Tired of CNC machining projects that go dark the second production starts? We’ve developed a battle-tested 4-step process for your CNC machining project that eliminates uncertainty and puts you back in control. This is the exact workflow we use to ensure every part is delivered on time and to spec.

A transparent 4-step CNC machining process turns a complex project into a predictable workflow. It begins with a DFM-driven Quote, followed by a detailed Project Kickoff to align all technical specs. Next, proactive Production Control provides regular updates, and it concludes with a final Inspection & Delivery that includes a full quality documentation package.

Now, I’m going to break down each of these four steps in detail. You’ll see real-world case studies of how this process prevents costly errors and learn the single most important question to ask any potential supplier.

Why Process Matters More Than Machinery

When evaluating a CNC machine shop, it’s easy to be impressed by a long list of state-of-the-art equipment. But here’s an industry insight: the most advanced 5-axis mill is only as good as the system that runs it.

This is why we operate on a core philosophy of “Process over Plant.” A pristine machine running a flawed program will only produce expensive scrap metal faster. True quality and reliability come from a robust, well-defined process.

The legendary quality management pioneer, W. Edwards Deming, put it best: “If you can’t describe what you are doing as a process, you don’t know what you’re doing.”

A clearly articulated process isn’t just a document; it’s proof of competence. It demonstrates that a company is organized, in control of its operations, and capable of delivering consistent results, project after project.

A great process is fundamentally a system for eliminating risk. It’s designed to achieve “First Time Right,” a concept perfectly illustrated by the 1-10-100 Rule. This manufacturing principle states that preventing an error costs $1, correcting it during production costs $10, and fixing it after it has reached the customer costs $100.

Our process is built around that initial $1 investment—thorough planning and transparent communication—to save you from the far greater costs of rework, delays, and headaches down the line. It’s about systematically removing waste, not just from the material, but from the workflow itself.

A Transparent Journey from Your Design to a Finished Part

Step 1: Inquiry & Quote

When you send us your files, you’re not just getting a quote; you’re initiating the first crucial step of a successful manufacturing project. Our process begins the moment we receive your technical package.

Our engineers immediately conduct a preliminary Design for Manufacturability (DFM) analysis to identify any potential challenges or opportunities for optimization. We then clarify any technical questions before delivering a comprehensive quote with no hidden costs.

We learned the importance of this rigor the hard way. Early in our history, we quoted a project based on what looked like a simple 3D model. Only after work began did we receive a 2D drawing specifying a critical hole tolerance of ±0.005mm, a requirement that demanded a completely different, more expensive machining process. That experience was a powerful lesson.

From that day forward, we made a technical consistency review a mandatory part of our quoting process. A professional quote is the first promise we make on a project’s success, not just a number on a page.

To help us fulfill that promise, here’s how you can prepare an impeccable RFQ package:

- Provide Both 3D and 2D Files: A 3D model (like .STEP) is essential, but a 2D PDF drawing is where you define critical details like GD&T, surface finish, and specific tolerances.

- Be Specific on Materials and Finishes: Instead of just “Aluminum,” specify “Aluminum 6061-T6.” The more detail, the more accurate your quote and the final part.

- Communicate unspoken needs: Let us know the part’s final application or which surfaces are cosmetic. This context helps us make better manufacturing decisions on your behalf.

Step 2: Project Kickoff

Once your order is confirmed, we immediately assign a dedicated project manager to your project, who follows a robust process for managing complex projects.

This isn’t just a point of contact; this is your advocate and single source of truth from start to finish.

The first thing they will do is schedule a project kickoff meeting with you and our technical team. In this meeting, we confirm the final manufacturing drawings, clarify all instructions, and establish a detailed production schedule.

Why are we so meticulous at this stage? Because we learned that manufacturing perfection begins with communication perfection. We once produced a batch of beautiful aluminum enclosures for a medical device company. Every dimension was flawless, and the inspection report was perfect. Yet, the parts were rejected.

The reason? A tiny clamp mark on a non-functional surface that the client considered a critical cosmetic face—a detail that was never explicitly noted on the drawing.

That experience taught us that unspoken assumptions are the enemy of quality. Now, the kickoff meeting is where we make the implicit explicit. Your project manager will review your drawings with you, asking crucial questions like:

- “Which surfaces are cosmetic and must be free of any blemishes?”

- “Are there any sharp edge requirements?”

- “What are the key features for assembly?”

This is our communication commitment to you. Your project manager will establish a clear communication schedule, including how frequently you’ll receive updates. We’ll also define a transparent Engineering Change Order (ECO) process, so if a design needs to be modified mid-production, you’ll know exactly what to expect in terms of cost and timeline adjustments.

This step is about building a shared understanding to ensure the parts we deliver meet not just your drawings, but your expectations.

Ready to Streamline Your Next Project?

Our process is designed for clarity and precision. See how our expert CNC Milling and Turning services can bring your designs to life without the communication headaches.

Step 3: Production Control

Once production begins, our commitment to transparency becomes even more critical. This is where many projects fall into the “black box,” but our process is designed to keep you fully informed.

We conduct First Article Inspections (FAI) for all critical processes, and your project manager provides proactive progress updates through weekly reports or real-time notifications at key milestones. Most importantly, we have a risk-alert system for immediate communication if any issues arise.

We believe that bad news doesn’t get better with time. In a time-sensitive project for an automotive client, a key 5-axis machine went down unexpectedly, threatening a two-day delay. Instead of trying to hide the problem, our project manager notified the client’s engineer within an hour of the incident.

He presented two clear options: switch to another machine with a slight compromise on a non-critical surface finish, or wait for the repair and accept the delay.

Because of our immediate and transparent communication, the engineer had ample time to adjust his team’s assembly schedule and confidently chose the first option. He later told us what he valued most wasn’t that we were perfect, but that we were honest and proactive when things weren’t.

In manufacturing, the most damaging news is the news you hear at the last minute.

This brings us to a key insight for modern manufacturing: information accessibility is more important than physical proximity. A local supplier with poor communication can leave you more in the dark than a manufacturing partner across the country with a great system. Our process is built on this principle.

Through our project management system, you have a real-time, online window into your project’s status, ensuring you are always in control, no matter where you are.

Step 4: Inspection & Delivery

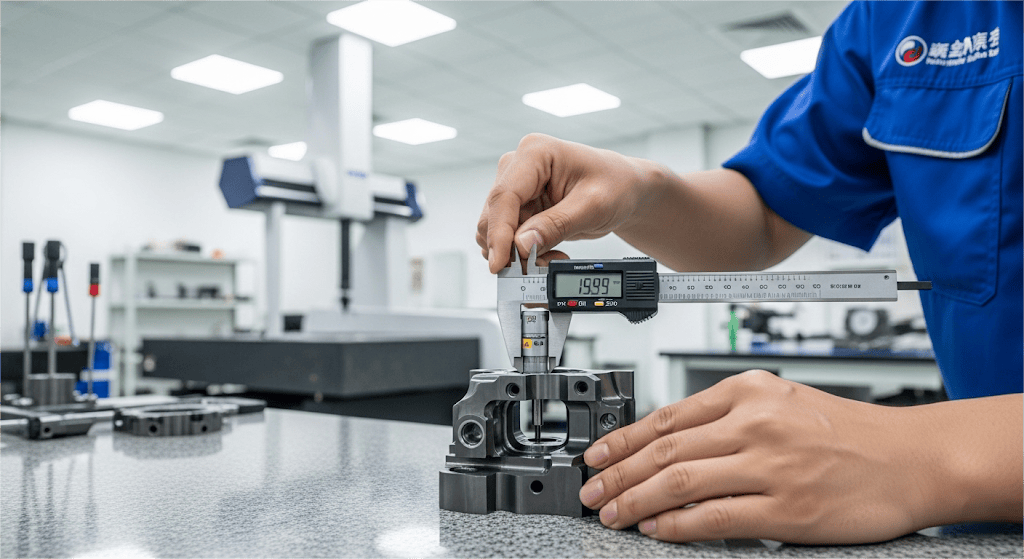

The final step of our process is designed to ensure that what you receive is not just a part, but a complete solution backed by verifiable proof of quality. Every project undergoes a 100% final inspection before it leaves our facility.

We then compile a comprehensive quality documentation package, professionally pack your parts for secure transit, and provide full logistics tracking. But our job doesn’t end at shipment; we proactively follow up to gather your feedback, ensuring the parts perform exactly as you intended in their final assembly.

This commitment to documented quality has a tangible impact. We once worked with a client who was struggling with an assembly issue. While our parts fit perfectly, a component from another supplier was causing misalignment. They couldn’t identify the root cause.

As part of our standard delivery, we had provided a detailed Coordinate Measuring Machine (CMM) report for our component. Using our report as a baseline, their quality team was able to pinpoint the exact dimensional error in the other supplier’s part, saving them weeks of frustrating trial and error.

This is why we believe in delivering proof, not just promises. When you receive a shipment from us, you’ll know exactly what’s in the quality package that accompanies your parts:

| Process Step | Your Key Takeaway | Core Deliverable |

|---|---|---|

| 1. Inquiry & Quote | Risk-free, accurate pricing | DFM Analysis & Formal Quote |

| 2. Project Kickoff | Total alignment before production | Dedicated Project Manager |

| 3. Production Control | Full visibility, no surprises | Proactive Updates & FAI |

| 4. Inspection & Delivery | Verifiable quality in hand | Full Quality Documentation |

- Material Certificates: Full traceability for the raw materials used in your project.

- Full Dimensional Inspection Report: A detailed report verifying that every feature on your part meets the specifications of your drawing.

- Certificate of Conformance (CoC): Our official certification that the parts meet all your stated requirements.

- Specialized Reports (as needed): Depending on your project, this can include CMM reports for complex geometries or FAIR (First Article Inspection Reports).

This documentation package is more than just paperwork. It’s a tool that simplifies your receiving inspection, provides confidence for your assembly teams, and delivers the trust you need to move your project forward.

Building a Lasting Partnership

Ultimately, the value of a transparent process extends far beyond the delivery of a single part. It’s about what you gain back. By eliminating the “engineer’s time tax,” you reclaim countless hours that can be reinvested in design, innovation, and your next big project.

It’s about the confidence that comes from predictable outcomes, allowing you to manage timelines and budgets effectively. And it’s about protecting your professional reputation by partnering with a supplier who delivers on their promises, every time.

This approach transforms the traditional client-supplier relationship. As Dr. Jeffrey K. Liker, a leading expert on lean manufacturing, notes, the best suppliers are those who feel like an extension of your own company.

We don’t see ourselves as just another vendor on your approved supplier list; we aim to be a genuine partner in your success. Our goal is to build a long-term, collaborative relationship based on trust and mutual benefit, not short-term price advantages.

This partnership is built on a continuous improvement loop. The feedback you provide after a project is complete is invaluable. It’s fed directly back into our system to refine our processes, enhance our communication, and ensure that with every new project, our collaboration becomes even more seamless and efficient.

We’re not just making your parts; we’re building a better way to work together.

Conclusion: Choose Your Workflow, Not Just Your Parts

When you select a supplier, you’re choosing more than just a vendor; you’re choosing a way of working. You’re deciding how your time will be spent, how your projects will be managed, and how much certainty you can have in your outcomes.

Our transparent 4-step process for your CNC machining project is engineered for professionals like you who value precision, efficiency, and control. It’s designed to eliminate the friction and ambiguity that so often bog down manufacturing projects, freeing you to focus on what you do best.

Have a complex project or specific technical questions?

Schedule a free, 15-minute technical consultation with one of our senior engineers. We’re here to provide the expert guidance you need to move your project from design to reality, seamlessly.

Ready to Start Your Project with Confidence?

You have the vision. Let our transparent process and expert engineers handle the manufacturing with the precision your project deserves.

References & Notes

[1] The 1-10-100 Rule: This rule is a widely accepted quality management principle illustrating that the costs of preventing errors are far lower than the costs of correcting them after they have occurred. It is often cited in contexts related to the Cost of Quality (CoQ).

[2] W. Edwards Deming: An American engineer, statistician, and management consultant who is considered a foundational figure in modern quality control. His philosophies, particularly the Plan-Do-Check-Act (PDCA) cycle, are cornerstones of manufacturing process improvement worldwide.

[3] Design for Manufacturability (DFM): An engineering practice of designing products in a way that they are easy to manufacture. The goal is to reduce manufacturing costs, improve quality, and shorten time-to-market by proactively addressing potential production issues during the design phase.