CNC Milling Service

Whether your project involves a complex, multi-faceted housing or an intricate, mission-critical component, our precision CNC milling services are engineered to bring your most ambitious designs to life.

We leverage advanced technology and expert craftsmanship to deliver parts with superior accuracy, impeccable surface finishes, and the guaranteed quality your project deserves.

- Tight Tolerance Guaranteed

- Complex Geometry Capability

- Rapid Process Planning & Production

Unlocking Design Possibilities with Precision Milling

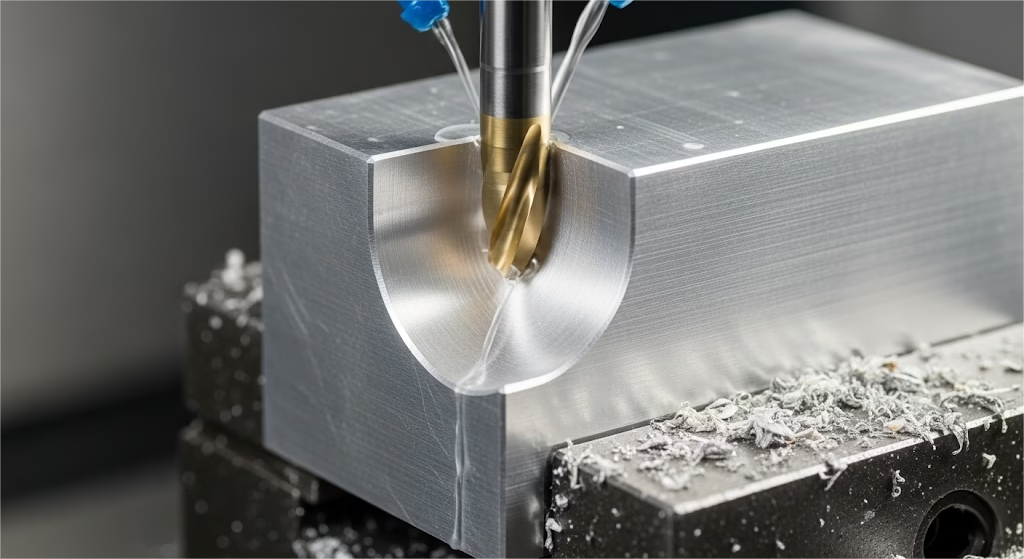

CNC milling is the cornerstone of modern manufacturing, offering unparalleled versatility and precision. Discover how our advanced milling services and expert approach can bring your most demanding designs to life.

Our Approach to Precision Milling

We view CNC milling as a blend of art and science.

It’s not just about removing material; it’s about strategic toolpath planning and a deep understanding of how materials behave, from standard metals to challenging ones detailed in our guide for machining titanium.

Our focus is on maximizing efficiency and surface finish while holding the tightest tolerances. We achieve this through our transparent 4-step process, ensuring your final part is a perfect reflection of your design intent.

-

Complex Geometries Capable of producing intricate shapes, complex contours, and high-tolerance features.

-

Material Versatility

Suitable for a wide range of materials, including a variety of metals detailed in our stainless steel selection guide, and engineering plastics.

-

High Efficiency We specialize in rapid process planning and efficient production setup for your projects.

Our CNC Milling Capabilities at a Glance

We believe in full transparency. Below is a detailed breakdown of our standard CNC milling capabilities. If your project requires specifications that exceed what is listed, we encourage you to contact our engineering team to discuss a custom solution.

|

Feature

|

Zenithin's Specification

|

|---|---|

|

Axes |

3-Axis, 4-Axis |

|

Max Part Size |

1000 x 800 x 500 mm |

|

Standard Tolerances |

ISO 2768-m (Medium/Fine) |

|

Highest Precision |

± 0.01 mm |

|

Best Surface Finish |

Ra 0.8 μm |

|

Materials |

Aluminum, Stainless Steel, Brass, Copper, Titanium, PEEK, ABS, PC... |

|

Lead Time (Prototypes) |

5-7 Business Days |

|

Lead Time (Small Batches) |

7-15 Business Days |

Our Milling Project Gallery

We believe our work speaks for itself. Below is a selection of CNC milling projects we have completed for clients across various industries, showcasing our commitment to quality and solving complex manufacturing challenges.

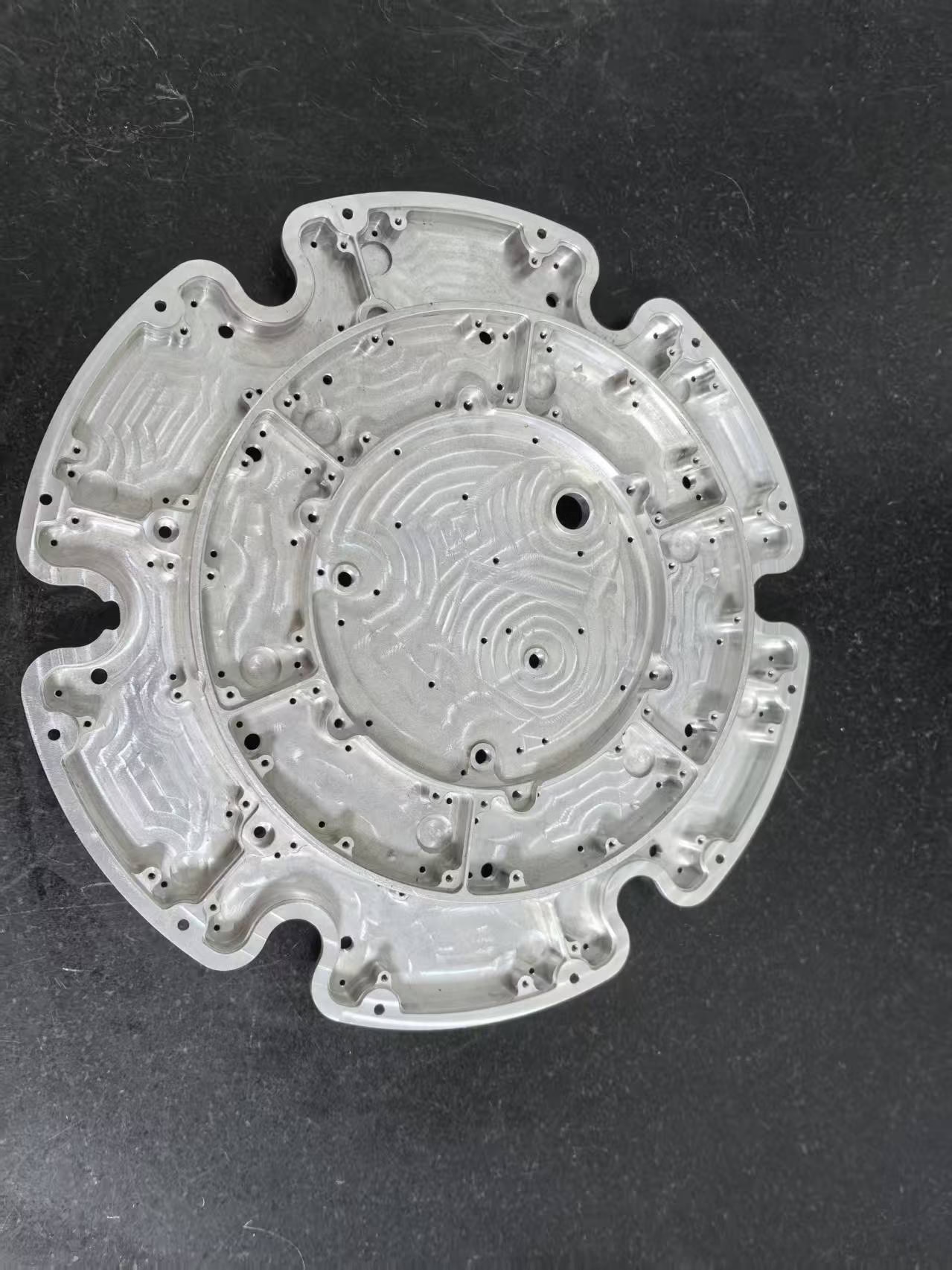

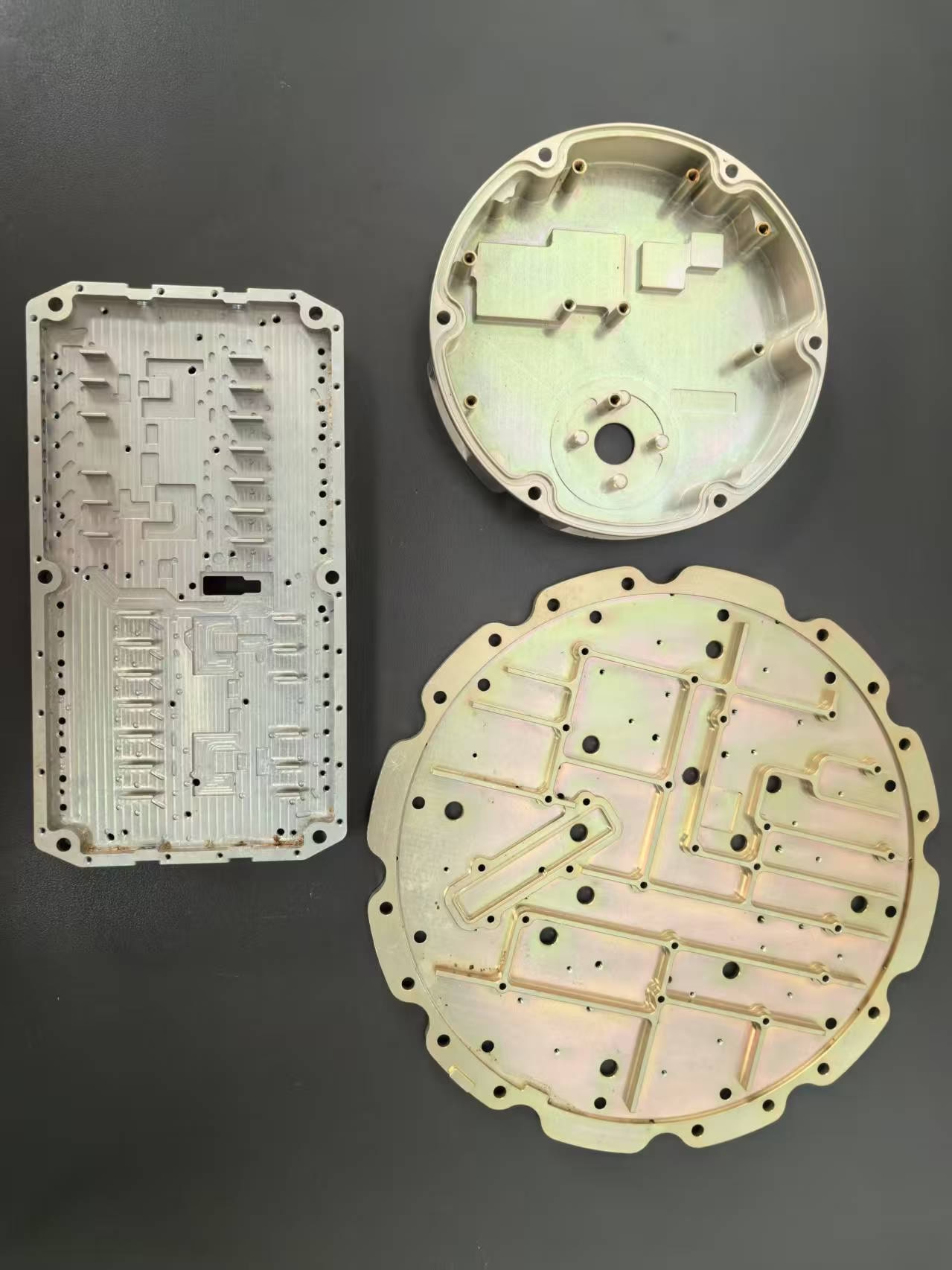

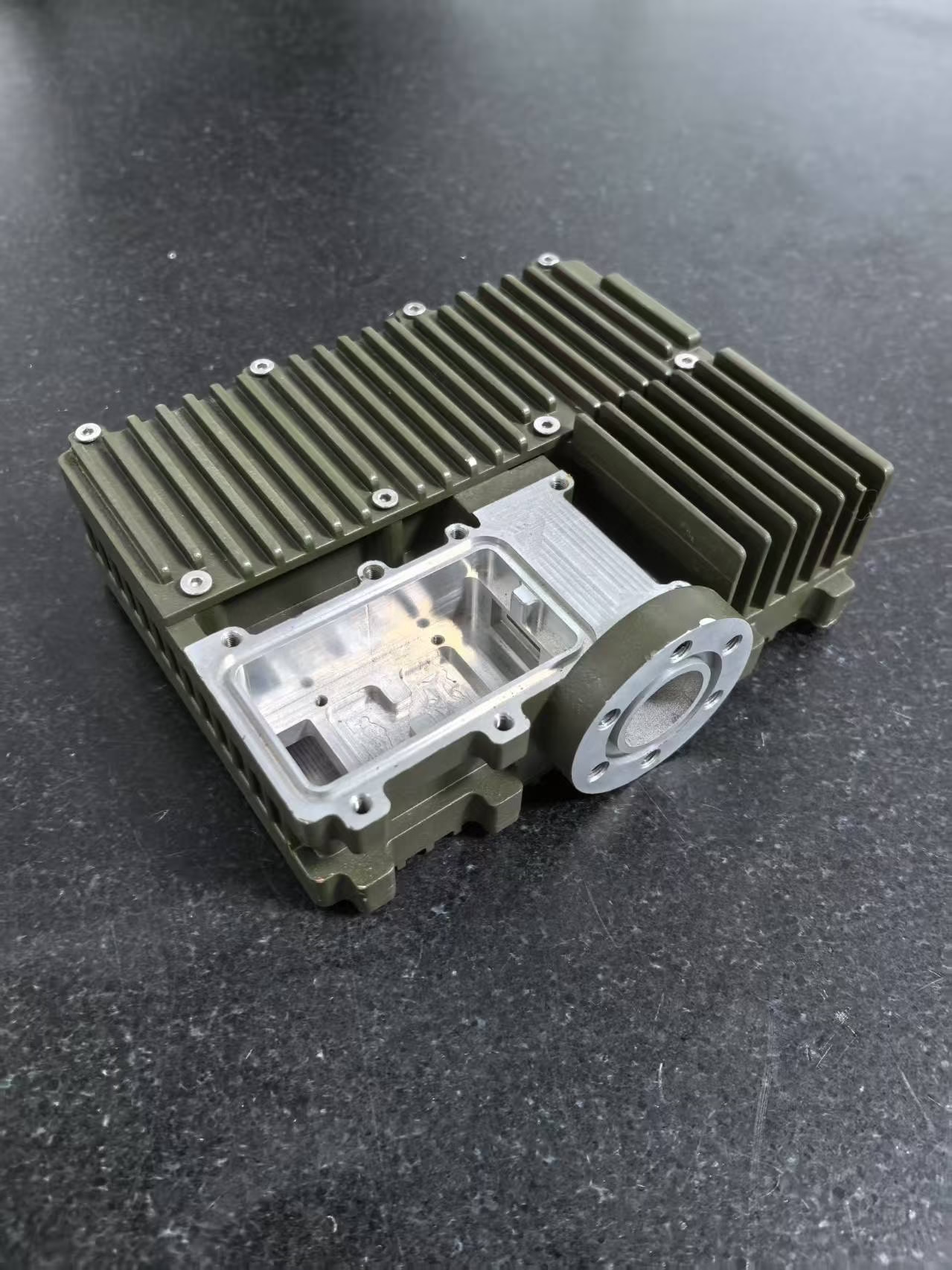

Complex Aluminum Housing

A complex housing produced with 5-axis CNC from Aluminum 7075 , featuring tight H7 tolerances and a clear anodized finish.

Complex Aluminum Housing

A complex housing produced with 5-axis CNC from Aluminum 7075 , featuring tight H7 tolerances and a clear anodized finish.

- Phone:+1 (859) 254-6589

- Email:[email protected]

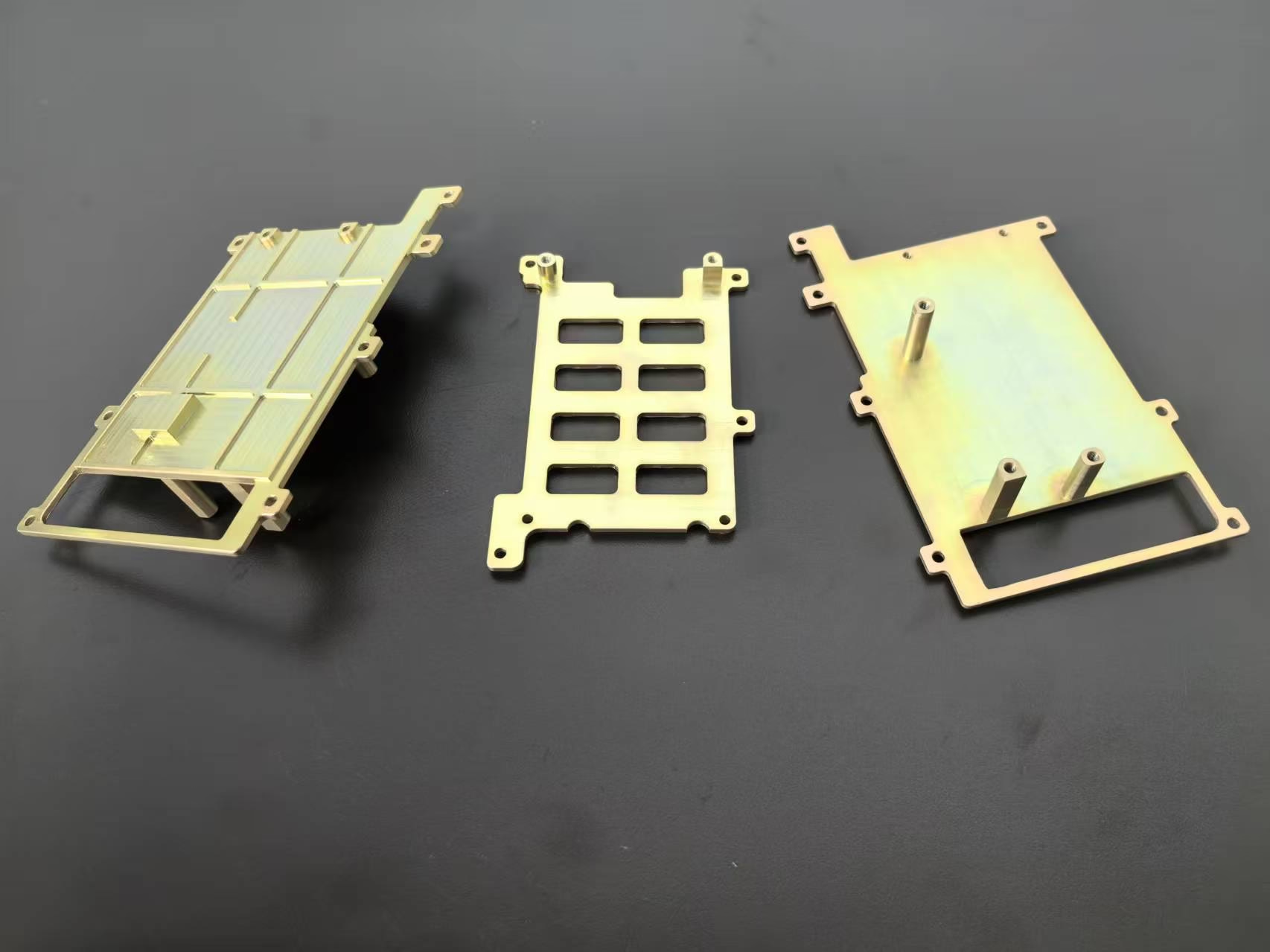

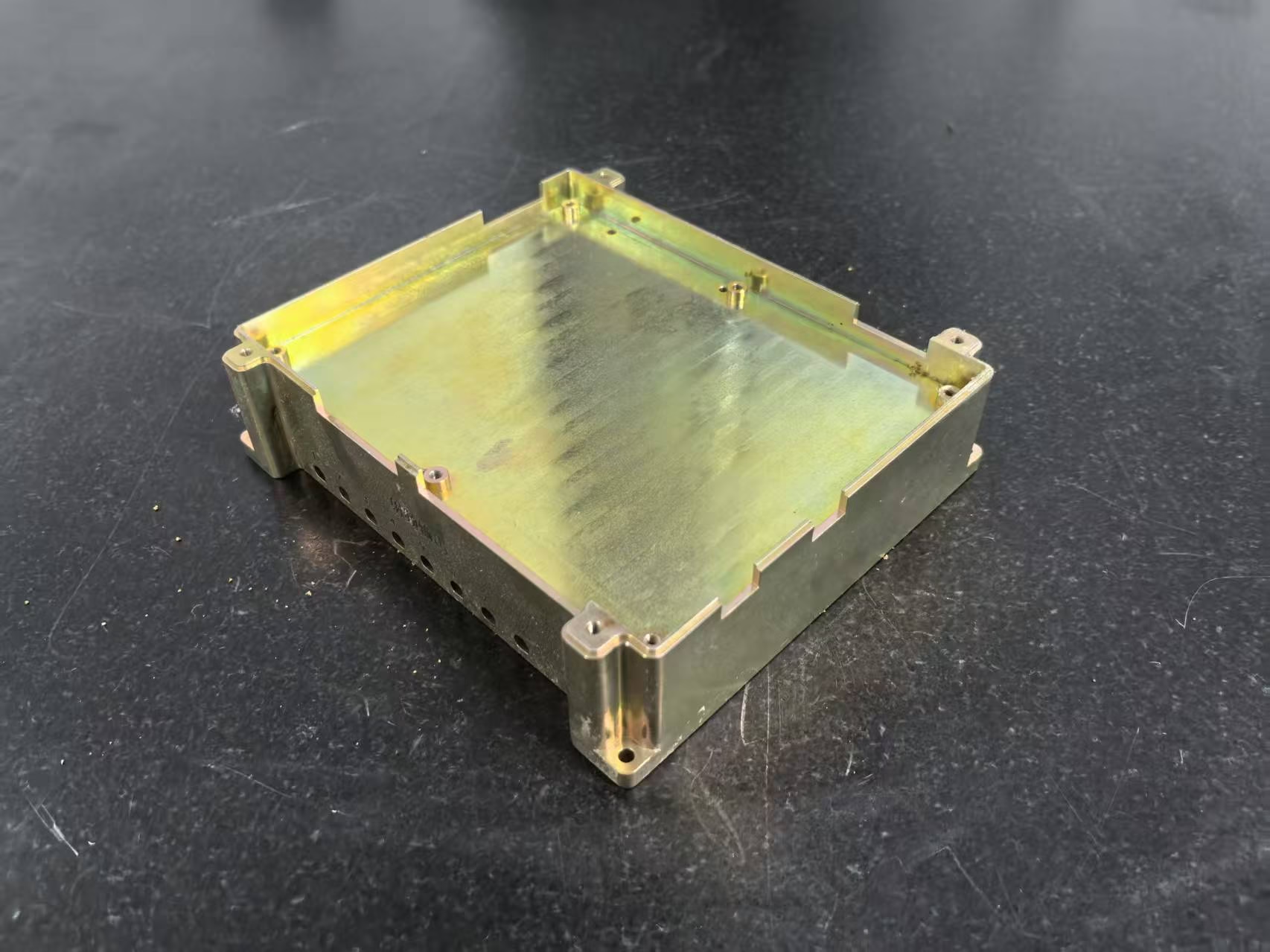

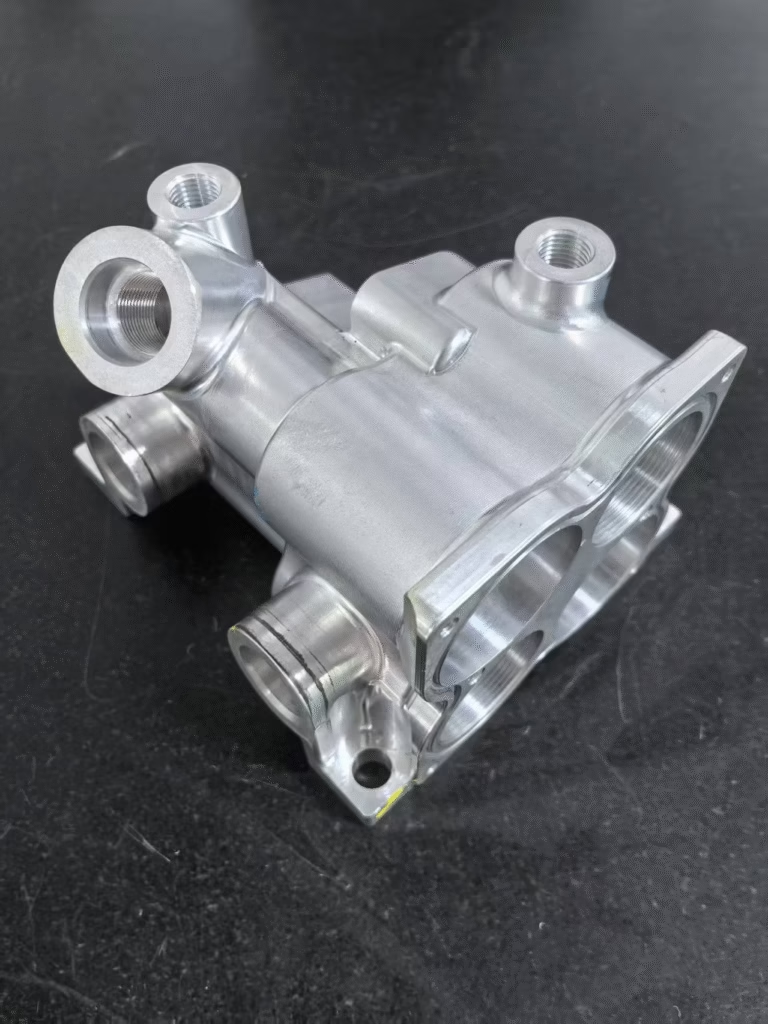

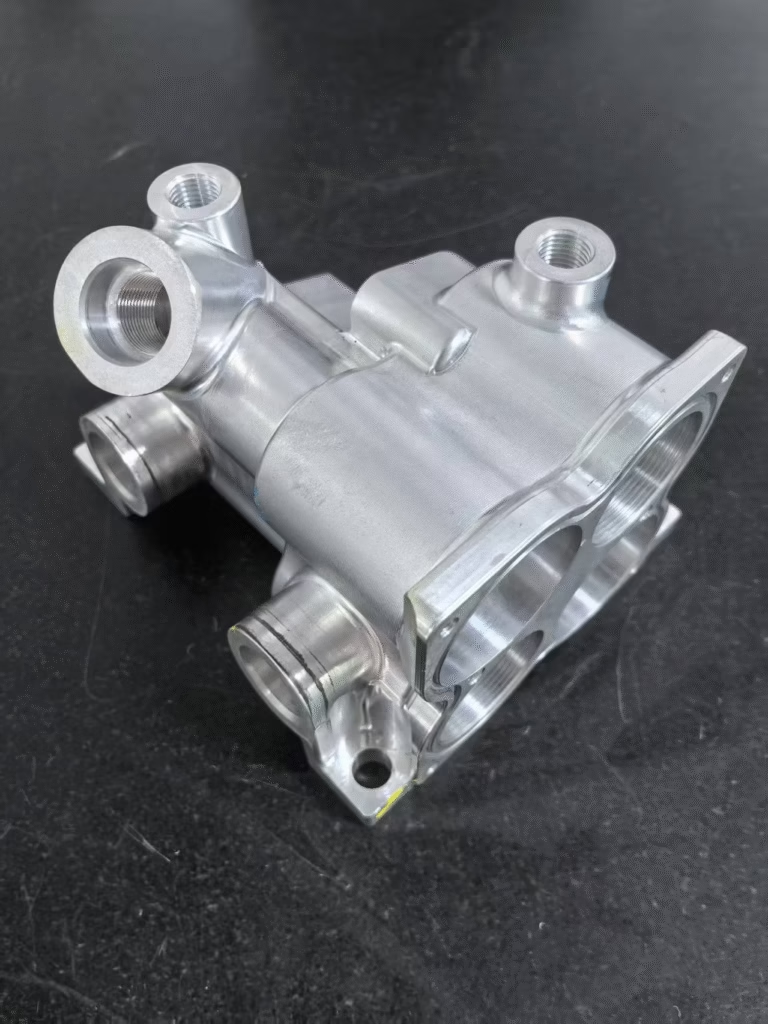

Custom Chrome-Plated Steel Flange

Multi-process machined from 45# steel (turning, CNC, drilling) and finished with chrome plating for superior wear resistance.

Custom Chrome-Plated Steel Flange

Multi-process machined from 45# steel (turning, CNC, drilling) and finished with chrome plating for superior wear resistance.

- Phone:+1 (859) 254-6589

- Email:[email protected]

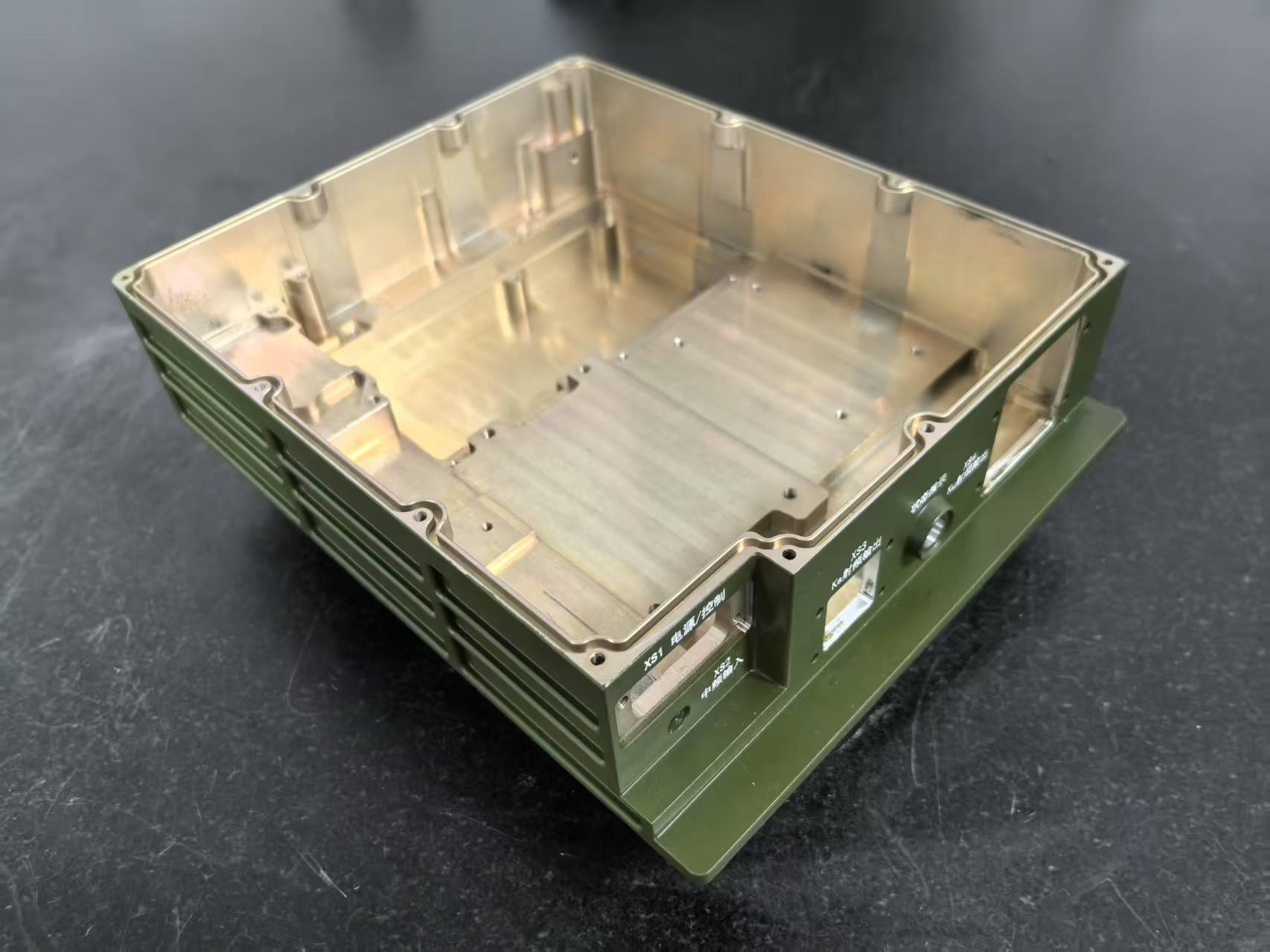

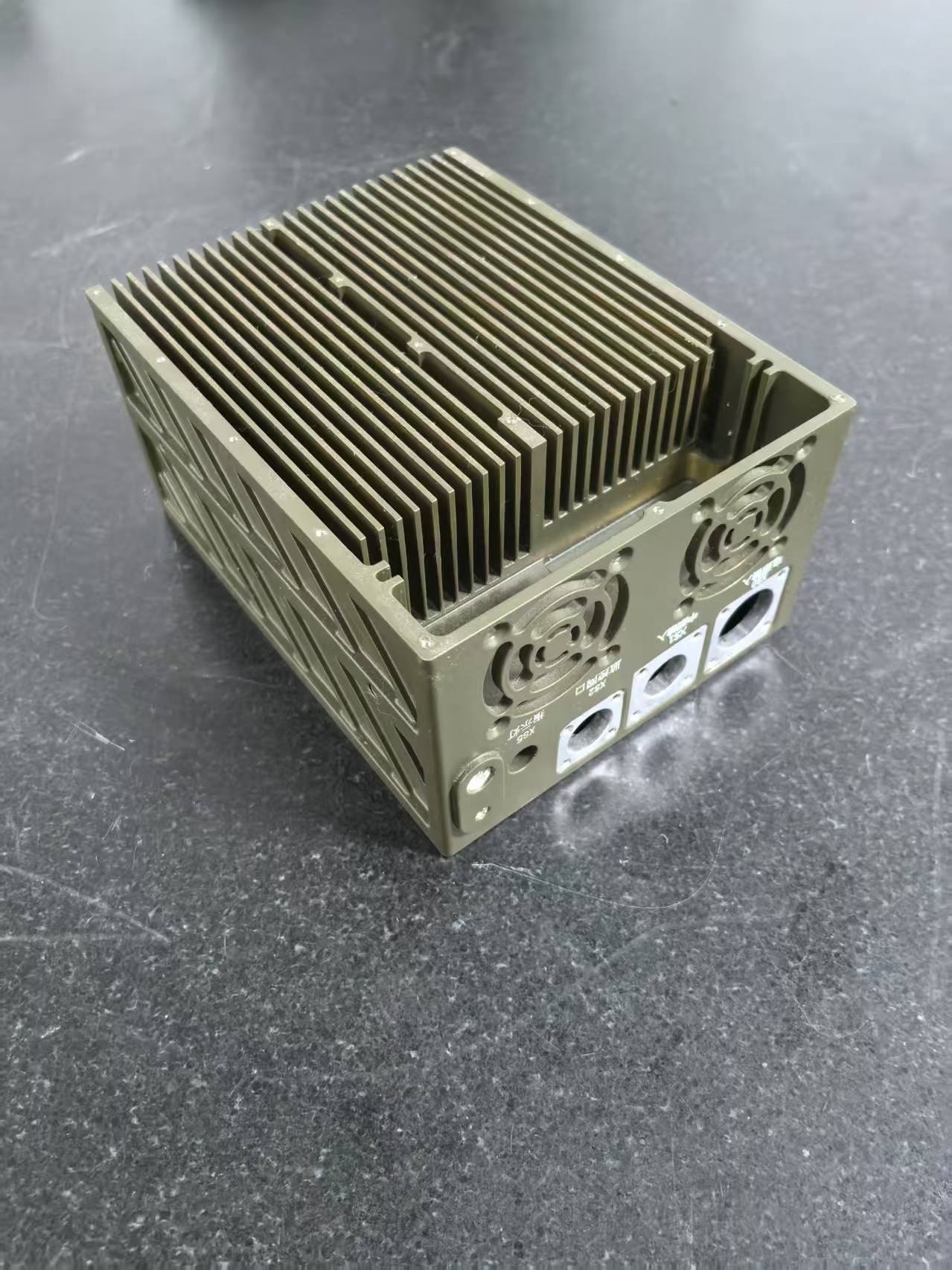

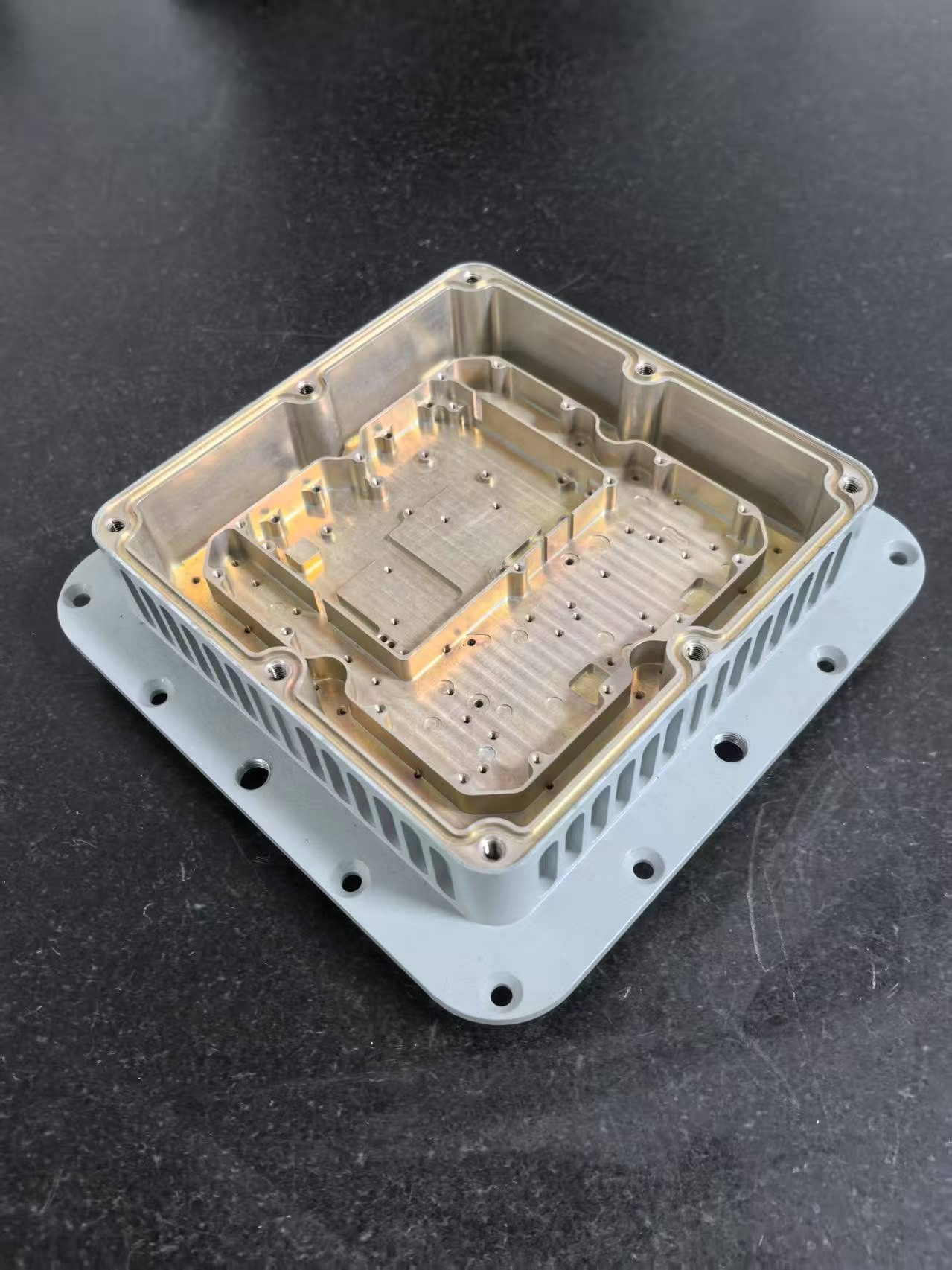

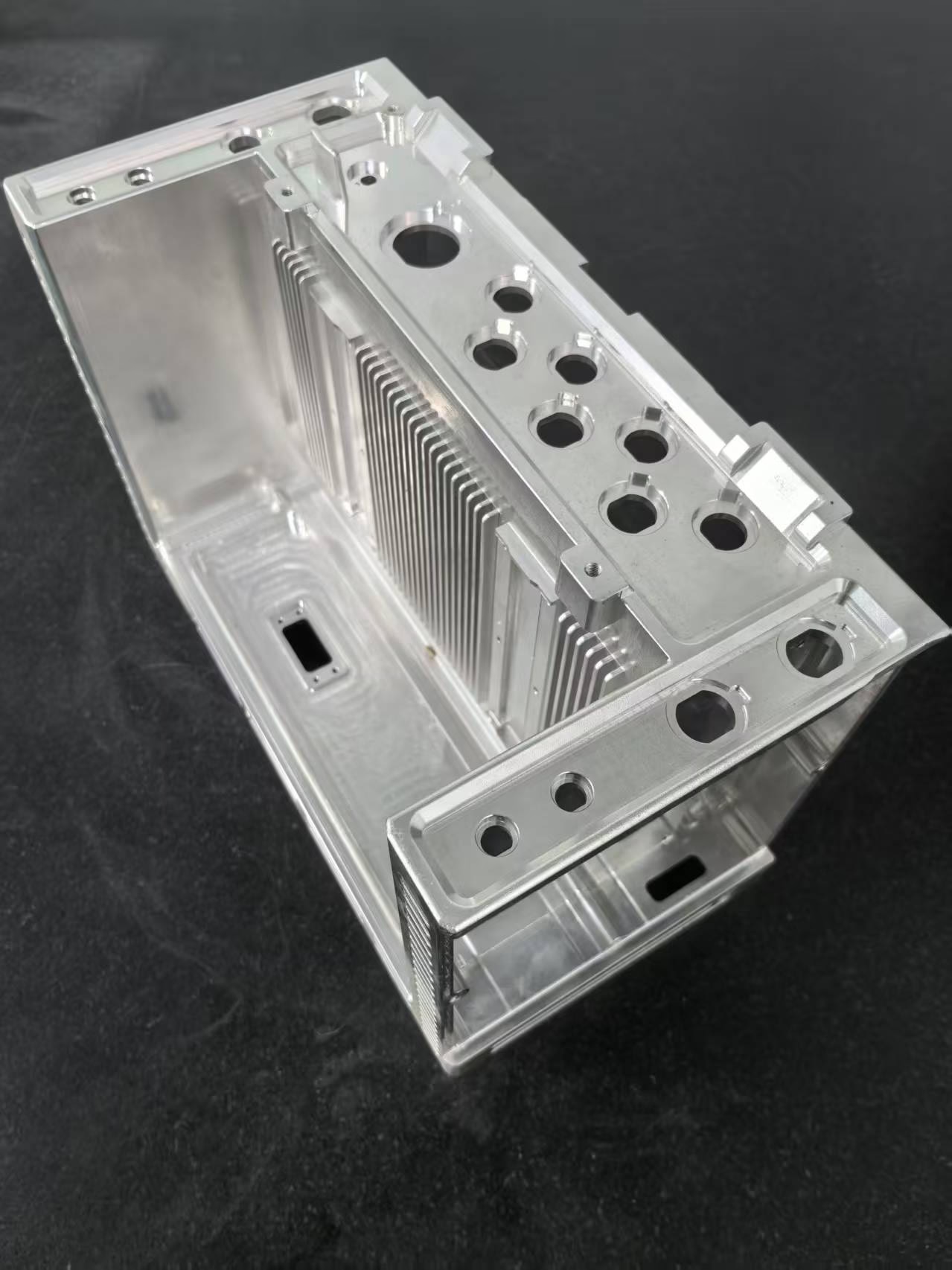

5-Axis Milled Aluminum Enclosure

A 5-axis milled enclosure in Aluminum 6061 , holding strict geometric tolerances (⊥/▱/◎ 0.01mm) for perfect alignment.

5-Axis Milled Aluminum Enclosure

A 5-axis milled enclosure in Aluminum 6061 , holding strict geometric tolerances (⊥/▱/◎ 0.01mm) for perfect alignment.

- Phone:+1 (859) 254-6589

- Email:[email protected]

Impressed by Our Work? Let's Build Yours.

We are ready to apply the same precision and commitment to quality to your project. Upload your design files to get started with a free, no-obligation quote from our expert engineers.

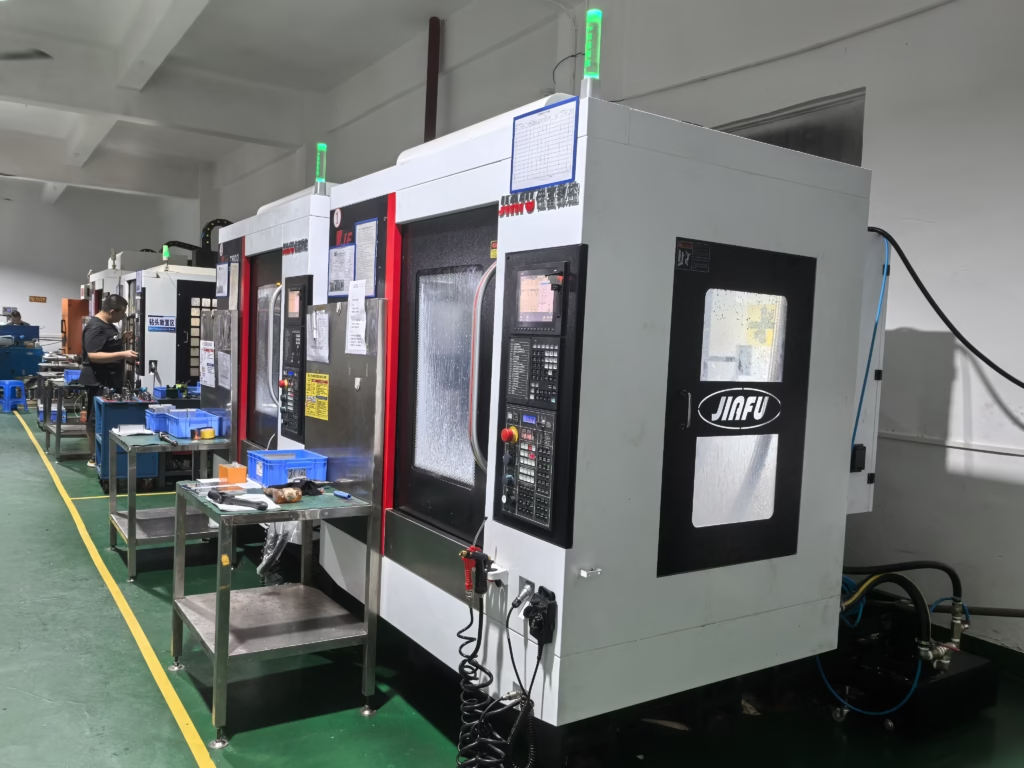

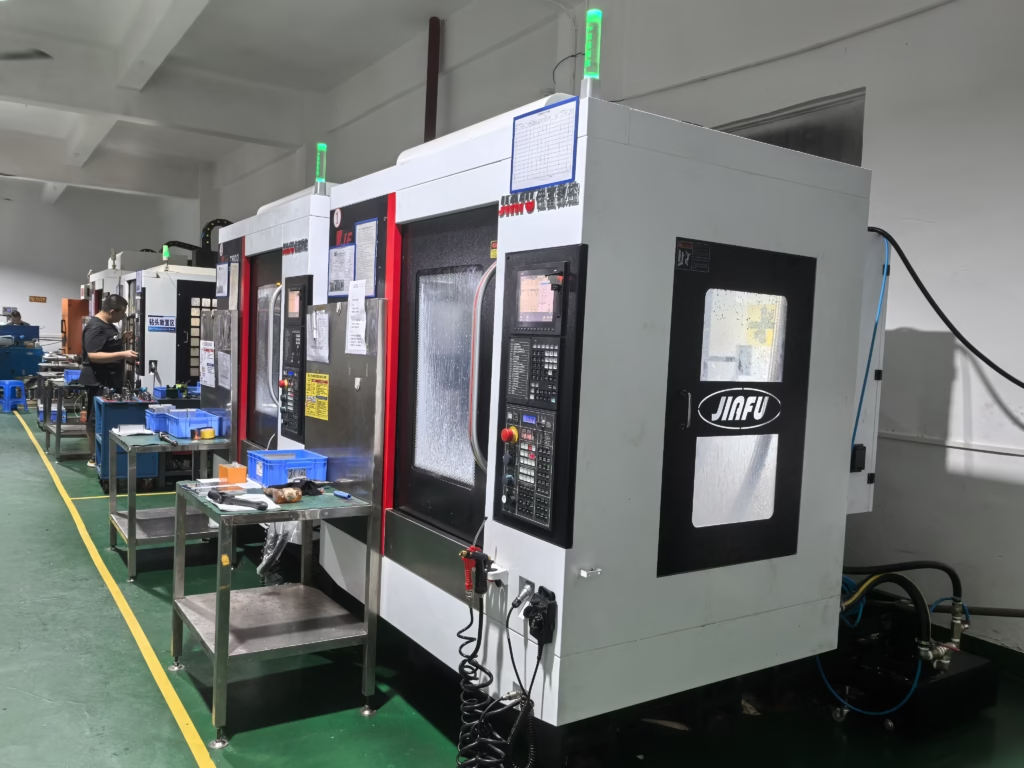

PRECISION

Powered by Advanced CNC Technology

Our workshop is equipped with a fleet of modern 3 and 4-axis CNC milling centers. We invest in high-quality equipment and regular maintenance to ensure consistent precision, efficiency, and reliability for every part we produce.

Harrison Hudson

CEO

Harrison Hudson

CEO

- Phone:+1 (859) 254-6589

- Email:[email protected]

Harrison Hudson

CEO

Harrison Hudson

CEO

- Phone:+1 (859) 254-6589

- Email:[email protected]

Harrison Hudson

CEO

Harrison Hudson

CEO

- Phone:+1 (859) 254-6589

- Email:[email protected]

Uncompromising Quality in Every Milled Part

Every milled part undergoes a rigorous inspection process, including final verification on our CMM equipment, to ensure it meets your exact standards.

Your Milling Questions, Answered

Find answers to common technical questions about our CNC milling services below.

3-axis milling operates on the X, Y, and Z axes. 4-axis adds rotation around the X-axis, allowing for machining on the sides of a part without new setups, which improves accuracy and efficiency.

This depends on the tool size and pocket depth, but we can typically achieve internal radii as small as 0.5mm. Please note this on your drawing if it's a critical feature.

Yes, we have extensive experience milling high-performance plastics. We use specialized tooling and techniques to manage heat and ensure dimensional stability, which is crucial when deciding between materials as explained in our PEEK vs. aluminum guide.

We recommend a minimum wall thickness of 1mm for metals and 1.5mm for plastics. Thinner walls are possible depending on material and part geometry, so please note it on your drawing for our DfM review.

The main cost drivers are Machining Time, Material Cost, Number of Setups, and the complexity of Tolerances. A crucial factor is also understanding the prototype vs. production cost, as volume dramatically impacts the per-part price.

Please specify the required surface finish using the Ra value (e.g., Ra 1.6 μm) on your drawing. Our standard as-milled finish is Ra 3.2 μm, but finer finishes are available upon request.

Let's Start Your CNC Milling Project

Whether it’s a single prototype or a low-volume production run, our team is ready to deliver.

Upload your design files to get a comprehensive quote and DfM analysis.

Take the first step today !

🔒 Your files are 100% secure and confidential. We gladly sign NDAs upon request.