Struggling to decide between 5-axis and 3+2 axis machining for your next critical project? This no-fluff guide helps you choose the right process based on total cost, quality requirements, and part complexity. Learn how to analyze supplier quotes like an expert and make a decision you can confidently defend to management.

3+2 axis machining, also known as indexed 5-axis, positions a workpiece at a fixed angle and then performs a 3-axis cutting operation. In contrast, simultaneous 5-axis machining involves all five axes moving concurrently to create complex contours. The key difference is that 3+2 is “position then cut,” while true 5-axis simultaneous machining is “cutting while in motion.

This guide breaks down how to choose the right machining process by analyzing your part, total project cost, and supplier capabilities.

- Understand the Core Difference: 3+2 is for positioning on angled faces; simultaneous 5-axis is for complex, continuous curves.

- Match Process to Part: Use geometry, tolerance, and surface finish needs to guide your choice—not just perceived complexity.

- Calculate Total Cost: Look beyond the initial quote to include costs of fixturing, setup time, and potential scrap risk.

- Interview Your Suppliers: Use specific technical questions to vet a supplier’s expertise, not just their equipment list.

- Build a Business Case: Justify your decision based on risk reduction and project speed, not just the per-part cost.

That’s the high-level summary. Now, if you want the advanced strategies and real-world examples that save money and prevent critical project delays, read on.

Foundational Knowledge: 3+2 Axis vs. 5-Axis Machining

To make an informed decision, you first need a solid understanding of what distinguishes these two processes beyond just the number of axes. The difference lies in how the machine uses its rotational axes.

Imagine a photographer taking your picture. 3+2 axis machining, also known as positional or indexed 5-axis machining, is like a photographer who first asks you to strike a pose (the two rotational axes lock the workpiece at a specific angle) and then takes a picture (the three linear axes perform the cutting operation). Once that shot is done, they ask you to change your pose for the next shot. The core principle is “position, then cut.”

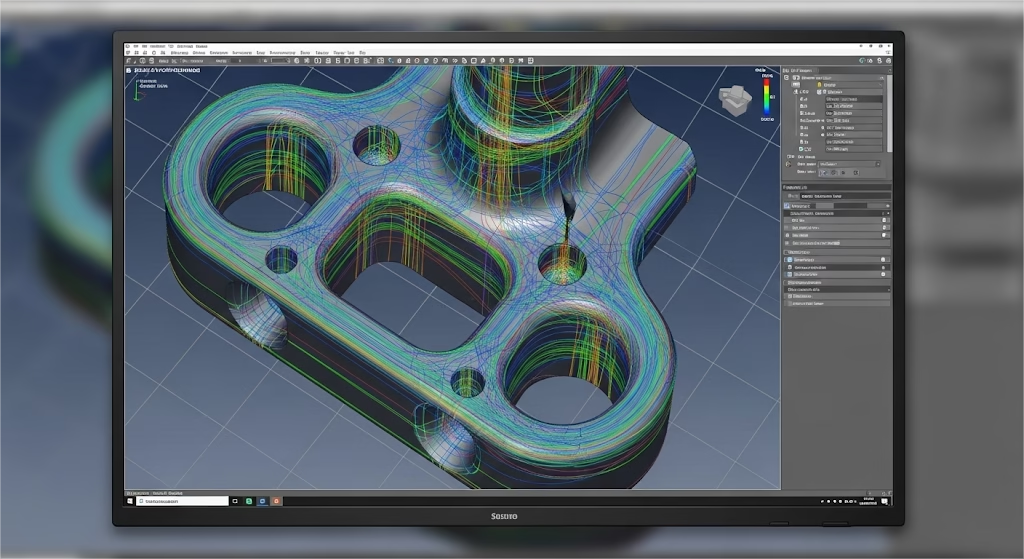

In contrast, simultaneous 5-axis machining is like a videographer filming a smooth, continuous tracking shot around you. The camera (the cutting tool) and you (the workpiece) can both move at the same time in a fluid, coordinated dance. The five axes—three linear (X, Y, Z) and two rotational (A, C)—all move concurrently. The core principle here is “cutting while in motion.”

Here is a clear comparison of their key attributes:

| Feature | 3+2 Axis Machining | Simultaneous 5-Axis Machining |

| Movement | Positions workpiece, then performs 3-axis cutting. | All five axes move at the same time. |

| Programming | Simpler; often an extension of 3-axis programming. | More complex; requires specialized CAM software. |

| Best For | Parts with multiple features on different angled faces. | Parts with complex contours, undercuts, and organic shapes. |

| Accuracy | Good, but susceptible to tolerance stack-up from re-clamping. | Excellent; single setup eliminates re-clamping errors. |

| Surface Finish | Can show blend lines between setups. | Superior, continuous finish without tool marks. |

| Limitations | Cannot create true complex curved surfaces. | Higher machine and programming costs. |

Decision Framework: Selecting the Right Process for Your Part

With a clear understanding of the two technologies, you can now analyze your specific part to determine the most suitable machining strategy. This isn’t about simply picking the most advanced option; it’s about matching the right tool to the job to achieve the optimal balance of cost, quality, and efficiency.

To do this, evaluate your part against three key criteria:

Part Geometry

The shape and features of your component are the most significant factors in your decision.

For parts with features on multiple flat faces at different angles (e.g., angled holes, pockets, or chamfers on a blocky housing), 3+2 axis machining is often the most cost-effective solution. The machine simply indexes the part to the correct orientation for each feature and then uses efficient 3-axis toolpaths.

For parts with complex, continuously curving surfaces (e.g., impellers, turbine blades, medical implants, or molds with organic shapes), simultaneous 5-axis machining is a necessity. It is the only way to produce these true contoured surfaces smoothly and accurately, as the tool can follow the curve in one continuous motion.

For parts with deep cavities or undercuts where a standard tool would collide with the workpiece, simultaneous 5-axis is critically important. The ability to tilt the tool or workpiece provides the necessary clearance to reach these “hidden” areas without using excessively long, vibration-prone tools.

Tolerance Requirements

Your design’s precision requirements play a crucial role. Every time a part is unclamped and re-fixtured, the risk of positional error—known as tolerance stack-up—increases.

If your part has tight positional tolerances between features on different faces (e.g., the alignment between a hole on top and a slot on a 45-degree face must be within ±0.01 mm), simultaneous 5-axis offers a significant advantage.

By completing all machining in a single setup, it eliminates re-clamping errors and ensures all features are precisely located relative to one another. This “one-hit” approach is a cornerstone of high-precision manufacturing.

Surface Finish Quality

Finally, consider the aesthetic and functional requirements for your part’s surface.

If your part requires a flawless, “tool-mark-free” surface finish, especially across complex curves, simultaneous 5-axis is the superior choice. It allows the use of shorter, more rigid cutting tools that vibrate less, and the ability to maintain an optimal tool angle relative to the part’s surface is a key factor in achieving a superior surface finish.

More importantly, the machine can constantly adjust the tool’s angle to maintain an optimal cutting position relative to the surface. This prevents the “scalloping” marks that can occur with 3-axis ball-end mills and results in a much smoother finish, often reducing the need for secondary polishing operations.

A common pitfall is over-engineering. I once worked with a talented engineer who insisted on 5-axis machining for a consumer product housing to achieve a perfect finish on a small decorative curve.

After analyzing the design, we realized that 95% of the part could be made efficiently on a 3-axis machine. By suggesting a minor simplification to that single curve, we reduced the manufacturing cost by 70% without impacting the product’s commercial success. This serves as a reminder: always align the technical requirements with the part’s core function and commercial goals.

Cost-Benefit Analysis: Justifying Your Decision

Choosing a machining process is not just a technical decision; it’s a business decision. The initial quote is only one part of the total cost equation. A lower hourly rate for 3+2 axis machining can be misleading if it ignores hidden costs, while the premium for simultaneous 5-axis can often be justified by its downstream benefits.

To make a sound financial case, you need to look at the Total Cost of Ownership for the part, not just the price on the quote.

The Hidden Costs of 3+2 Axis Machining

While the hourly rate is lower, a 3+2 axis approach can introduce other expenses:

- Fixturing Costs: Each unique setup often requires a custom fixture to hold the part securely at the correct angle. For a part needing three or four setups, the cost of designing and fabricating these fixtures can quickly add up, sometimes running from $500 to over $5,000.

- Setup Time: The labor and machine downtime involved in each re-clamping operation is a significant cost. For small to medium production runs, this setup time can account for a substantial portion of the total part cost.

- Risk of Scrap: Every time a part is handled and re-fixtured, the risk of human error and resulting scrap increases. A single scrapped part late in the production cycle means the loss of all previously invested time and materials. Industry experience shows this can contribute to a scrap rate of 5% to 15% in complex, multi-setup jobs.

The Hidden Value of Simultaneous 5-Axis Machining

Conversely, the higher price of 5-axis machining buys you more than just advanced motion. As Peter Zelinski, Editor-in-Chief of Modern Machine Shop magazine, points out, “The justification for a five-axis machine tool is almost never about the complexity of the parts. Instead, his business case for 5-axis machining focuses on how it solves process complexity by streamlining the entire production flow.”

Here is how to quantify its value:

- Elimination of Fixturing and Setup Costs: By completing the part in a single setup, you eliminate the costs associated with custom fixtures and multiple setup operations. This alone can sometimes offset the higher hourly rate.

- Reduced Cycle Time: For complex parts, 5-axis machining can reduce the overall cycle time by 20% to 40%. This is achieved by using more aggressive toolpaths, shorter tools, and eliminating the time spent moving the part between machines or setups.

- Reduced Risk and Improved Quality: The single-setup approach virtually eliminates the risk of re-clamping errors, ensuring higher, more consistent accuracy. This reduces the scrap rate to near zero and minimizes the need for costly quality control checks and potential rework.

When presenting your decision, frame it in these business terms. You are not just choosing a technology; you are investing in speed, quality, and risk reduction.

Supplier Evaluation: Choosing a True Manufacturing Partner

Receiving different quotes with different technical proposals can be one of the most confusing parts of the process. However, you can turn this challenge into an opportunity. Instead of viewing a quote as just a price tag, treat it as a technical interview that reveals a supplier’s true capabilities and problem-solving approach.

A low-cost quote based on 3+2 axis machining might indicate a shop that lacks 5-axis equipment or the programming expertise to use it effectively. Conversely, a high-priced 5-axis quote could mean the supplier is passing on the cost of their own uncertainty. The ideal supplier is not the one with the cheapest price, but the one with the best reasoning.

To uncover this, move beyond the price and start a technical dialogue. Ask your potential suppliers these critical questions:

- “Can you explain why you chose this specific machining strategy (3+2 vs. 5-axis) for my part?”

A quality supplier should be able to clearly articulate their reasoning based on your part’s geometry, tolerances, and features. This tests if they have truly analyzed your design. - “What are the primary risks or challenges if we were to use the other manufacturing approach?”

This question reveals the depth of their expertise. A true partner can discuss the trade-offs of both methods, showing they understand the full manufacturing landscape, not just the capabilities of their own machines. - “What CAM software do you use, and who will be programming this part?”

This gets to the heart of a key insight: you are not just buying machine time; you are buying the expertise of the CAM programmer. Top-tier software platforms are essential, as their advanced CAM strategies are what enable programmers to create the safe and highly efficient toolpaths needed for complex parts. - “Could you share examples or case studies of similar parts you have produced?”

This asks for direct evidence of their experience with the complexity and precision your part requires.

By asking these questions, you shift the conversation from cost to capability. The goal is to find a supplier who acts less like a simple vendor and more like an extension of your own engineering team. For a more detailed guide, please refer to our Checklist: 10 Things to Look for in a High-Precision Manufacturing Partner.

Conclusion: From Confusion to Confidence

Navigating the complexities of modern manufacturing no longer needs to be a source of uncertainty. You now possess a clear understanding of the fundamental differences between 3+2 axis and simultaneous 5-axis machining.

More importantly, you have a practical framework to analyze your part’s geometry, tolerance, and surface finish requirements, allowing you to move past the initial quote and evaluate the total cost and value of each approach. You are now equipped to make a confident, data-driven decision that balances technical excellence with your project’s budget and timeline.

The final step is to apply this knowledge to your specific design. If you would like an expert opinion, we invite you to take that step with us.

Upload your CAD file to our secure portal, and our engineering team at Zenithin will provide you with a complimentary Design for Manufacturability (DFM) analysis. Make your next decision on 5-axis vs. 3+2 axis machining not with uncertainty, but with the full confidence of an expert manufacturing partner by your side.