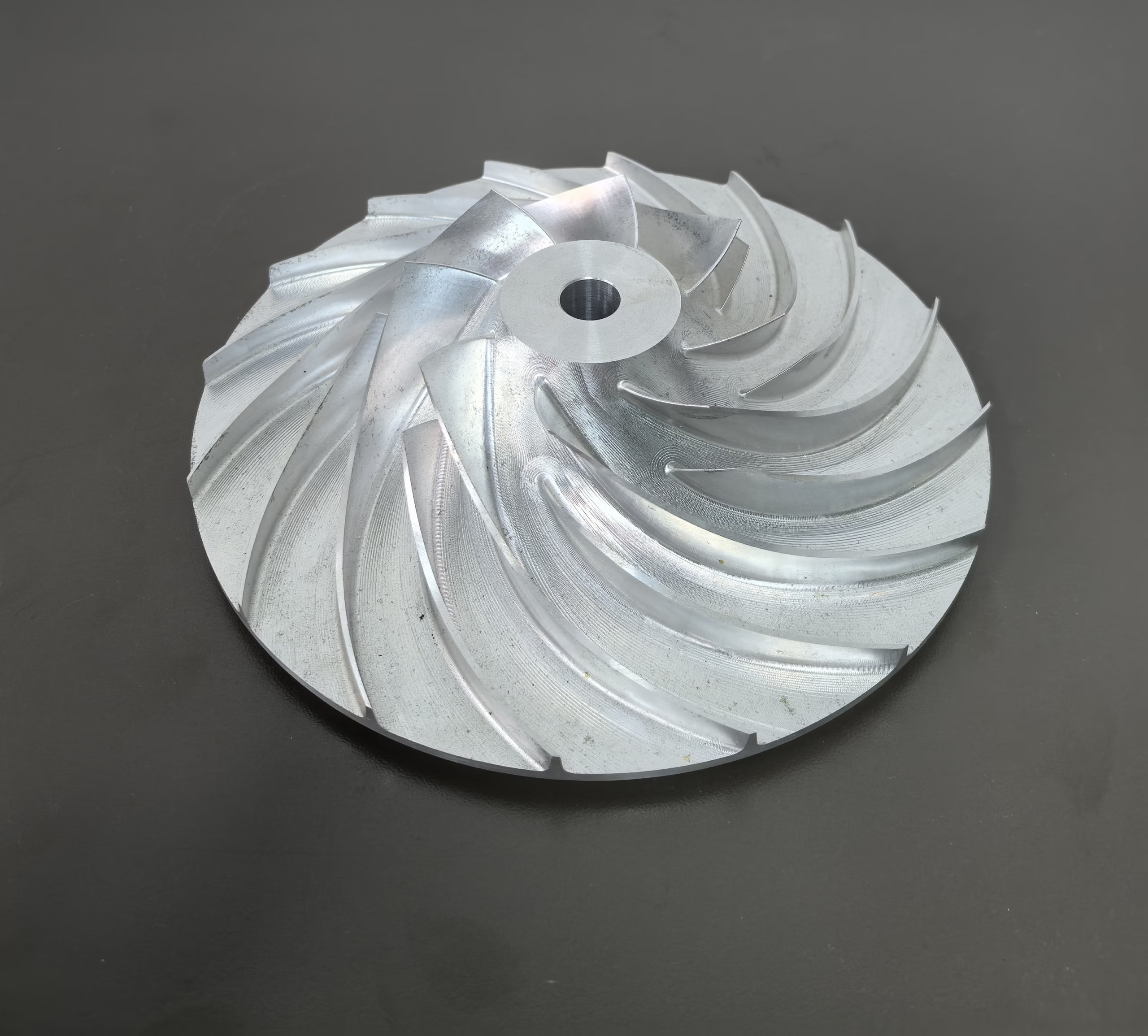

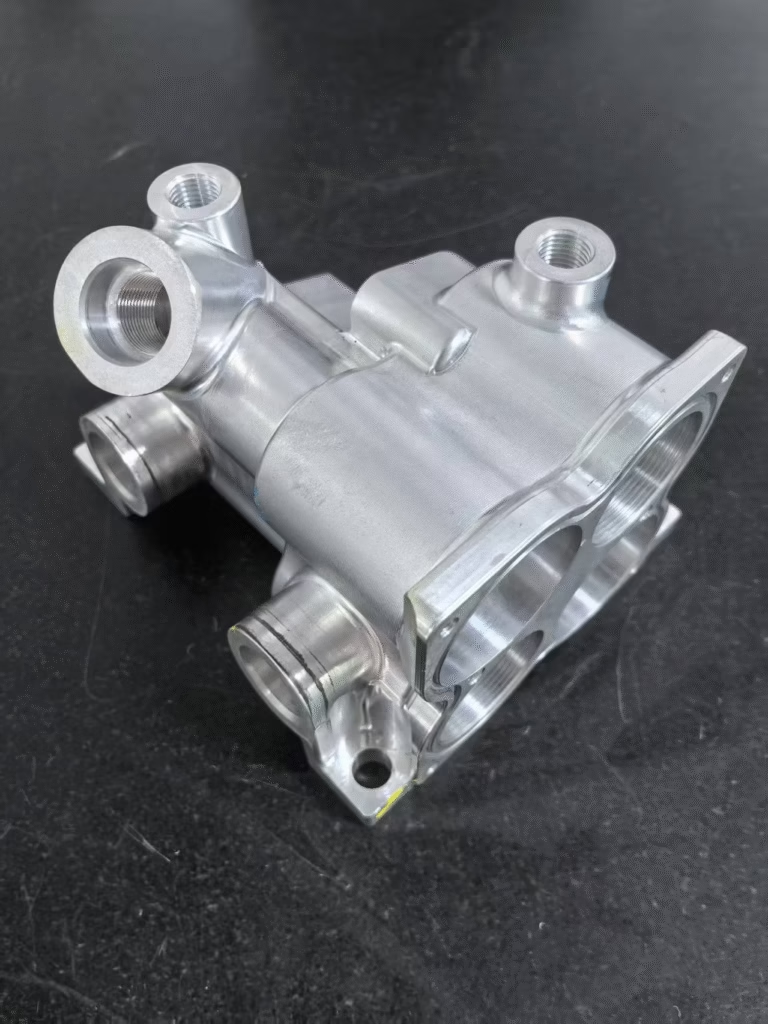

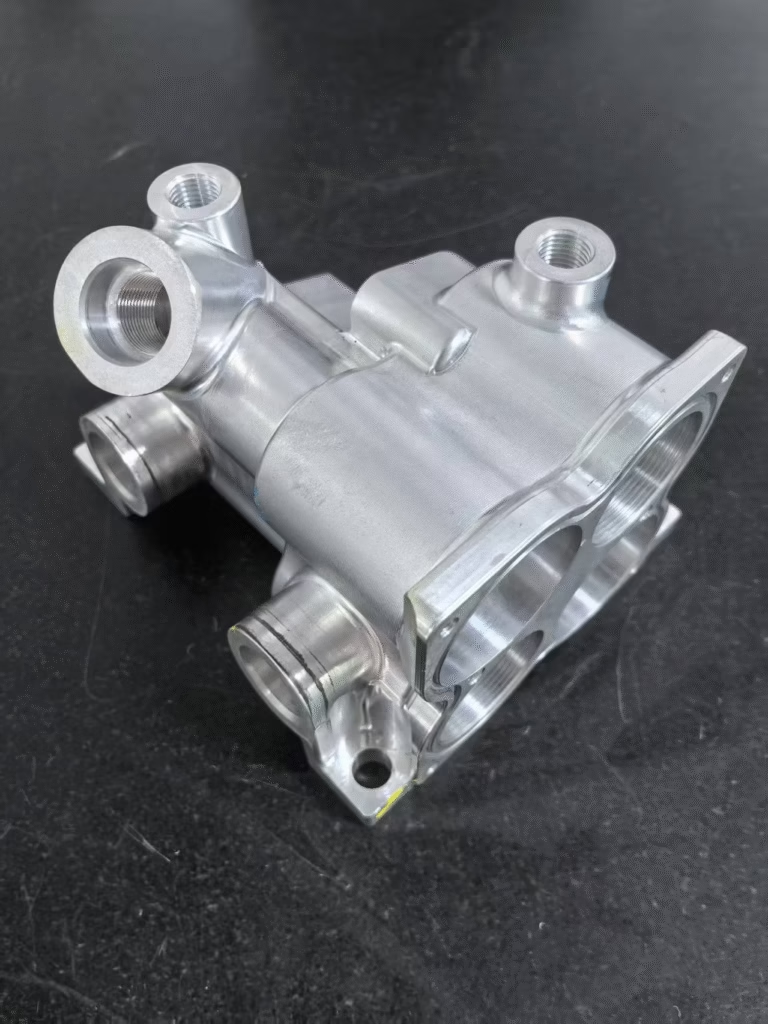

Our 5-Axis Showcase

Seeing is believing. This gallery features real-world parts produced on our advanced 5-axis machines, demonstrating our ability to tackle complex geometries and maintain tight tolerances in a single setup.

5-Axis Aluminum Connecting Arm

5-axis milled from Aluminum 6061 in a single setup, holding complex geometric tolerances (⊥/▱/◎) to 0.01mm with a clear anodized finish.

5-Axis Aluminum Connecting Arm

5-axis milled from Aluminum 6061 in a single setup, holding complex geometric tolerances (⊥/▱/◎) to 0.01mm with a clear anodized finish.

- Telefon:+1 (859) 254-6589

- E-Mail:[email protected]

Sandblasted 5-Axis Aluminum Box

Single-setup 5-axis milled from Aluminum 6061, holding 0.01mm geometric tolerances with a uniform sandblasted and clear anodized surface.

Sandblasted 5-Axis Aluminum Box

Single-setup 5-axis milled from Aluminum 6061, holding 0.01mm geometric tolerances with a uniform sandblasted and clear anodized surface.

- Telefon:+1 (859) 254-6589

- E-Mail:[email protected]

Chrome-Plated 5-Axis Steel Case

A robust 45# Steel case, 5-axis machined to hold both dimensional & geometric tolerances of ±0.01mm, and completed with a hard-wearing chrome plating.

Chrome-Plated 5-Axis Steel Case

A robust 45# Steel case, 5-axis machined to hold both dimensional & geometric tolerances of ±0.01mm, and completed with a hard-wearing chrome plating.

- Telefon:+1 (859) 254-6589

- E-Mail:[email protected]

Impressed by Our Work? Let's Build Yours

We are ready to apply the same precision and commitment to quality to your project. Upload your design files to get started with a free, no-obligation quote from our expert engineers.

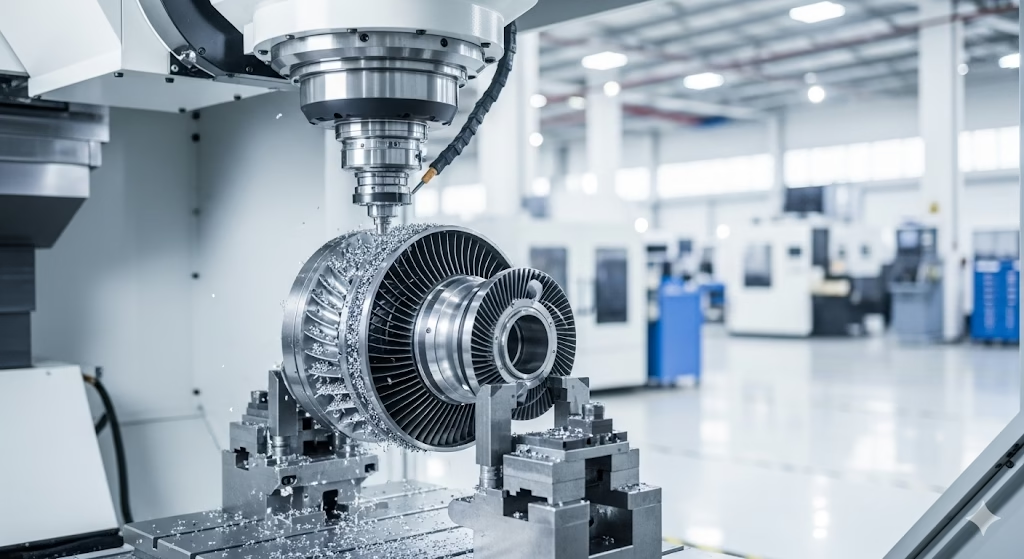

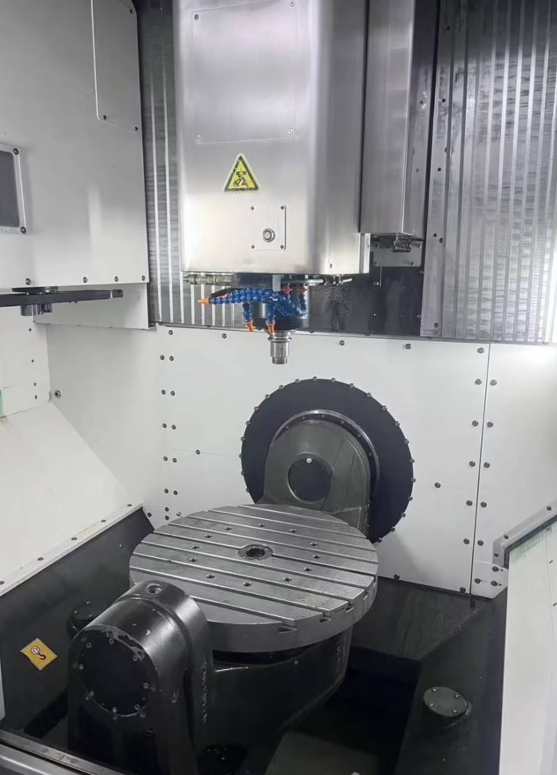

PRECISION

Powered by Advanced 5-Axis Technology

Our workshop is equipped with state-of-the-art PRIMINER V9L 5-axis simultaneous machining centers. This advanced technology is the key to producing parts with highly complex geometries and organic contours in a single, high-precision setup.

Five-axis CNC machining center

Five-axis CNC machining center

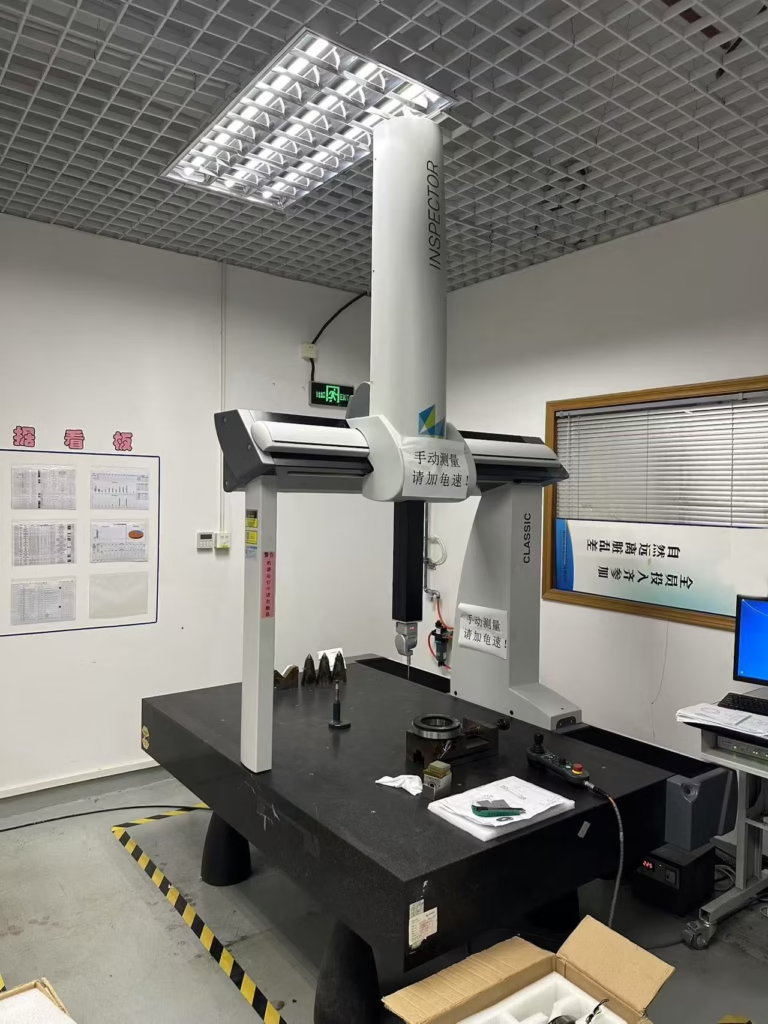

Precision, Verified.

We don’t just machine with precision; we prove it. Every component is subject to our rigorous quality control process, culminating in a final verification on our high-precision CMM to ensure it meets your exact specifications.

High-precision Digital Height Gauge

Three-dimensional Measuring Instrument

Three-dimensional Measuring Instrument

5-Axis Machining FAQ

To help you understand the unique capabilities and considerations of this advanced technology, we’ve answered some common questions about our 5-axis CNC machining services.

3+2 positions the part at an angle, then mills like a 3-axis machine. Simultaneous 5-axis, which we specialize in, moves all axes at once to create truly complex, contoured parts with superior finishes.

Not necessarily for complex parts. While the machine's hourly rate is higher, 5-axis is often a more cost-effective solution overall because its single-setup process eliminates the time, cost, and errors of multiple setups.

This guide delivers a proven DfM framework for your tolerance drawings. It's a key part of a broader strategy for slashing CNC machining costs, leading directly to predictable budgets and profitable, on-time projects.

It's ideal for parts with complex, multi-sided geometries and 3D-contoured surfaces, such as aerospace impellers, turbine blades, and medical implants where accuracy and finish are critical.

No. Our 5-axis machines can process nearly any machinable material, including various grades of aluminum, stainless steel, and high-performance plastics like PEEK. We also specialize in titanium, and successful projects depend on applying the correct DfM principles for titanium.

While initial programming is more complex, the actual machining is much faster. This single-setup approach often results in a shorter overall lead time for complex components.

For the fastest quote, please provide a 3D CAD model (STEP/IGS format is best) and a 2D drawing that specifies all critical tolerances and surface finish requirements.

Ready to Tackle Your Most Complex Project?

Our team thrives on complexity. From aerospace components to medical devices, we leverage advanced 5-axis technology to turn your most challenging designs into reality.

Submit your files for a comprehensive quote and an expert engineering review.

Take the first step today !

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.